As I mentioned earlier, my brilliant plan of drilling separate holes for the guide rods and screw for the vice was not a success. The holes have to be positioned exactly right and, although I had the holes in the right place, it seems I had not drilled them completely square and the rods were binding on the walls of the holes. I wasted some time trying to adjust the undercarriage position (turn bench over, remove all the screws, reposition, find it flip bench, find it did not work etc) before concluding the only way to do fix it was to gouge out the edges of my previously perfectly neat holes.

Several bench flips later and I go it to work properly. Matters were made worse when it turned out some buffoon (me) and removed my ratchet-spanner and hidden it in the boot of the car, only for it to be rediscovered a day after it was needed. Thus I turned a 30 minute job into 3 hours of fannying around – if I were doing it again I would just cut out a large single mortice (with plenty of wriggle room) to allow all the components through the apron.

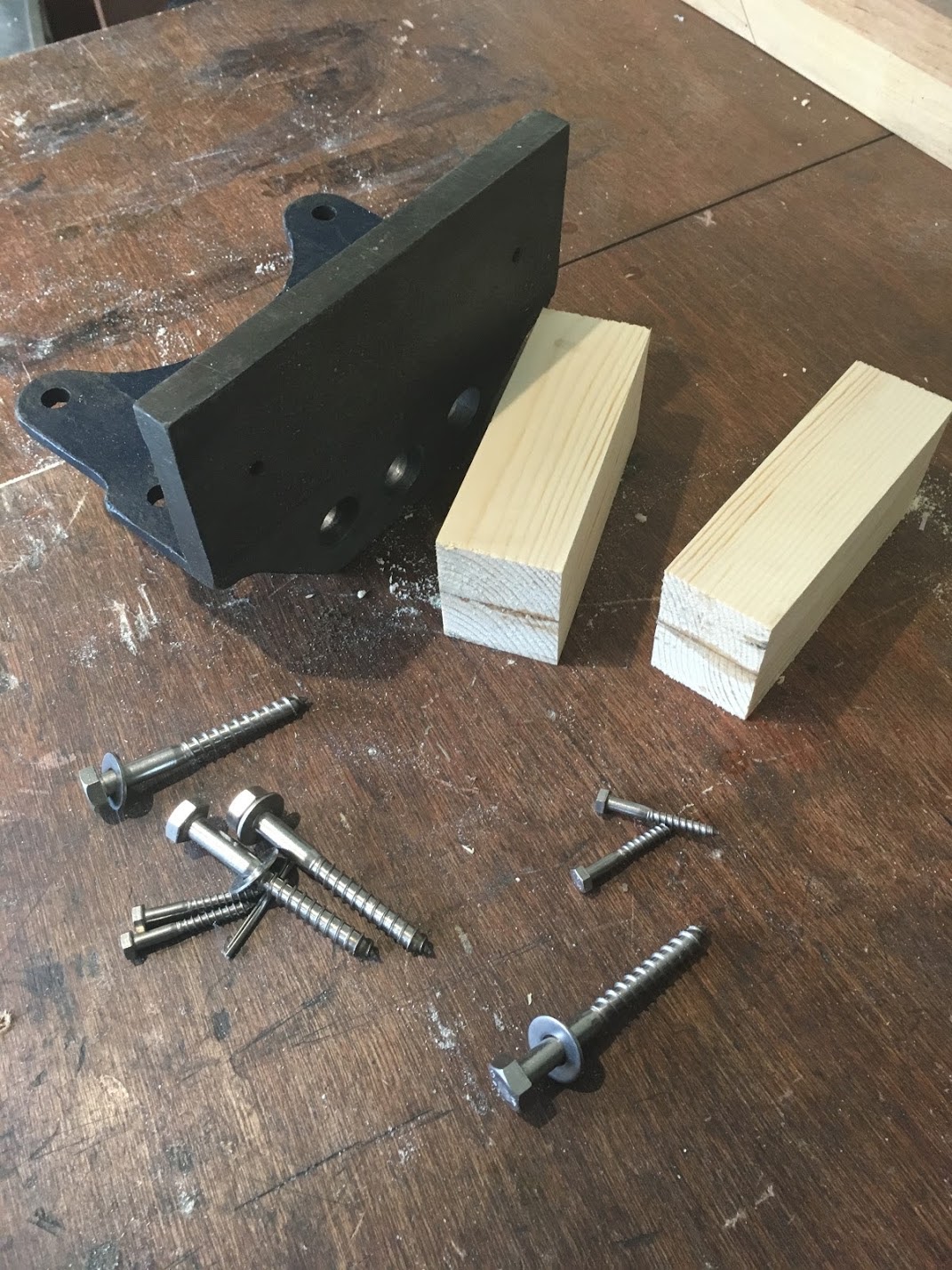

Not a lot to say about fixing the vice – you need to make up a wooden spacer or two and then you can either bolt it through the top or use coach screws from underneath

spacers and coach screws/ Millers Falls drill – excellent and still relatively easily to get hold of (straightforward to refurbish too).

I used 70mm M10 coach screws for the undercarriage and M6s for the jaw cheek*.

The wooden insert on the front jaw is a maple and salvaged from the vice on my old bench.

I also made the bench stop – not a lot to say really, you just plane it a fraction bigger than the mortice and then take a few savings off until it is a tight fit. Apparently it is possible to split the top along the long grain if you make that dimension too tight, so be careful.

I may have to replace it with harder wood in the future (i used a bit of old fence post, which is all I had).

* for those after doing a proper job, the face jaw of old Record vices have a screw threaded hole (5/16” BSW)

bench stop/ Record 52 1/2 Vice