Once you have the engine back together an important job is to adjust the valve clearance (sometimes called “valve lash”). The clearance you are adjusting is the gap between the “tappet” and the tip of the valve. Tappet is an Engineering term meaning:

a moving part in a machine which transmits motion in a straight line between a cam and another part

In this case the c90 the tappet is formed by a rocker arm with an adjustment screw on one end and a hardened metal slipper foot on the other. The foot of the rocker arm follows the profile of the cam and the grub screw contacts the tip of the valve, transferring the motion of the cam shaft to open and close the valve.

The idea is to adjust the clearance using the tappet adjustment screw so that – when the engine is running at operating temperature – the tappets and cams are positioned at the correct distance determined by the Honda engineers. If the gap is either too big or too small then problems can ensue. Note that the adjustment to set the correct gap must be done when the engine is cold, for reasons that will become clear later.

valve gaps too large

I am a bit hazy on the physics of the “gap too big” problem, but it seems to come down to the difference between pushing something and striking it. The cams on the camshaft are shaped like a ramp and are designed so that the momentum of the tappet increases gradually until the valve is fully opened.

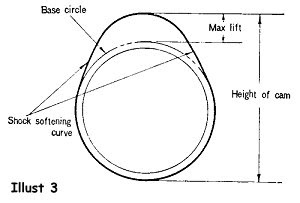

As can be seen in diagram of a cam profile below, the cam is designed so that the face of the rocker arm initially contacts the shallower part of the cam. This is intended to smooth the acceleration of the part, allowing any play in the cam and valve mechanism to be gradually taken up and reducing the impact. When the valve clearance is too large this part of the ramp is bypassed and instead the follower contacts the harsher part of the ramp and is accelerated more aggressively. The extra momentum gained causes the tappet to strike the valve, a bit like a hammer hitting a nail, and this results in the clattering noise that can be heard when the clearance gap is wrong.

the correct clearance gap ensures the face of the rocker engages with the cam at the point where shock to the parts is minimised

The other effect of valve gaps being too large is on the power the engine generates. This is because the gap has an effect on valve timing: increasing clearance between tappet and valve effectively reduces the time the valve is open, and this interferes with the draw of fuel/air mixture into the engine.

… and gaps too small

What happens when valve gaps are set too tight? In extreme cases the tappets can be over tightened to the extent that the valves are kept open all the time and never properly seal the cylinder.

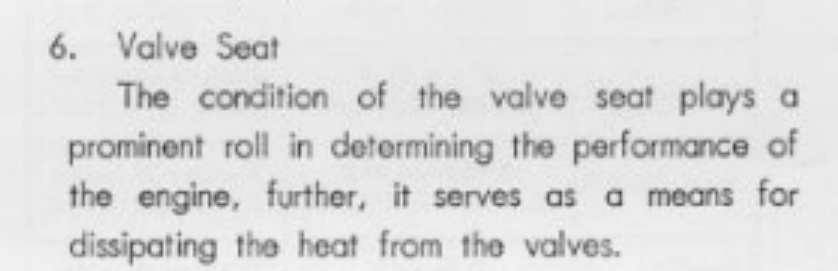

Problems can still occur when the gap is sufficient to allow the valves to close properly but are tighter than the amount specified by the manufacturer. This is because the contact between the valve and valve seat is what allows heat from the valves to transfer to the air-cooled cylinder head:

extract from a 1960s Honda workshop manual

A too narrow gap causes the valves to open sooner and close later, meaning they are in contact with the head for a shorter period and this reduces the time for heat dissipation. If the valves get too hot they can ‘burn’.

This tends to happen on the exhaust valve which, unlike the intake, is not cooled by air drawn from the carburettor, and therefore gets correspondingly hotter.

If overheated valves are burned this can damage the seating surfaces and – since hot gasses cab now leak past the damaged areas – this makes the problem worse. Here are some burned exhaust valves showing the damage that can occur:

The two burned valves on the left are from a V12 Jag

Valve gaps at operating temperature

Since the metal components in an engine expand with heat, the valve gap at operating temperature is different from the valve gap when the engine is cold. The amount the valve gap grows or shrinks is determined by the materials of the components involved in operating the valves:

The rocker arms are housed in the aluminium head which, as it gets hot, tends to move the rocker arm away from the valve, but at the same time the valve gets longer as it heats up, offsetting the effect.

The other factor in determining the relative expansion rate of the parts is the degree they are heated by the combustion process: although the aluminium cylinder head should expand more than the steel valves, the equation is altered by because the steel valves get very hot compared to the cylinder head which is cooled by the air that flows around it.

This is why it important to set the gap when the engine is cold - if you don't the effect caused by the expansion of the parts will mean you do not get an accurate measurement.

How much clearance is needed?

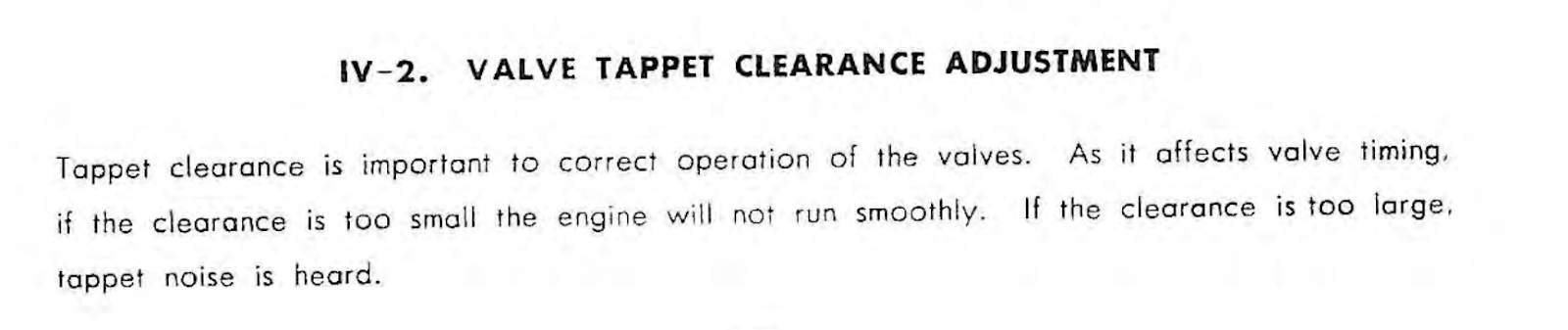

In addition to minimising engine wear and tear, Honda also had to worry about performance. As we saw earlier, the clearance gap changes the valve timing (by delaying or advancing the point when the valve open or close) and this impacts the flow of fuel and air which in turn affects how engine runs.

These consideration are summed up in this entry in a 1960s factory workshop for an older bike (the ca95):

The clearance needs to be regularly adjusted to compensate for wear on the parts (as the valve seats wear, the valves tend to sit higher in the cylinder head and this reduces the gap between tappet and valve end).

Honda specify that the valve gap for the 1978 C90 z2 should be set to 0.05 mm and recommend this is checked every 3000 miles.

Since Honda caused upheaval in the motorcycle market during the 60s and 70s based largely on their success creating low maintenance engines, you might wonder why – if it is true that the gaps tend to reduce over time, and given the serious consequences when gaps are too narrow – they did not allow a larger gap and then extend the maintenance interval? The clue to the answer is probably in the snippet above: a wider gap creates more engine noise which might be cause for complaints to the Honda dealers.

You can read about adjusting the valve clearance gap here.