Earlier today I flattened the undersides of the 3 boards that will make up the top. It did not take long – an advantage of the planked top design, since you only have to worry about getting the boards reasonably flat, the idea being that any twist or bowing/cupping along the length will be removed...

Earlier today I flattened the undersides of the 3 boards that will make up the top. It did not take long – an advantage of the...

English workbench

Preparing for the top simply involves getting all the parts that receive the top planks flat and level.

Here is the bench glued and nailed up:

Getting things flat and level means using a plane – or in my case several.

Over the past couple of years I have bought and refurbished a number of old...

Preparing for the top simply involves getting all the parts that receive the top planks flat and level.

Here is the bench glued and nailed...

English workbench

glued and nailed – not a complicated job, but I rehearsed it just in case. What could go wrong I hear you ask? Well, nothing major but my nails were slightly too long and poked out the other side of the legs. I suppose only I will know but they lurk there nonetheless, waiting to impale...

glued and nailed – not a complicated job, but I rehearsed it just in case. What could go wrong I hear you ask? Well, nothing major...

English workbench

The rigidity of an English workbench is provided by aprons: the legs fit inside housings in the apron preventing the bench from twisting.

A possible disadvantage of this design is that the joints can become loose over time and a suggested improvement – from Paul Sellers – is the addition of wedges:

When I have made benches...

The rigidity of an English workbench is provided by aprons: the legs fit inside housings in the apron preventing the bench from twisting.

A possible...

English workbench

The final two things I did over the weekend were to attach the top bearers to the legs and also to clean up my vice, which I bought last April. Once I removed all the crud, paint, dried oil etc and applied some lubricant it works very well and there does not seem to be...

The final two things I did over the weekend were to attach the top bearers to the legs and also to clean up my vice,...

English workbench

I finished the leg brace, and the result is a rather complex looking set of recesses on the front RHS leg – it is not as complex as it looks to do, since you are just doing a series of simple half lap dovetails.

I managed to avoid any major cock-ups today, but to make up...

I finished the leg brace, and the result is a rather complex looking set of recesses on the front RHS leg – it is not as...

English workbench

Although the legs looked passable when dry fitted the poor quality timber I used for the legs meant they split as soon as I tried to nail the aprons on.

Following some sage advice on the ukworkshop.co.uk forum I gave it up as a bad job and have started again with decent redwood....

Although the legs looked passable when dry fitted the poor quality timber I used for the legs meant they split as soon as I tried...

English workbench

I prepared the wood needed for the workbench legs – the fence posts were very ropey, and this contributed to my first major cock up. I am gradually getting more confident using a plane to get a board square and straight and this part went okay. Richard Maquire is good at explaining which surfaces need to...

I prepared the wood needed for the workbench legs – the fence posts were very ropey, and this contributed to my first major cock up. I...

English workbench

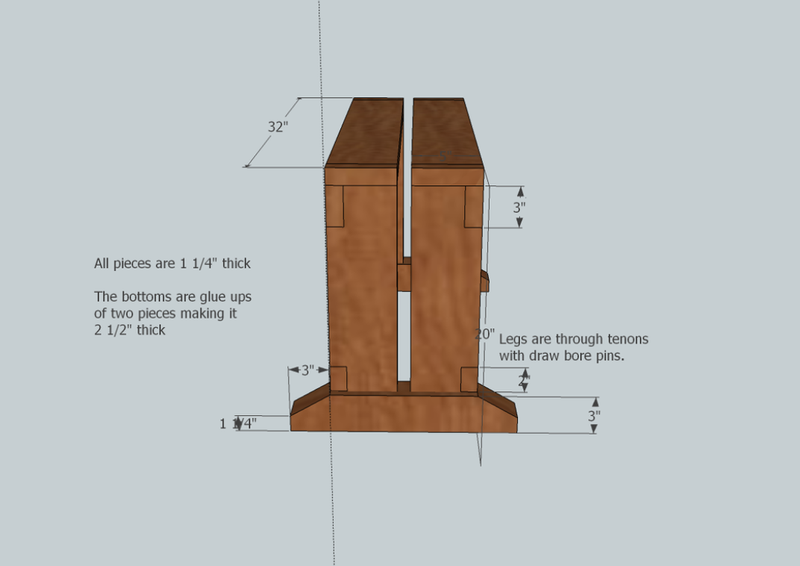

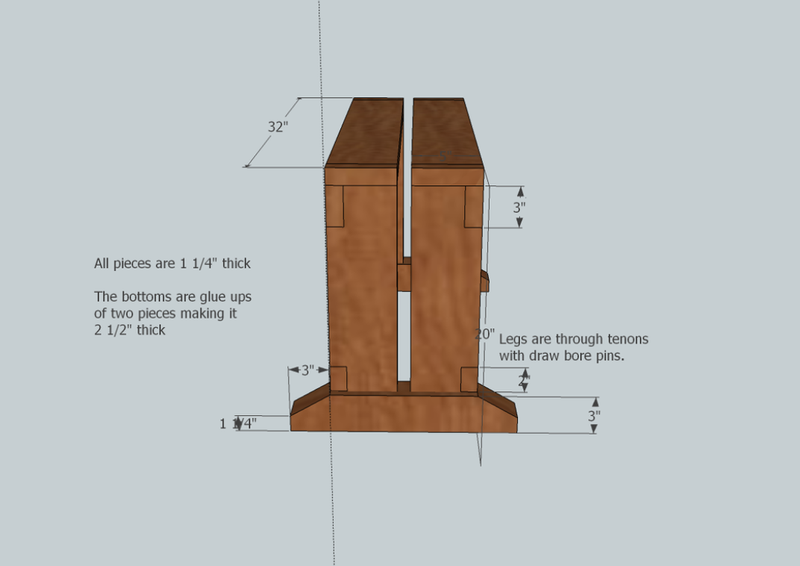

I am making what has become known as an English workbench. I’m not sure why this term became popular, possibly it is down to Chris Schwartz in his Workbench book where he identifies three broad traditions in bench design: French (oblong table with a heavy top); English (thin planks on top, one or more...

I am making what has become known as an English workbench. I’m not sure why this term became popular, possibly it is down to...

English workbench

the saw bench is surprisingly sturdy, but you can add two aprons to further brace the bench – they are attached with half lap dovetail joints.

I used a saw to remove the waste from the top part of the lap joints – what I meant to try (but forgot) was to have a go at splitting...

the saw bench is surprisingly sturdy, but you can add two aprons to further brace the bench – they are attached with half lap dovetail joints....

saw bench

You can strengthen the joints between legs and feet by ‘draw boring’. It is very easy to make your own dowels: I used a chisel to split a bit of an oak balustrade into roughly hexagonal pieces slightly larger that the 3/8” inch dowels I needed and then thumped them through a piece of...

You can strengthen the joints between legs and feet by ‘draw boring’. It is very easy to make your own dowels: I used a chisel...

saw bench

I am in the process of making a saw bench, my first attempt at making anything with hand tools. Needless to say I am making my fair share of mistakes.

I am making it from a couple of scaffold boards. The design is a bit convoluted compared to traditional saw benches, but hopefully this will...

I am in the process of making a saw bench, my first attempt at making anything with hand tools. Needless to say I am making...

saw bench

From the time Leonard Bailey introduced metal planes in the 1860s until quite recently they were supplied with thin irons. On paper this is a good thing: thin irons are an improvement on thick ones in as far as they are cheaper to make – since they use less material – and are easier to sharpen because...

From the time Leonard Bailey introduced metal planes in the 1860s until quite recently they were supplied with thin irons. On paper this is a...

bench planes

Although this article is about blades used in wooden planes there is an interesting parallel between the blade choices available to wooden plane users at the start of the 20th century and the choices facing metal plane users at the start of the 21st who must choose between thick vs thin irons.

Old wooden planes...

Although this article is about blades used in wooden planes there is an interesting parallel between the blade choices available to wooden plane users at...

bench planes

We already read about the importance of sharpening angles, camber is the other consideration when sharpening a plane cutter.

It is common to add a slight curve or “camber” when preparing a cutter to take off a lot of material – the curve means only a small section of the blade enters the wood initially and...

We already read about the importance of sharpening angles, camber is the other consideration when sharpening a plane cutter.

It is common to add a...

bench planes

Once you’ve ground the blade to to about the right angle then you need to hone it in order to create a keen edge. The experience of generations of craftsman has shown that grinding the blade at 25° and honing a few degrees steeper – around 30° – is a good practical approach for many woodworking...

Once you’ve ground the blade to to about the right angle then you need to hone it in order to create a keen edge....

bench planes