It hardly needs saying but the engine only works when air gets in one end and exhaust gasses exit the other. This article covers the two systems on either end of the engine, the air cleaner and the exhaust.

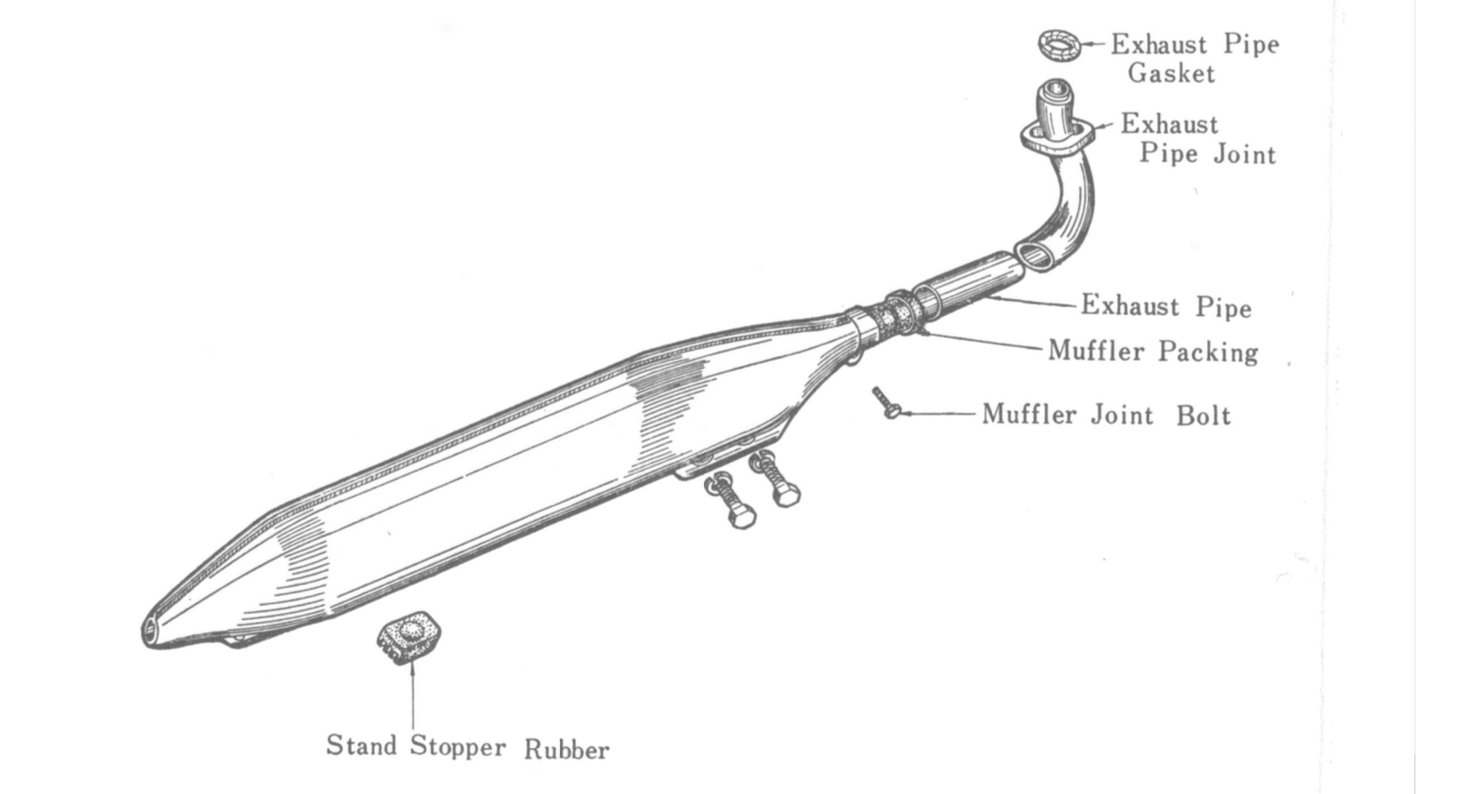

Muffler and exhaust pipe

Although in the UK we tend to refer generically to "exhaust systems", strictly speaking there are two separate components, the muffler (or silencer as we would say in the UK) and the exhaust pipe (which is the bit that takes the exhaust gases from the engine). In the original Super Cubs these were supplied as two separate parts, joined by a section of rubber packing, but in the early 1960s Honda decided to create a single welded unit as part of their attempts to reduce the engine noise of the bikes.

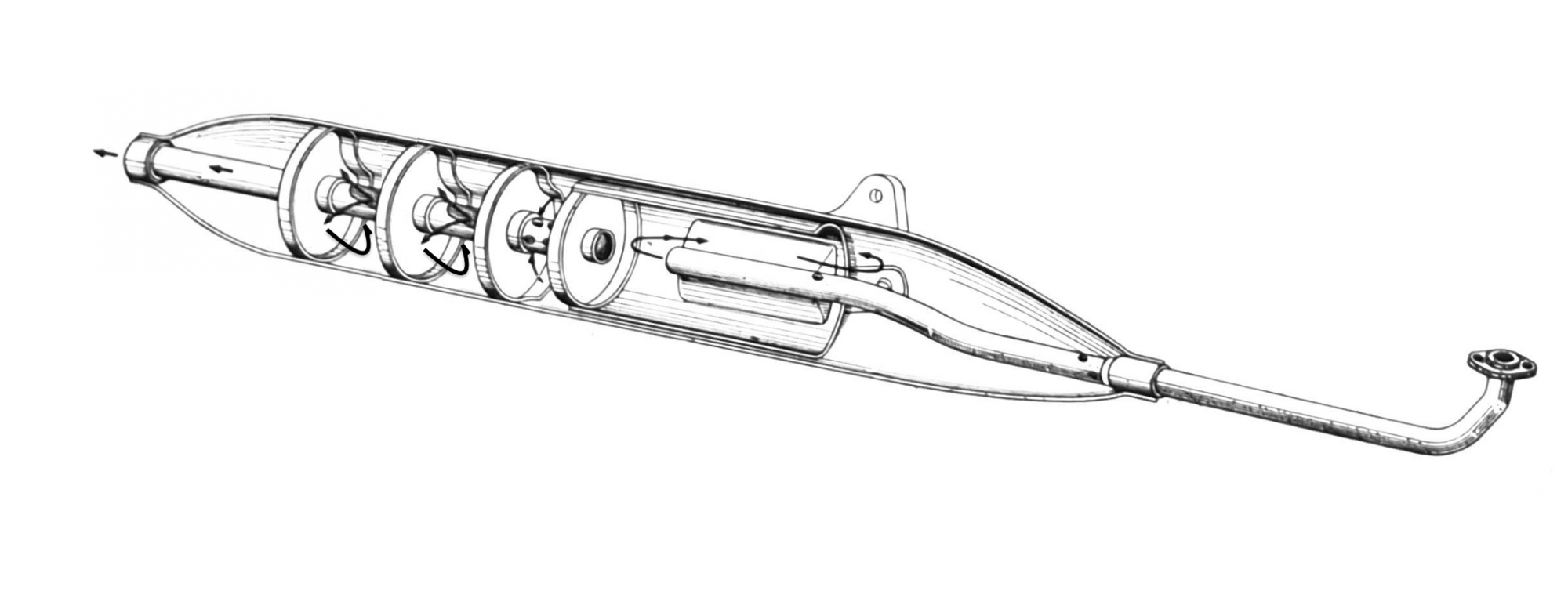

Without a muffler, the high pressure pulsations caused by a combination of the rapid expansion of gas during combustion and the subsequent pulsations caused as exhaust gas is expelled under pressure from the cylinder would cause a right old racket.

The noise is reduced by a series of chambers ("baffles") in the muffler that cause turbulence in the regular gas pulsations, and this disruption to the pressure waves reduces the overall noise.

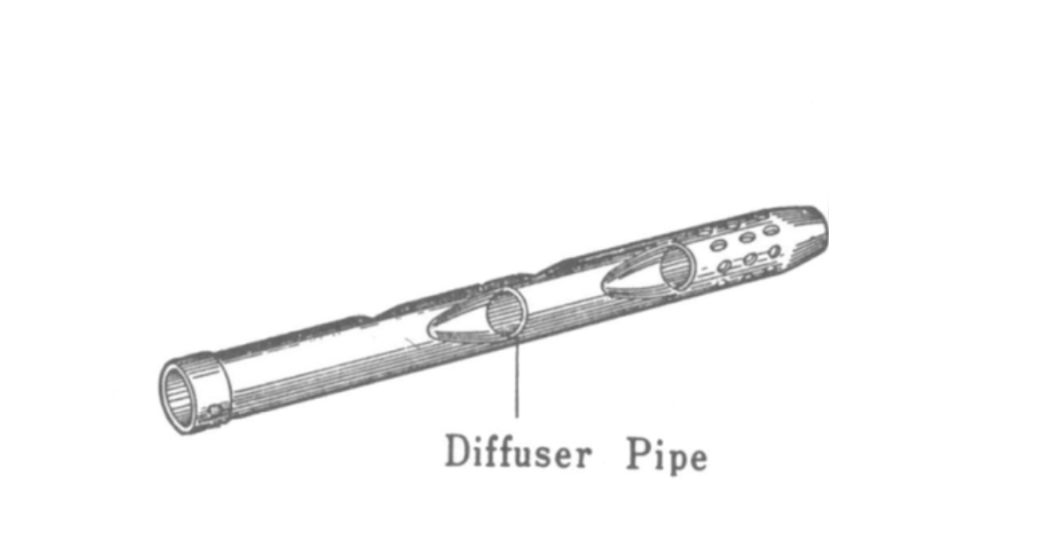

Cross section of the exhaust showing the baffles and flow of gasses through the exhaust. The noise of the engine is further reduced by the incorporation of a diffuser pipe at the muffler outlet - this is removable in later models, including the C90Z range.

Carbon build up and corrosion

Steam is one of the products of combustion and this inevitably contributes to corrosion in the exhaust system, particularly when the engine is not fully warmed up and the steam condenses on the inside of the exhaust. In an attempt to delay the effects of corrosion, there is a small hole on the underside of the silencer to prevent water building up in this way.

Over time carbon builds up inside the muffler and diffuser pipe and this needs to be periodically brushed/knocked out so as not to reduce the flow of gasses leaving the engine (the later 6v models have a removable diffuser pipe to help with this). If the carbon is allowed to build up unchecked the resulting back-pressure can delay the rate that exhaust gases leave the cylinder and, where some of the exhaust gases are left behind as a result, the amount of fresh air and fuel that can be drawn in to the engine is reduced and this can impact performance.

Air cleaner

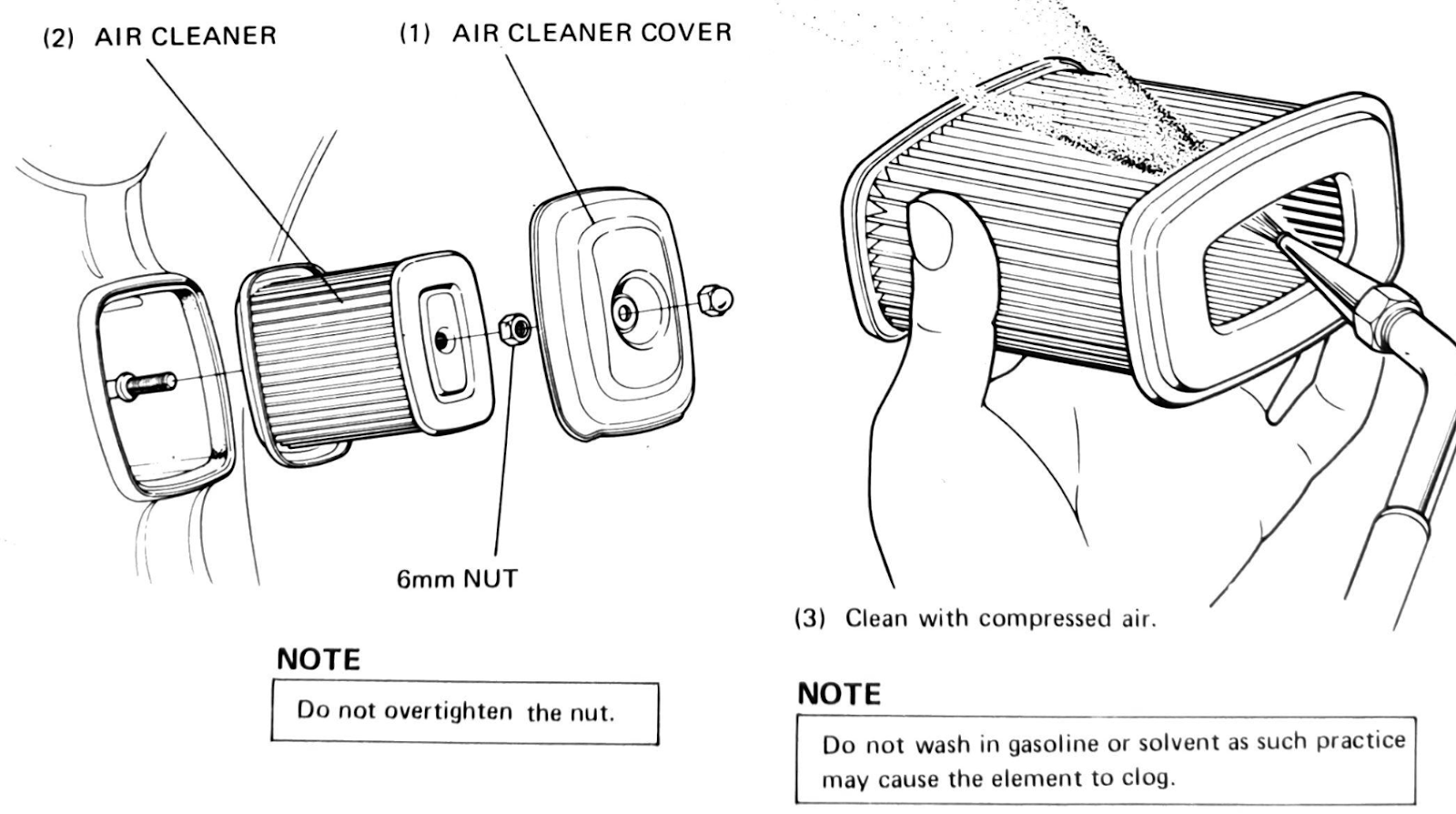

When the engine is running it is drawing a large amount of air and any dust contained in the air that finds its way into the engine cylinders can mix with the oil and result in wear of pistons, cylinders and bearings. An air cleaner is needed to remove the dust particles before the air reaches the engine.

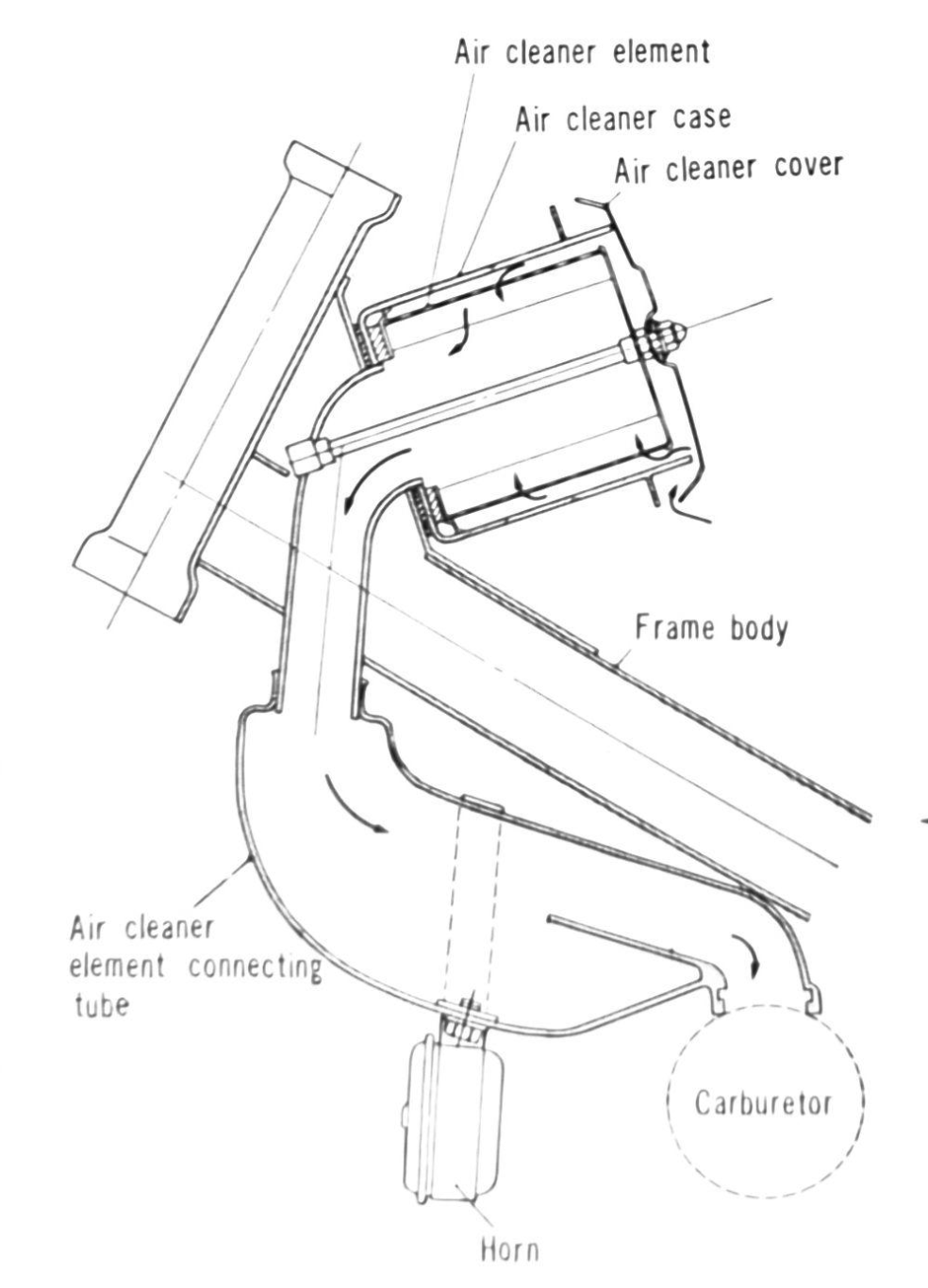

The air cleaning solution Honda contrived for the Super Cubs is rather elaborate. The air cleaner element is a paper filter mounted at the centre of the leg shield:

As shown below, all air entering the air cleaner is filtered and then passes through a welded air cleaner pipe within the frame. After passing through the rubber connecting tube the clean air enters the carburettor. The bulbous rubber connecting tube is designed to minimise noise produced by air flow and to create a repository of still air acts as a reservoir for the carburettor to draw on. The slow moving air is also warmed by the engine, thus helping to vaporise the fuel in the cylinder. Since the paper filter would be harmed by water ingress, Honda went to a lot of trouble to shield the filter from the elements, and the air inlet is well protected from the rain and water splashed from the road.

As you can see, a lot of time and money went into designing this elaborate system for flowing gases through the engine, and the entire air intake and exhaust system is designed to work together to ensure an optimal balance of performance, economy and noise suppression. If you monkey around with aspects of these systems then you risk upsetting this delicate balance, so tinker with care.

Carburettor temperature

One other item of note related to gas flow in the engine is the bakelite insulator that fits between the carburettor and the intake pipe on most of the 6v models

This was fitted to prevent excess heat from the cylinder head being transmitted via the relatively short intake pipe and causing fuel in the carburettor bowl to vaporise.

It seems Honda were worried about the opposite effect on some of the sporty models like the early S90s which, although they shared the same basic engine, used a frame that necessitated a much longer intake pipe. In cold climates, air drawn through the carburettor body can absorb sufficient heat from the carburettor body and intake pipe to cause moisture in the air to freeze, restricting the flow of fuel through the fine ports or jets within the carburettor assembly. To counteract this effect Honda took a feed of oil from the crankcase and passed the oil to the cylinder head via a chamber in the body of the carburettor so that the fuel/air mixture was warmed before entering the intake pipe.

That's the last article on how the bike works, now to get on with putting it back together...