Following the previous articles about iron, steel and plane cutters it may be tempting to view laminated cutters as an historical curiosity from a forgotten era of wooden planes, wrought iron and crucible steel. However companies like Record and Stanley chose to use laminated irons in their metal planes right up until the 1950s.

What...

Following the previous articles about iron, steel and plane cutters it may be tempting to view laminated cutters as an historical curiosity from a forgotten...

bench planes

1⏎

at least in the 2nd half of the 19th century, see footnote below for some information about laminated irons made in the 20th

2⏎

pre decimalisation in the UK (1971), there were 12 pence in a shilling and 20 shillings in a pound

3⏎

this is a simplification, in practice, as suggested by the...

1⏎

at least in the 2nd half of the 19th century, see footnote below for some information about laminated irons made in the 20th

2⏎...

bench planes

Crucible steel was still in demand well into the twentieth century, despite competition from the spectacularly successful (and much cheaper) large-scale production processes introduced by Bessemer and Siemens.

Enduring qualities

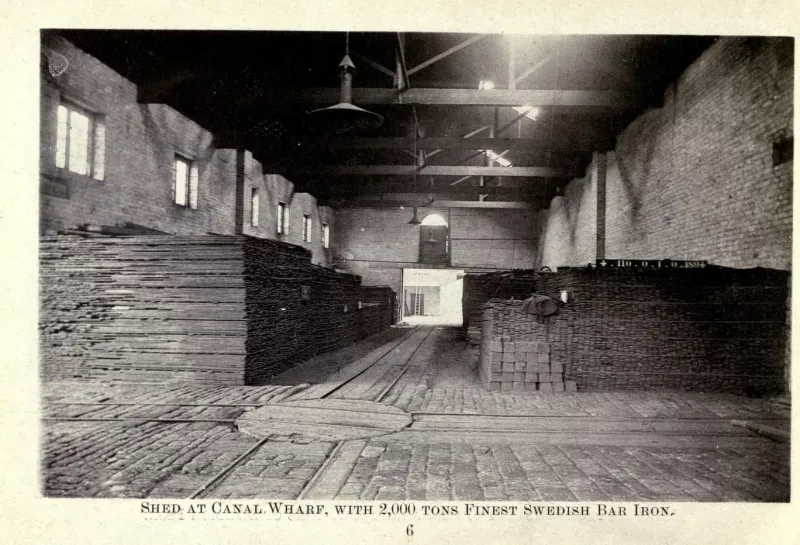

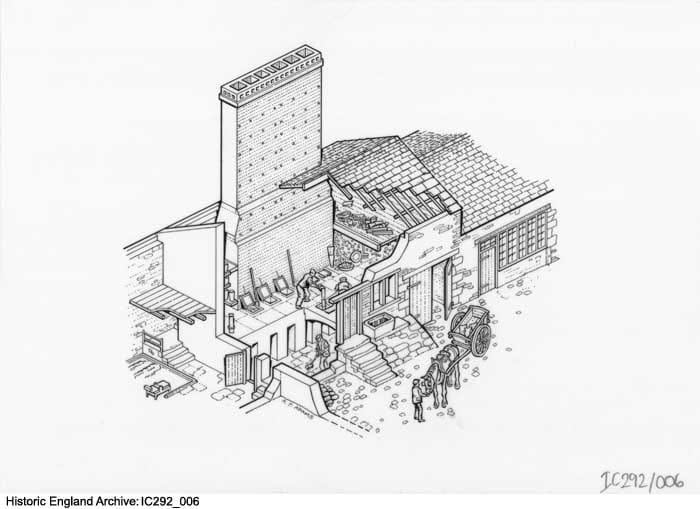

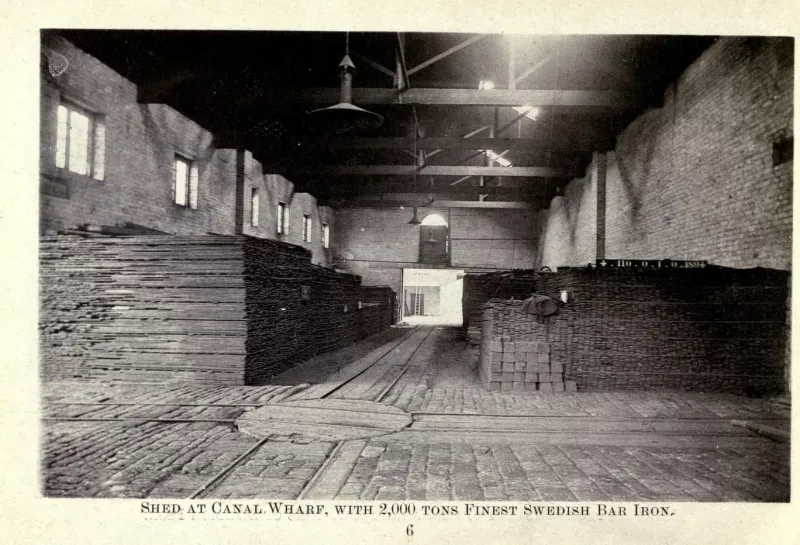

This account from 1905 describes a processes essentially unchanged since its invention over 150 years earlier, and still reliant on Swedish bar iron that had...

Crucible steel was still in demand well into the twentieth century, despite competition from the spectacularly successful (and much cheaper) large-scale production processes introduced by...

iron & steel

cyclops work

cyclops work

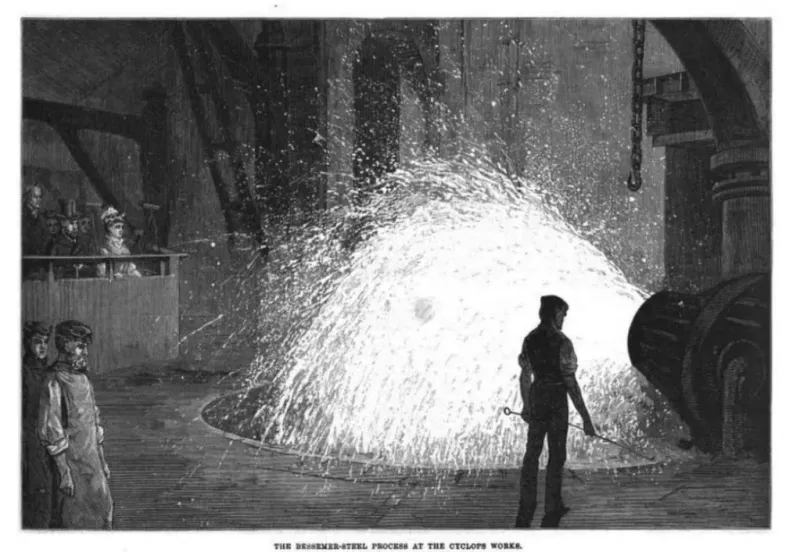

By the 1850s the demand for high quality steel – driven by the rapidly expanding railway, armaments and ship building industries – was beginning to outpace steel production capabilities. Within a decade the newly invented Bessemer process would slash costs and massively increase production, changing the industrialised world forever.

At this time the UK was the largest...

By the 1850s the demand for high quality steel – driven by the rapidly expanding railway, armaments and ship building industries – was beginning to outpace steel...

iron & steel

The crucible steel made in Sheffield maintained a reputation as the best steel in the world for nearly two centuries. This success was built on a combination of skill, quality raw materials and the commercial brilliance of the UK’s manufacturing heartlands of the 18th and 19th centuries.

The principle ingredient of Crucible steel was...

The crucible steel made in Sheffield maintained a reputation as the best steel in the world for nearly two centuries. This success was built on...

iron & steel

Well known UK woodworkers like Paul Sellers and Richard Maguire do a great job of showing how to build a workbench with a minimal set of tools and without an existing bench. I was lucky to have a bench already, but Sellers and Maguire both go through their instructional videos using a couple of sawhorses...

Well known UK woodworkers like Paul Sellers and Richard Maguire do a great job of showing how to build a workbench with a minimal set...

English workbench

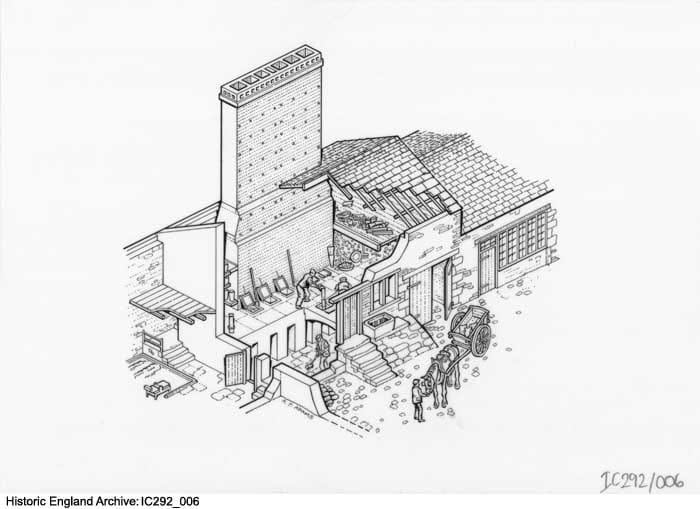

Bar-iron (also known as wrought iron) was the raw ingredient for creating a form of steel known commonly as blister steel, and blister steel was in turn the primary ingredient for the crucible steel used by Sheffield tool makers.

Steel is made by combining iron with small amounts of carbon. The puddling process used to...

Bar-iron (also known as wrought iron) was the raw ingredient for creating a form of steel known commonly as blister steel, and blister steel was...

iron & steel

As discussed in the previous post, plane blades from the 19th century were typically made of a wrought iron backing with a hard steel bit welded to the tip[1].

To better understand the history of these and other edge tools created in this era we can take a look at the processes used to...

As discussed in the previous post, plane blades from the 19th century were typically made of a wrought iron backing with a hard steel bit...

iron & steel

If you pick up a wooden bench plane from the the last century (there are lots of them about still!) the chances are it will have a ‘laminated’ cutting iron (we are going to touch on some basic metallurgy with many mentions of iron in this post, so I will refer to them as ‘blades’...

If you pick up a wooden bench plane from the the last century (there are lots of them about still!) the chances are it will...

bench planes

Makers of edge tools, including plane blades, need to be concerned about several different properties of steel.

Steel Properties

Toughness: This is the ability of the steel to deform without breaking, cracking or chipping. Materials that lack toughness are said to be brittle. Note that sharpening angles have an effect here – the narrower the angle...

Makers of edge tools, including plane blades, need to be concerned about several different properties of steel.

Steel Properties

Toughness: This is the ability of...

bench planes

The bench is finished! I am very pleased with the holdfasts, they were made by Simon James and I got mine from Classic Hand Tools, delivered next day at the very reasonable price of £49 for the pair including delivery.

Some people have trouble using holdfasts on thin tops, I experimented on the front apron...

The bench is finished! I am very pleased with the holdfasts, they were made by Simon James and I got mine from Classic Hand Tools,...

English workbench

Tradition has it that you should either use a 50/50 mix of boiled linseed oil* and turpentine or not bother with a finish at all. I still like to do a bit of tool fiddling now and then – which often involves some grubby metalworking – so I decided to put a finish on mine to...

Tradition has it that you should either use a 50/50 mix of boiled linseed oil* and turpentine or not bother with a finish at...

English workbench

As I mentioned earlier, my brilliant plan of drilling separate holes for the guide rods and screw for the vice was not a success. The holes have to be positioned exactly right and, although I had the holes in the right place, it seems I had not drilled them completely square and the rods were...

As I mentioned earlier, my brilliant plan of drilling separate holes for the guide rods and screw for the vice was not a success. The...

English workbench

I have now flattened the top and rear apron – it took about an hour and forty five minutes (for the rear I just took off the grungy surface but made no effort to flatten it). This is in addition to the time I spent previously removing the high spots on the top and doing the...

I have now flattened the top and rear apron – it took about an hour and forty five minutes (for the rear I just took off...

English workbench

I did the initial flattening of the top in about 40 minutes – I used my wooden jack plane to take off the high points and then the wooden jointer to work across the grain. The result is not pretty but is reasonably flat, and I will clean it up on another day.

The apron took...

I did the initial flattening of the top in about 40 minutes – I used my wooden jack plane to take off the high points and...

English workbench

Today’s update consists entirely of making holes – hole 1 is for the bench stop, hole 2 (more of a trench really) is to accommodate the top of the rear jaws of the vice.

My brilliant plan for the vice is to fit it on the inside of the apron and, so it will sit...

Today’s update consists entirely of making holes – hole 1 is for the bench stop, hole 2 (more of a trench really) is to accommodate...

English workbench