By the 1850s the demand for high quality steel – driven by the rapidly expanding railway, armaments and ship building industries – was beginning to outpace steel production capabilities. Within a decade the newly invented Bessemer process would slash costs and massively increase production, changing the industrialised world forever.

At this time the UK was the largest steel producer in the world, with the majority of the product being made in Sheffield. By the 1850s rapid industrialisation was creating a huge demand for wheels, rails, axels, plates and machine parts that tested the limits of the Sheffield steel industry and the old crucible steel production processes they relied upon. Initial attempts to adapt the crucible steel processes to the new requirements – including the need for the extremely large castings required by the railway and shipbuilding industries – delivered some impressive results nonetheless.

The limits of crucible steel

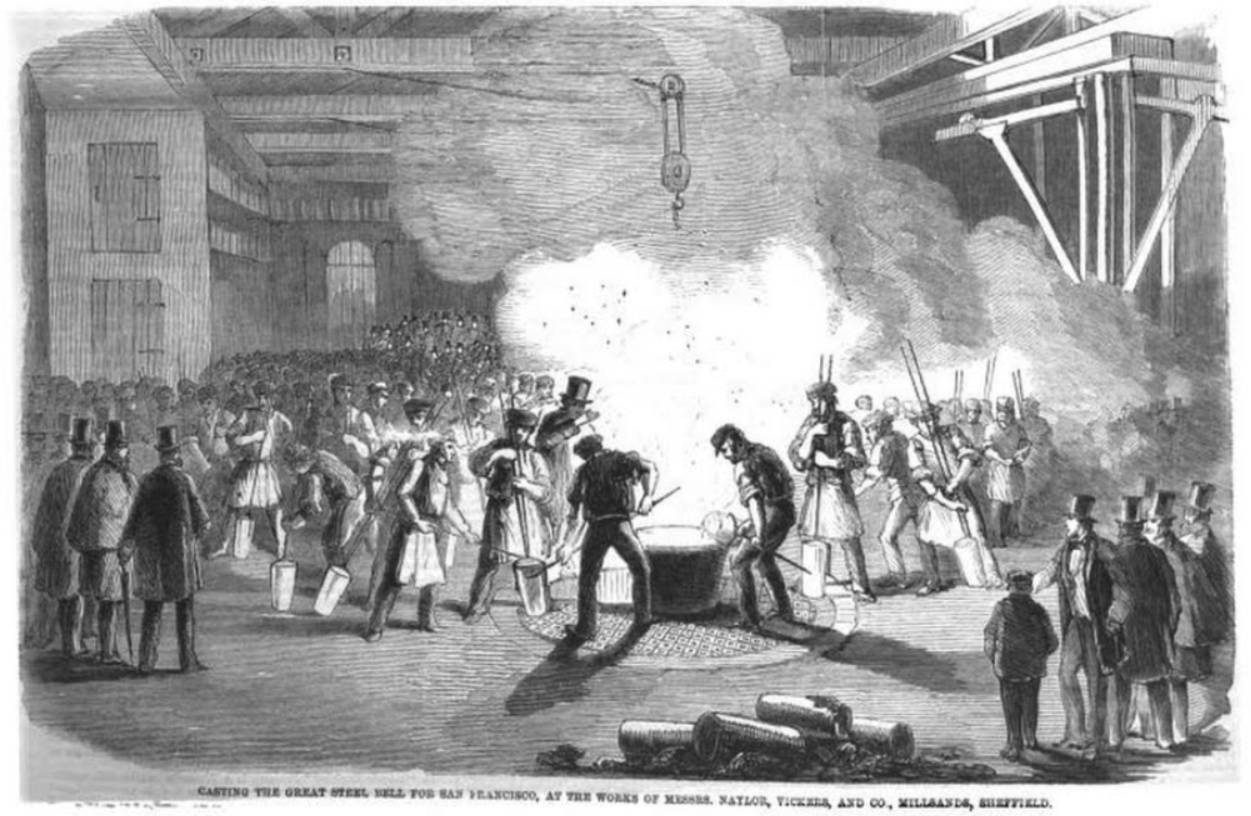

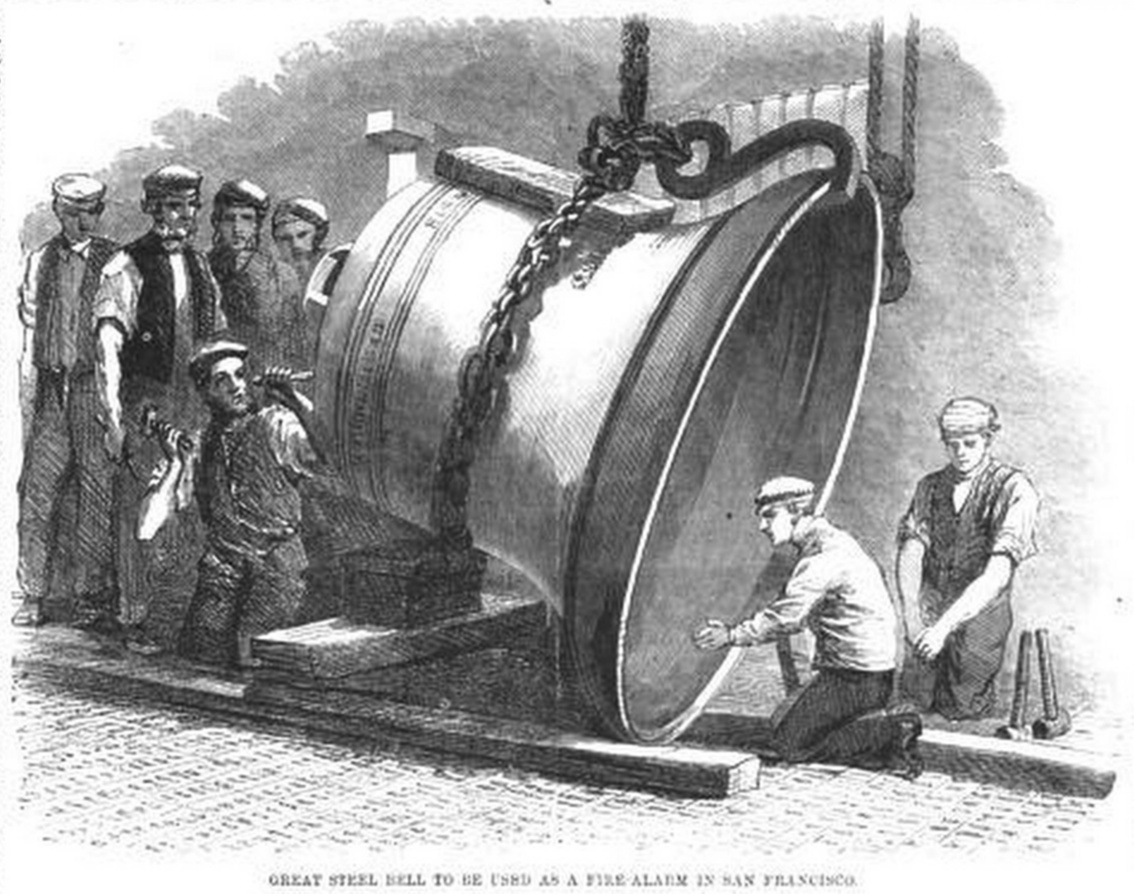

It was difficult to scale up the crucible steel making process so that it could produce very large parts although this did not stop the biggest forges from trying and a couple of famous examples stand out. The first was a steel bell made by Naylor, Vickers and co at their River Don Works, Brightside, Sheffield in 1860. The bell was ordered by the city of San Francisco to act as a fire warning alarm and it was about 5 ft tall, weighing over 2 tons. A casting on this scale was clearly an event of some note and it was attended by the general public and reported in the illustrated London News:

As can be seen in the first etching above, creating large castings required many crucibles to be poured into a reservoir which, once enough steel had been added, was unplugged to allow an uninterrupted flow of molten metal to a mould suspended in a pit below. A Frenchman, Samson Jordan, visiting the River Don works a few years later in 1867 reported in the Métallurgie du fer et de l’acier (Metallurgy of iron and steel) that Vickers were by then able to make casting weighing 20,000kg (over seven times the weight of the San Fransisco bell) which required around 500 crucibles to be poured in succession.

At this time Vickers had 288 melting holes[1] each of which could take two crucibles, and a casting of this size would have needed nearly all of them to be heated simultaneously.

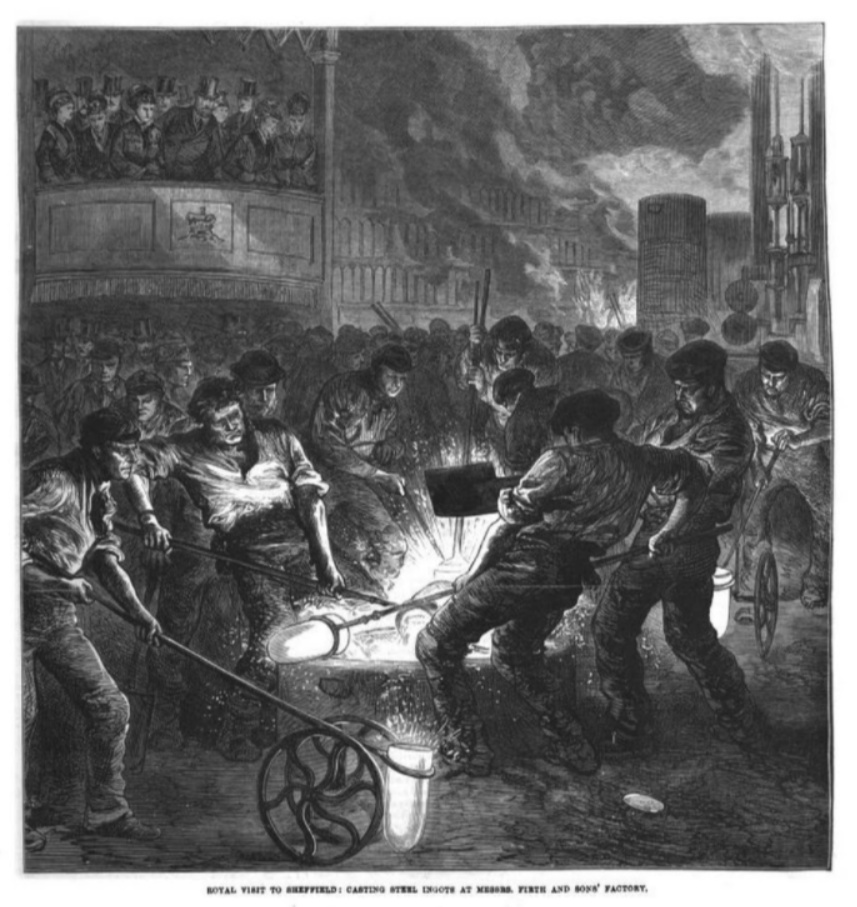

Castings of this immense size were exceptional however, and remained newsworthy even a decade later. A royal visit to Firths was reported in August 1875:

” The second day was chiefly occupied with the inspection of the famous Sheffield manufactures of iron and steel. The Prince and Princess were accompanied by the Duke of Norfolk and the Ladies Howard Earl and Countess Fitzwilliam and their family, Lord and Lady Wharmcliffe, Lord and Lady John Manners, Lord Auckland the Earl and Countess of Galway and other ladies and gentlemen of rank.

The Norfolk Works belonging to the firm of Messrs Thomas Firth and Sons of which the Mayor is the head, were the first visited by the Prince and Princess. Here they saw the old process of melting which yields from the Swedish iron the finest steel. The rows of clay crucibles at once attracted their notice. Each crucible lasts only three castings so that the consumption of these vessels is incessant and they are made by wholesale in these works, the material used being a mixture of pot clay and china clay. The crucibles are in holes in the floor which seems honeycombed for the purpose In vaults below the fire is kindled, the crucible is covered with hard coke and left till its contents are melted. The dexterous workmen drag it from its cavity by tongs and pour the contents into iron moulds These are of different sizes and vary from one ton up to sixteen or even eighteen tons the largest steel ingot ever cast.

There are 400 of these melting holes in which the tools the steel must be of a different quality and temper a result secured by a certain mixture of the molten steel.

The Illustrated London News, August 25 1875

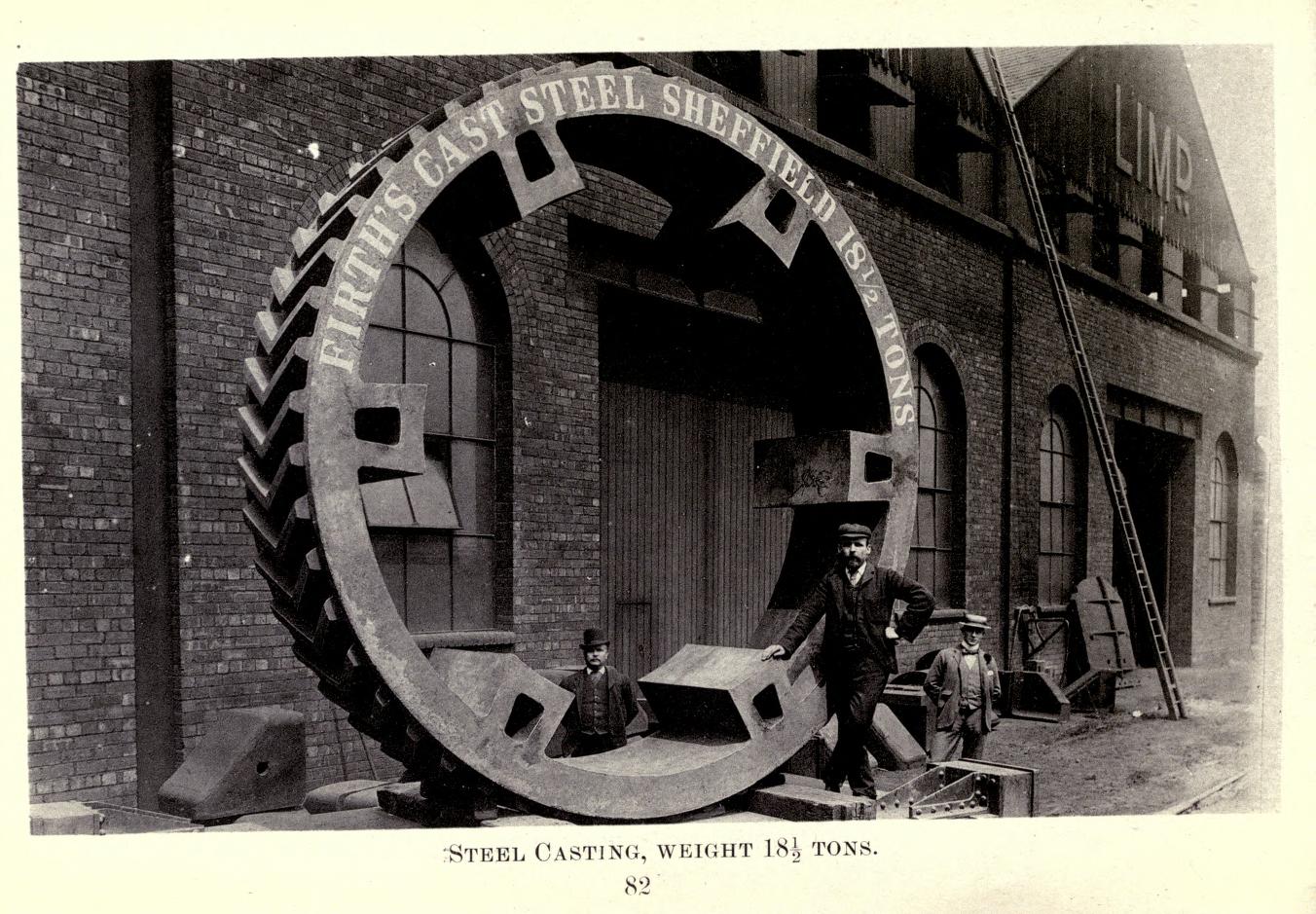

Possibly the largest crucible steel casting ever made – again by Firth’s – was reported in 1874 and required an extraordinary 628 crucibles:

NOTES FROM SOUTH YORKSHIRE

Sheffield, Wednesday. The Woolwich 81 ton Gun

Messrs Thomas Firth Sons of the Norfolk Works Sheffield are now proceeding with the production of the crucible steel ingot required for the 81 ton gun which is about to be built at Woolwich. This ingot will be used for the internal tube which lines the gun.

The rough casting was made at Messrs Firth’s works Friday last and is in all probability one of the largest castings ever made. In its production 628 crucibles, each containing 70 lb of steel were used, making the total weight about 20 tons. One hundred and ninety four men were engaged in the work which occupied about forty minutes.

The ingot is 42 in in diameter and 13 ft in length

Engineering May 1st 1874

High Costs

Despite these impressive achievements, the process to make large crucible steel castings was unwieldily and extremely lengthy. To recap:

- The process began with the mining and smelting of iron ore in Sweden.

- The iron was then “puddled” and rolled into bars of wrought iron.

- Once shipped to Sheffield these bars were carbonised in a cementation furnace that had to be continually heated for 10-14 days,

- The furnace took another 1 or 2 weeks to cool down to a point where the resulting ‘blister steel‘ could be safely removed.

- Finally, the best part of a day was needed to melt and teem the steel. As noted above, this stage in particular required a lot of manpower.

In addition to taking many weeks to complete, the equipment needed occupied many large buildings and consumed huge amounts of fuel at each stage. As a result it was simply impractical to rely on crucible steel to meet the burgeoning demand for large steel parts in the long term: a better way was needed.

Enter Bessemer

Henry Bessemer had no connection to the iron or steel trade but he was a prolific inventor and convinced that a fresh perspective, unhindered by worries about details of the existing day-to-day steel-making processes, might make possible the change needed to meet the growing demand for steel.

In the early 1850s he set about studying metallurgy and, after months of consultation and experimentation, set on the possibility of decarbonising cast iron by blowing air into the molten metal. His early experiments were encouraging and in 1856 he applied for a patent to cover his new invention and announced it in a paper – Manufacture of Malleable Iron and Steel Without Fuel – read to the British Association in Cheltnham on August the 11th 1856[2]. At this time, the chemical analysis of steel was still a new science, but Bessemer had gleaned that when pig iron, which typically contained around 5% carbon, was heated to a white heat – as it was when wrought iron was made – the carbon in the metal would combine with oxygen in the atmosphere and boil of as a gas. His great insight was that if he blew air, and thus oxygen, through the molten metal then the carbon and oxygen would have more opportunities to come into contact and the reaction would accelerate.

Early experiments, 1855

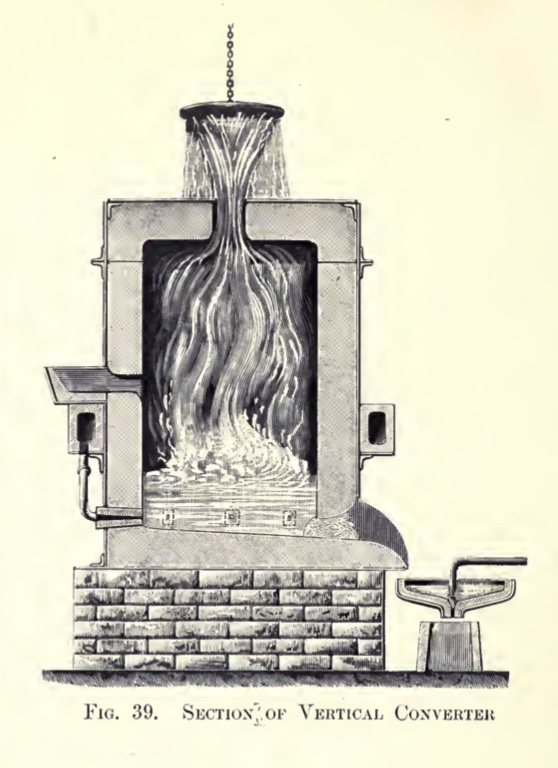

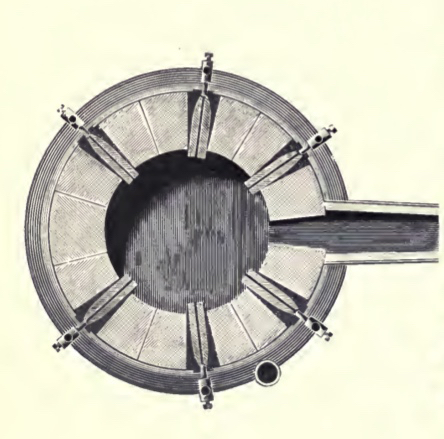

His provisional solution was to create a simple cylindrical converter about 4 ft. in height in the interior with a hole in the top to allow any sparks and heated gases to escape from as the air was blown into the molten cast iron. The converter had six horizontal tuyeres (nozzles) arranged around the lower part of it that were supplied by the air blown into the rectangular chamber extending around the converter:

Bessemer reports the dramatic first experiment in his autobiography:

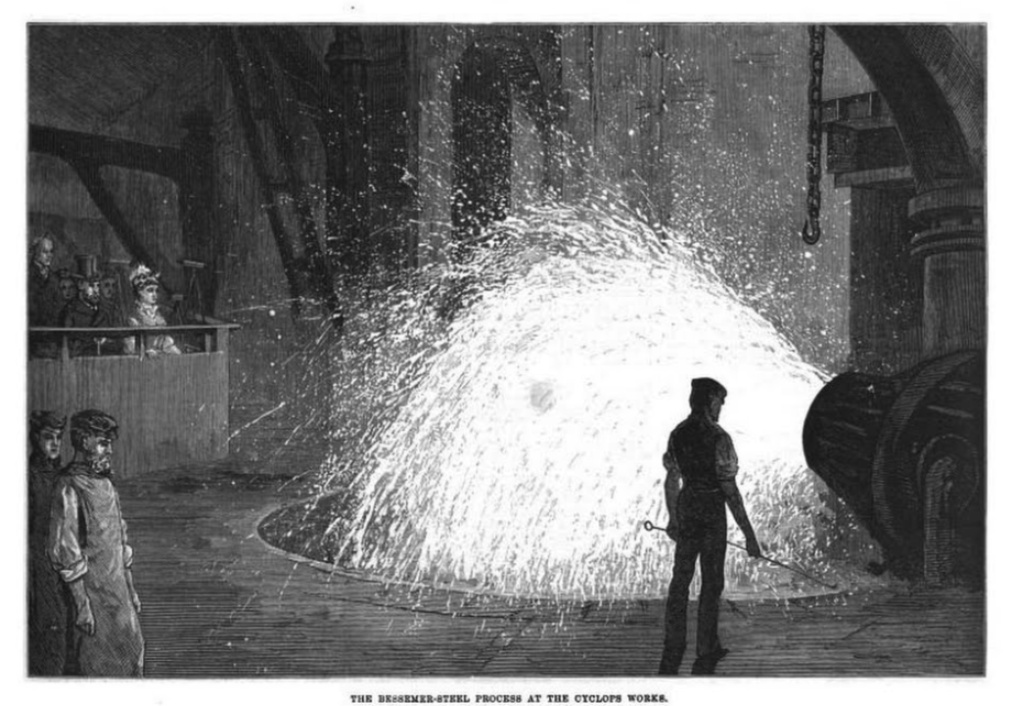

All went on quietly for about ten minutes ; sparks such as are commonly seen when tapping a cupola, accompanied by hot gases, ascended through the opening on the top of the converter, just as I supposed would be the case. But soon after a rapid change took place ; in fact, the silicon had been quietly consumed, and the oxygen, next uniting with the carbon, sent up an ever-increasing stream of sparks and a voluminous white flame. Then followed a succession of mild explosions, throwing molten slags and splashes of metal high up into the air, the apparatus becoming a veritable volcano in a state of active eruption. No one could approach the converter to turn off the blast, and some low, flat, zinc-covered roofs, close at hand were in danger of being set on fire by the shower of red-hot matter falling on them. Sir Henry Bessemer, F.R.S. : an autobiography (1905)

For the second attempt he suspended a steel plate about a foot in diameter (shown in the diagram above) above the furnace to try and contain the eruption of sparks but it immediately melted in the inferno. The experiment had shown great promise, having successfully converted pig iron into a malleable iron in the space of a few minutes – work that would have taken several skilled ‘puddlers’ of wrought iron hours to replicate – but clearly the apparatus was too dangerous to be used commercially in its current form.

At this point in the development of steel there was no firm agreement on the chemical difference between iron and steel, but today we would say that Bessemer had succeeded in creating a purified form of iron, since his process was very effective at removing the carbon from the melted pig iron and, by doing, so he imparted the metal with some of the malleability and toughness of wrought iron, which is also a low carbon form of iron, having been decarbonised in a puddling furnace.

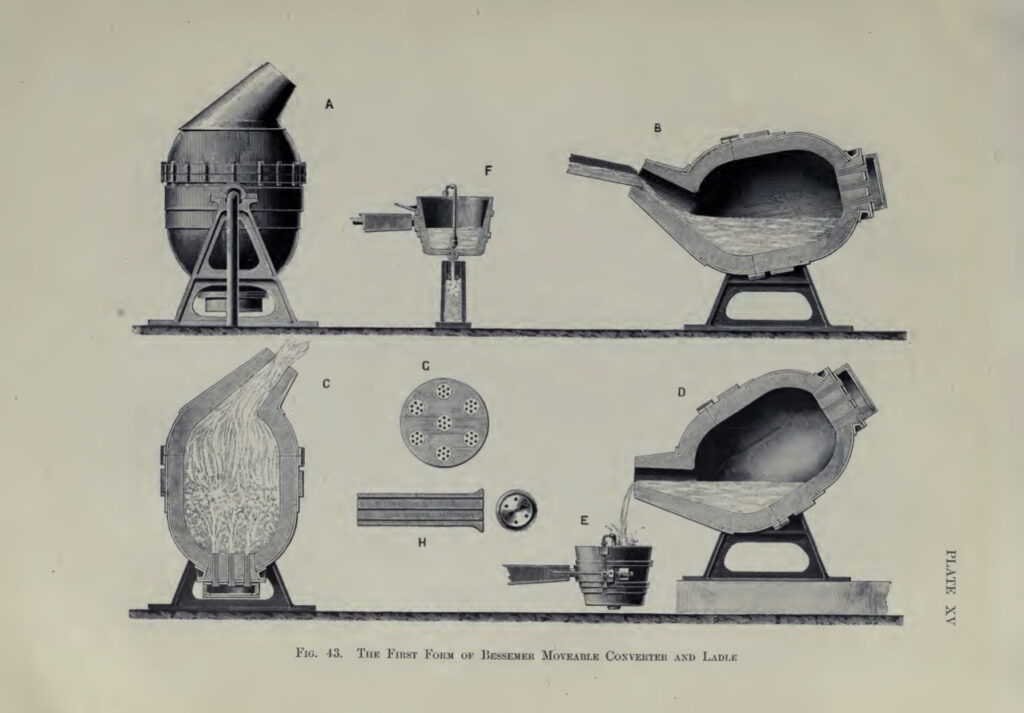

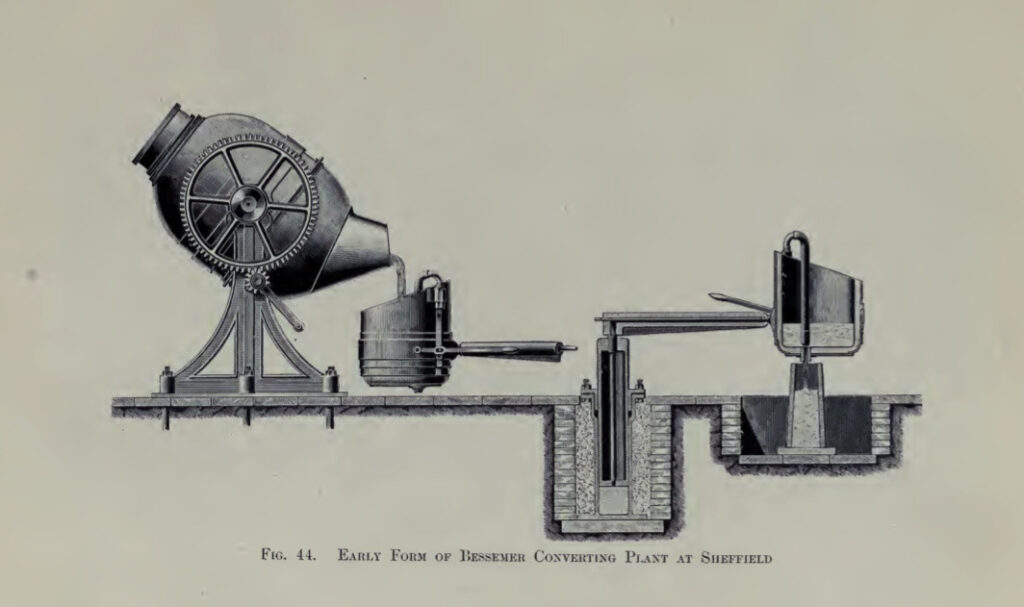

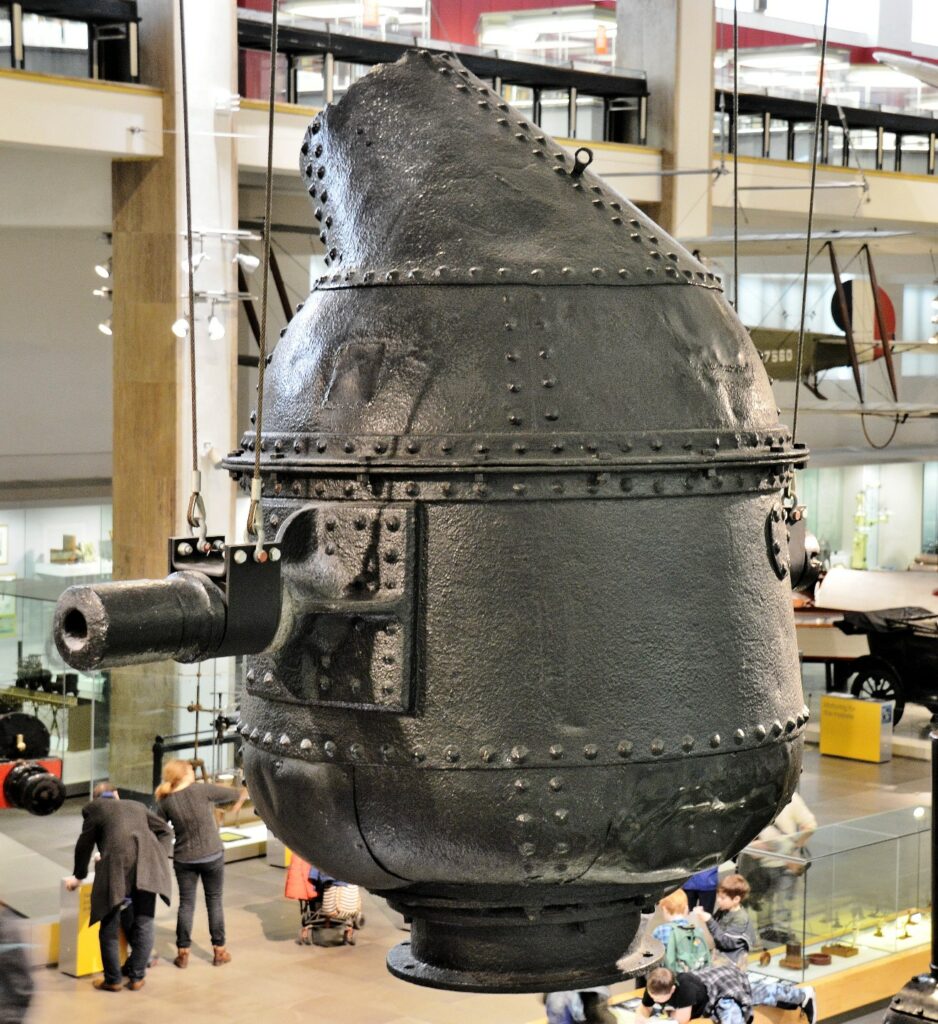

Bessemer was soon able to resolve the technical problems with his "Converter", not least of which was that, because compressed air had to be continuously blown into the convertor to stop molten metal flowing back through the nozzles, the dangerous conversion process was impossible to stop once it started. Eventually the idea occurred to him of mounting the converter on axes, so as to be able to keep the tuyeres above the metal until the charge of molten iron was run in, thus permitting the process to be stopped by tipping the vessel. This critical development allowed him to control the degree of decarbonisation so that he could create steel of varying tempers.

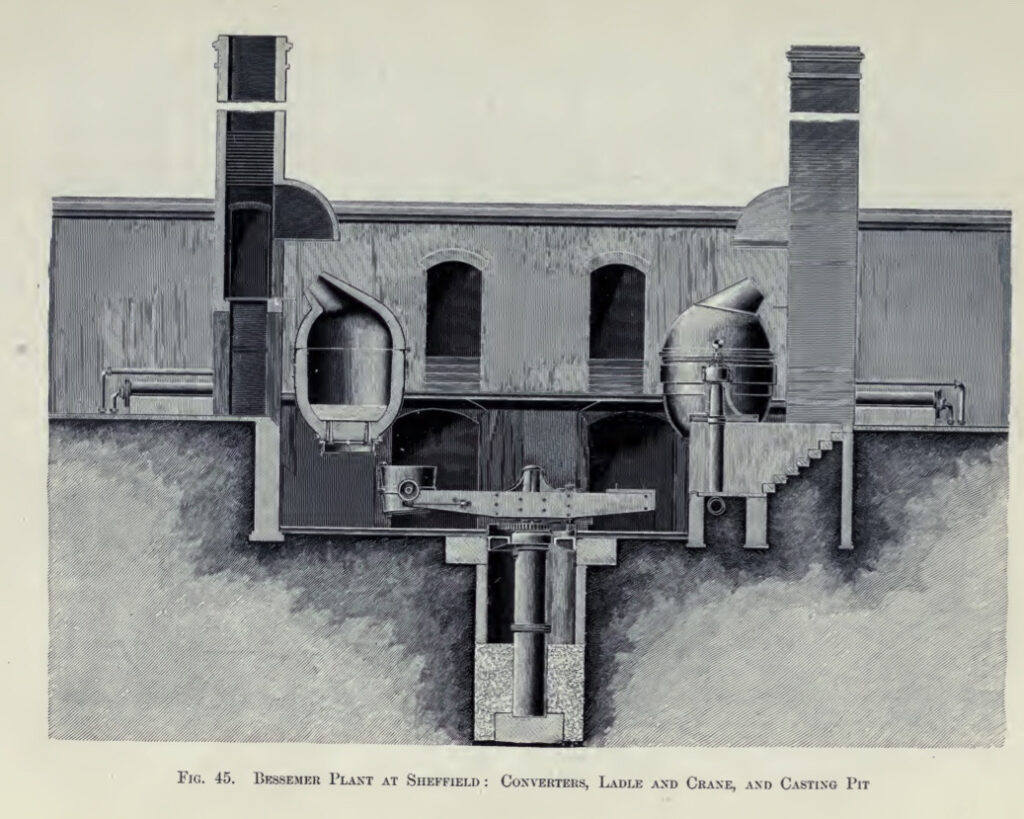

The first movable converter was installed in his works at Sheffield:

This was an important step forward, making possible the rapid creation of larger volumes of steel compared to the previous technology, but even so he faced great difficulties getting the technology accepted.

Initial Difficulties

The incumbent steelmakers, whose success had been built on techniques that had barely changed for over a hundred years, were inevitably sceptical that this outsider might have invented a process that could do all he claimed, but Bessemer was able to convince a small number of them to license his patent. Unfortunately the initial attempts by these businesses to repeat Bessemer’s experiment were disappointing, creating metal that was either brittle when cold or when hot, or both. With no one – including Bessemer – able to explain the failures, optimism for the prospects of the new technology quickly turned to despondency.

Bessemer eventually discovered that the poor results were caused by the type of pig iron being used in the later experiments. This had been sourced locally, and cheaply, but was high in phosphorus, an impurity that had been absent in the Swedish pig iron Bessemer had used in the original experiment. Happily his investigations coincided with the time when Swedish government lifted the ban on the export on their pig iron – which was naturally very low in phosphorus – and he was able to prove the point by repeating his demonstrations using this cleaner raw material.

Although this step forward was important in confirming the new process was viable, it was still expensive to acquire low phosphorous pig iron and Bessemer needed to find a way to make it work with cheaper raw materials in order to meet his initial boast about the potential cost savings his product would yield.

Robert Mushet

He continued to experiment with local pig iron, including the use of additives like manganese that, when added to the molten metal reacted with the phosphorus and other impurities causing them to be expelled as slag. Another inventor, Robert Mushet, claimed to have patented this process although Bessemer argued the use of manganese had been well known before the patent was granted and refused to pay Mushet a royalty.

In December, 1866, Mushet’s daughter paid him a visit and explained that they had fallen on hard times and that without finacial help they would loose their home and saying to Bessemer that “They tell me you use my father’s invention, and are indebted to him for your success.” Although Bessemer continued to deny infringing Mushet’s rights he agreed to provide financial help and later on offered Mushet a small annual pension.

Bessemer was eventually able to source a supply of low phosphorous iron ore from Cumbria, and he partnered with the Workington Iron Company to set up convertors there. These converters ran until the 1970s and a rare film of the process in operation was made in the late 1950s:

The problem of phosphorous contamination was finally solved once and for all two decades later when Thomas Gilchrist discovered that a lining made of dolomite applied to the inside of the convertor would remove the phosphorus in local mined iron melted by coke fires allowing this cheap pig iron to be used as a raw material for good quality steel.

The creation of a cheaper alternative to wrought iron was a critical step forwards but Bessemer had a bigger goal – he wanted to produce inexpensive steel.

Bessemer persisted, no doubt encouraged by the enormous size of the opportunity ahead of him: the average price of steel in Sheffield at the time was £60 per ton, but he could buy Swedish pig iron for £7 a ton and, if he could find away from making steel from this raw material with a 20 minute ‘blow’ in his convertor, then the rewards would be enormous[3].

After years of further experimentation, and continued intellectual property controversy, he eventually settled upon a combination of iron, carbon and manganese that, when added to his ‘converter’, imparted sufficient carbon to make a mild steel with the properties of elasticity and toughness that were advantageous in the making of plates for ships, forgings, ordnance, rail tracks and the like.

Four years had elapsed since his first announcement and, needless to say, he had an uphill battle to convince the public that a process previously condemned as a failure by all and sundry was now working reliably. Such was the reluctance to take him seriously that even the handful of companies who had licensed his original patent refused to pursue the work any further[4].

New production facilities, 1861

In desperation, Bessemer bought back the licenses and acquired land in Sheffield so he could begin making steel himself. Over the next couple of years he released his new steel to the market at a significant discount to the products of the other steelmakers and gradually began to build a reputation for his invention.

in 1861 he persuaded the London and North Western Railway to try his steel rails instead of the wrought iron they had been using previously. The tests were a great success, with the steel rails lasting many time longer than the wrought iron equivalents and thus Bessemer at a stroke had created a huge opportunity (there were 25k miles of wrought iron rails that needed replacing).

By 1863 Bessemer was targeting the next largest consumer of wrought iron and steel after the railways: the ship builders, and the first Bessemer steel ship set sail in 1864. In the midst of the developments in shipping and railways, large makers of ordnance and boilers also started to use the new steel.

Before long it was difficult for the traditional steel makers to ignore Bessemer’s success, and they began to license his technology. Bessemer, clearly a canny businessman, was delighted to do so on condition they paid him a royalty of £2 for every ton of Bessemer steel they produced.

Extraordinary success, 1865

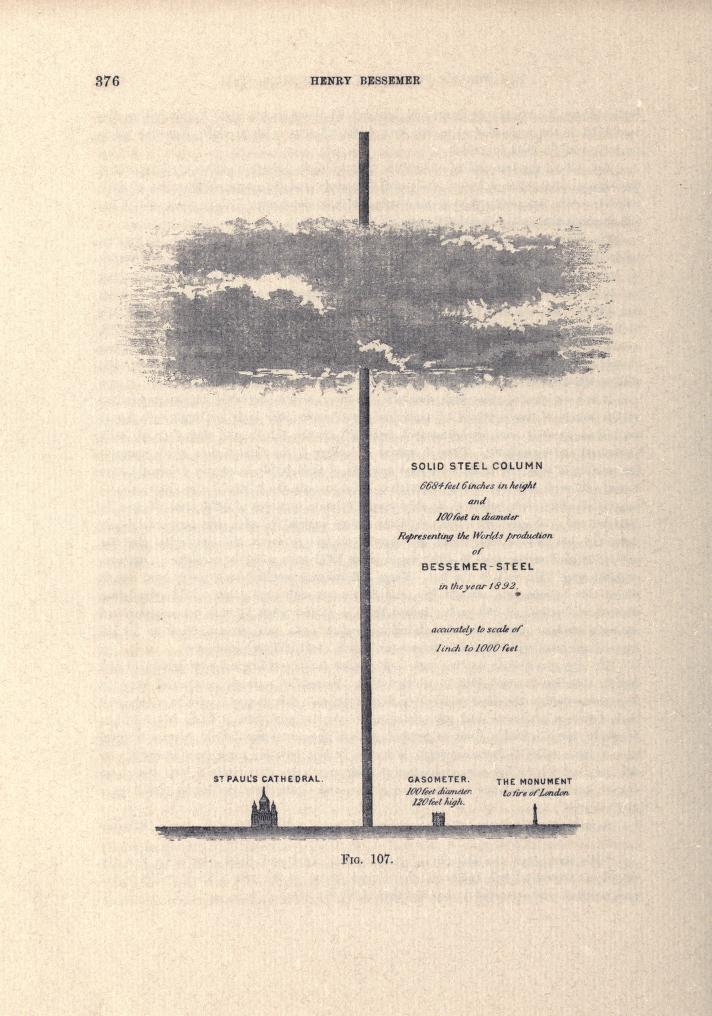

By 1865s there were 17 bessemer steel works, producing 1200 tons per week. From this point onwards adoption of Bessemer’s invention skyrocketed, the scale of which is captured nicely in this illustration:

This was to prove to be the high point for Bessemer steel, with competing technologies for large-scale steel production invented by Siemens coming to Sheffield before the turn of the century, but he had succeeded in almost entirely removing the needed for large scale production of crucible steel.

However, despite the huge success of this much cheaper alternative, the crucible process continued to dominate the market for the steel used in edge tools and, surprisingly, demand in other areas actually increased during the latter half of the century. Henry Seebohm in a controversial paper presented to the Iron and Steel Institute of Great Britain in 1884 offers a robust explanation for this surprising situation:

The accumulated experience of a century has convinced the manufacturers of crucible cast steel that the finest qualities can only be made from bar steel which has been converted from iron made from Dannemora ore. This iron is expensive, its average cost for the last forty years has been at least £25 a ton, the process of converting it into steel is slow and costly the process of melting in small crucibles is extravagant both in labor and fuel and subsequently the best qualities of crucible cast steel can only be sold at a high price.

So called best crucible cast steel is sold at low prices by unscrupulous manufacturers and bought by credulous consumers but though it is quite possible for high priced steel to be bad it is absolutely impossible that low priced steel can be good. The finest quantity of steel cannot be made of cheap material or by a cheap process. Every year the attempt is made and every year it signally fails. No one ever made a better try than Sir Henry Bessemer but his failure was as complete as that of his predecessors. He attempted to produce an article at £6 a ton to compete with one at £60 a ton and failed absolutely. It is true that his steel was a success perhaps the most brilliant success of the century.

I am not quite sure that he himself believes in his failure. In his lecture before the Cutlers company of London in 1880 he chaffed the steel manufacturers of Sheffield on their antiquated attachment to the rule of thumb and twitted them with the assertion that the high price of crucible cast steel arose from a combination of trade interest on their part and of prejudice on the part of their customers. Sir Henry Bessemer may have half ruined the wrought iron trade and revolutionised the pig iron trade but the crucible cast steel trade holds its own in spite of his great discoveries. When railways were first introduced and waggons and coaches to a large extent driven off the road many people thought that the price of horses would permanently fall but exactly the contrary took place. Similar fears were entertained that the demand for crucible cast steel would seriously decline when Bessemer and Siemens steel came into the market. This has not been the case. The commoner qualities of crucible cast steel have been to a large extent suppressed by Bessemer’s and Siemens steel but the enormous quantities made by the latter processes have required for their manipulation directly or indirectly such a large quantity of the better qualities of crucible cast steel that the total amount of the latter now produced in various parts of the world is probably double that which was required before the birth of its rivals steel iron.

Henry Seebohm. The Engineer, Volume 58, September 26 1884

During the subsequent lively discussion Bessemer provided a stout defence arguing again that it was the traditional steel makers resistance to change that hindered adoption of his steel for requirements like tool making but, despite his protestations, it was apparent that Sheffield makers had experimented with his metal and simply got better results from crucible steel[6]. For example Jessops and son report that they had experimented with melting bessemer iron in their crucibles but found it was ‘a false economy’ compared with Swedish bar (see The engineering and Mining journal).

It is hard not to sympathise with Bessemer, fighting as he was with an entrenched industry, but it is also clear that crucible steel was genuinely superior for certain applications, including edge-tools. The debate about why this was so was not satisfactorily resolved in Bessemer’s lifetime, largely because at the time chemists lacked the tools to accurately analyse all aspects of the two metals and were forced to resorting instead to vague terms like ‘body’ which went some way to explain the prejudices of the traditional steelmakers but did little to advance the understanding.

Thus the 150 year old crucible steel lived on, and as we shall see, it lived on for a surprisingly long time.

References

| 1⏎ | Engineer, Oct 25th 1867 |

| 2⏎ | the paper was also published in The Times a few days later as reported in The creators of the age of steel |

| 3⏎ | op cit p55 |

| 4⏎ | op cit p66 |

| 5⏎ | for example Jessops and son report that they had experimented with melting bessemer iron in their crucibles but found it was ‘a false economy’ compared with Swedish bar: The engineering and Mining journal |

| 6⏎ | for example Jessops and son report that they had experimented with melting bessemer iron in their crucibles but found it was ‘a false economy’ compared with Swedish bar: The engineering and Mining journal |

| 7⏎ | Copyright Dave Hudson and licensed for reuse under this Creative Commons License |