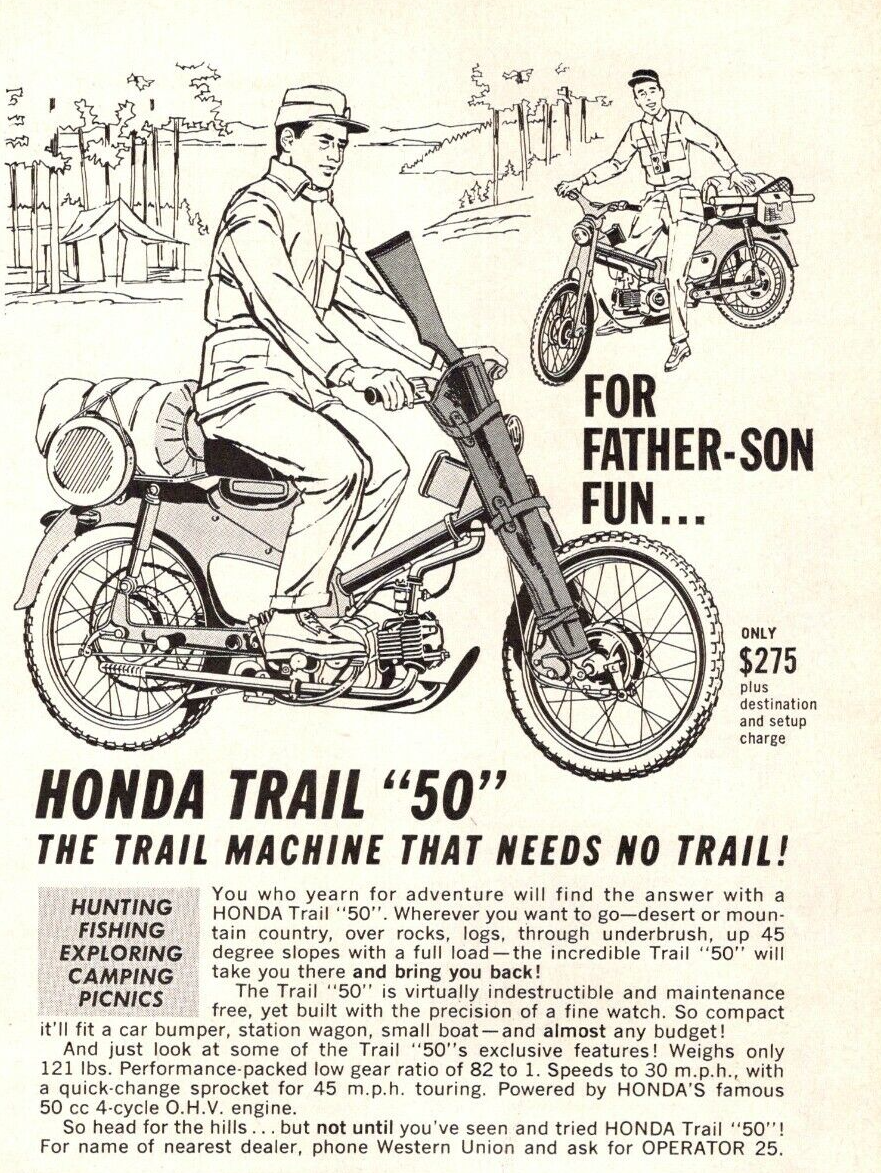

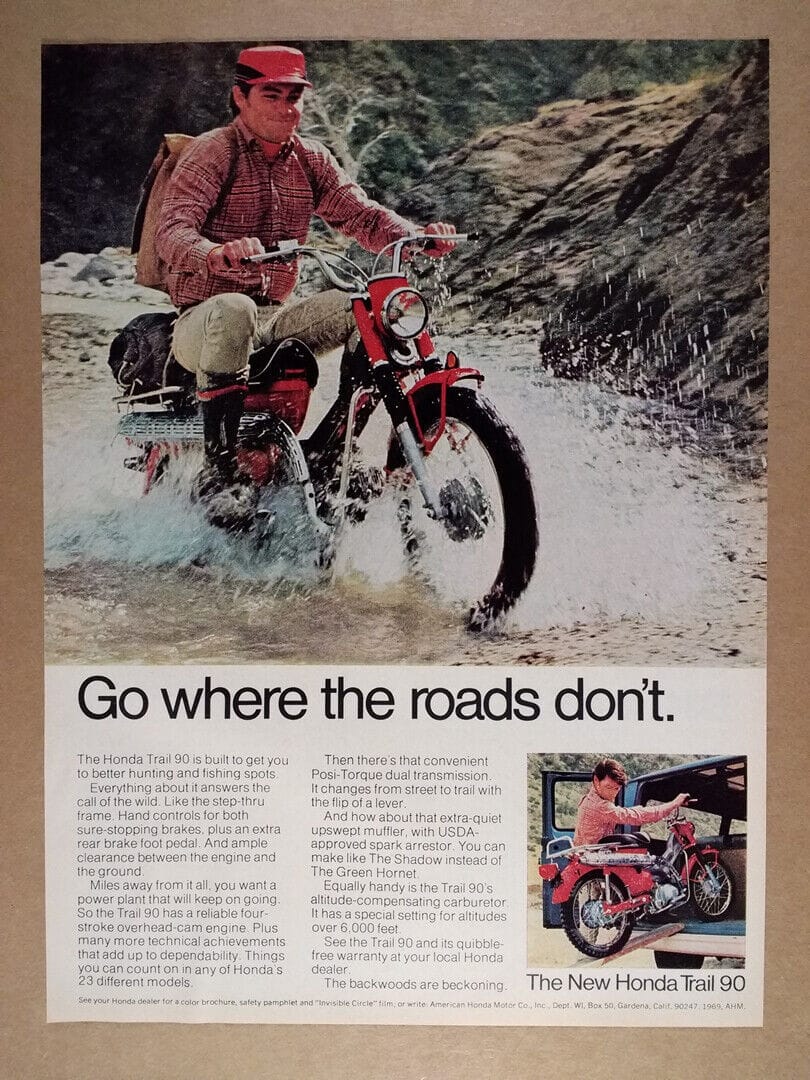

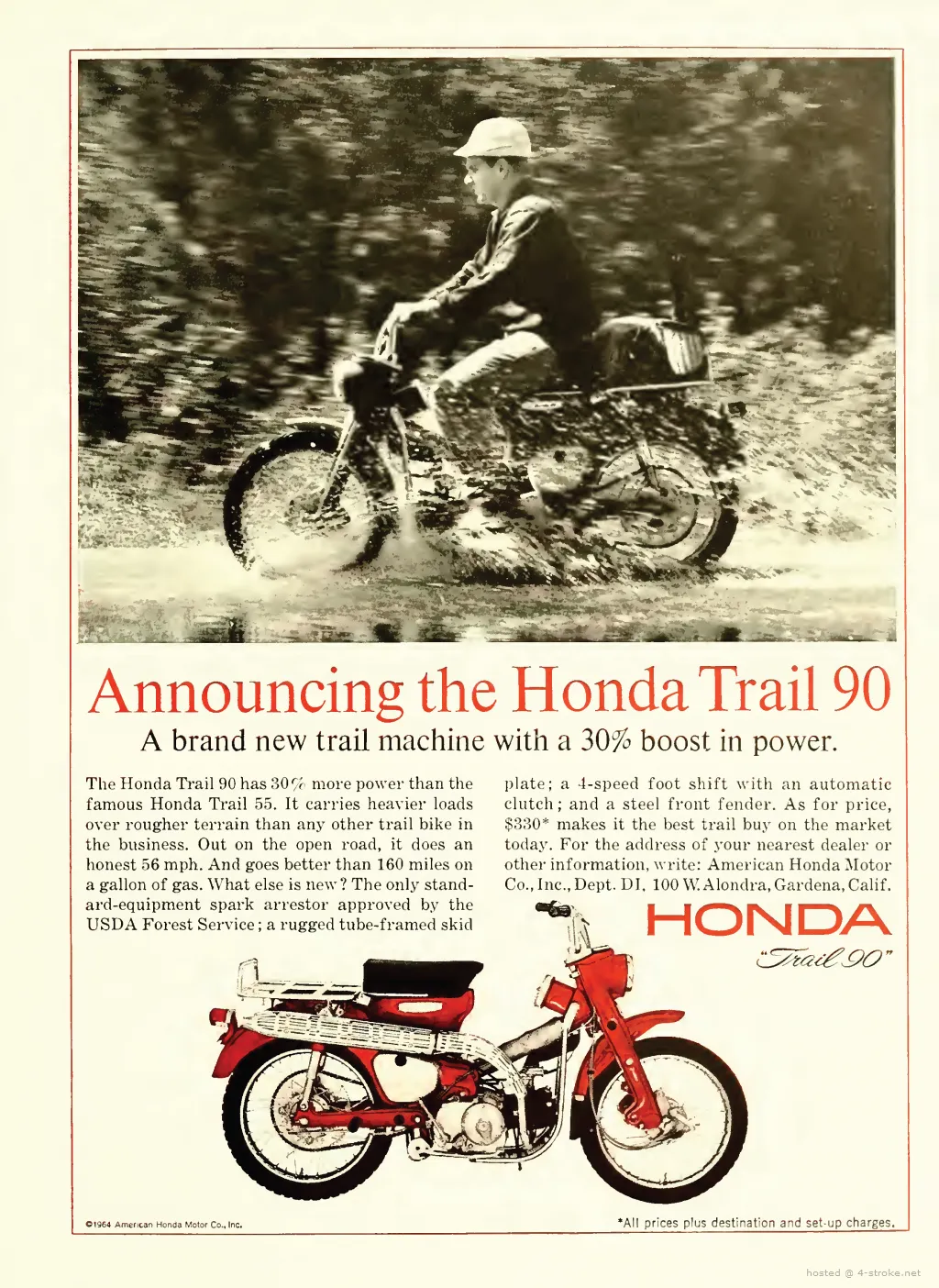

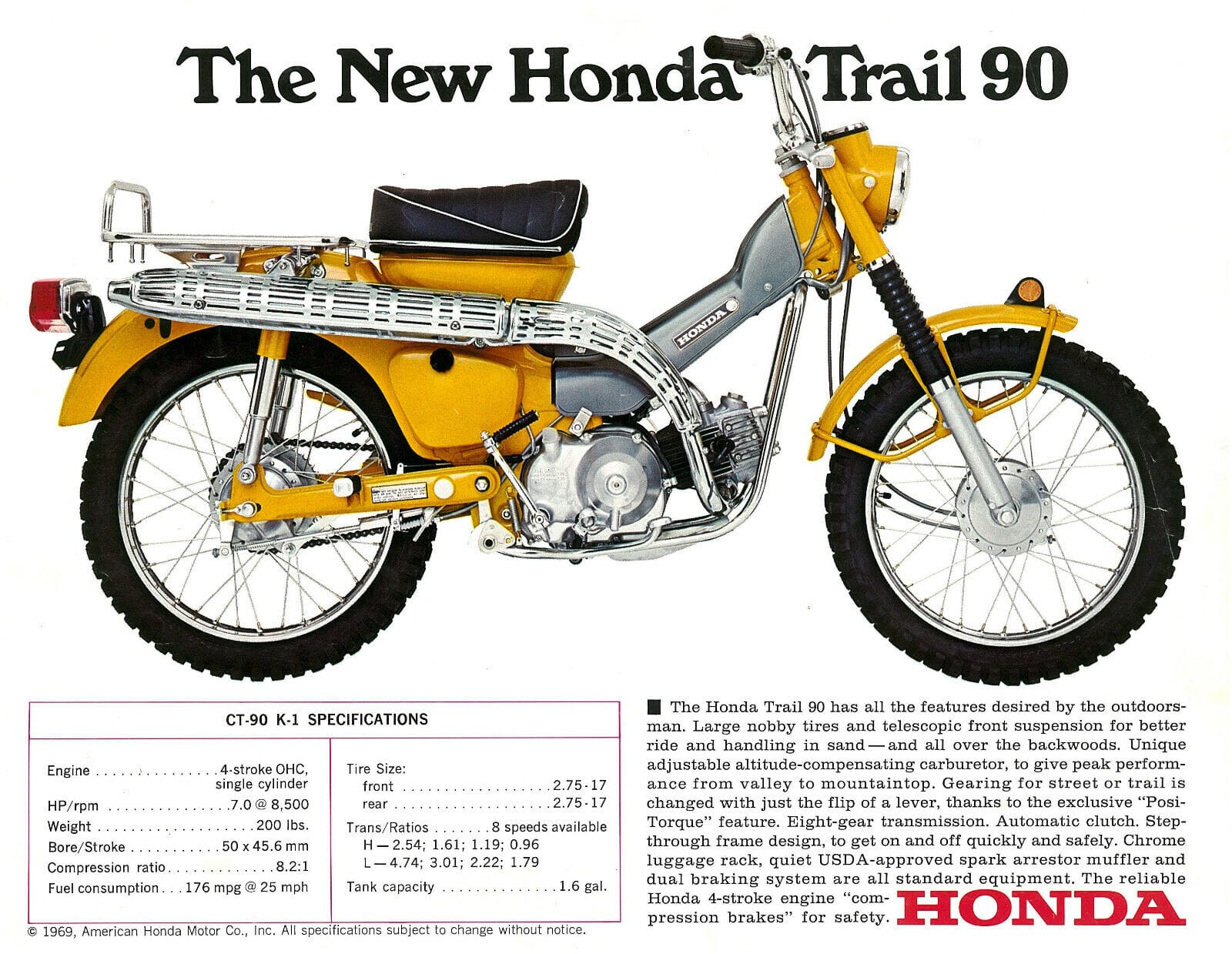

The new upswept design meant the muffler could be mounted close to the seat - helpful when crossing water - and the spark arrestor was needed to help meet federal regulations intended to reduce the incidents of wild fires.

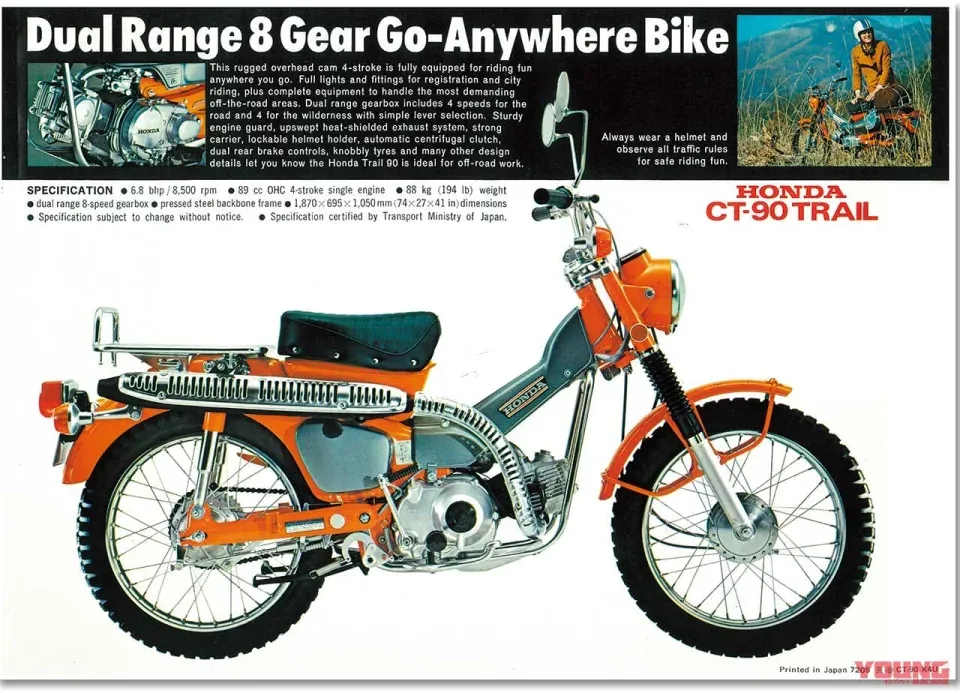

left/centre: The peashooter exhaust fitted to early 'trial' models / right: the new design (the model shown in the advert is an early 1969 k1).

Spark Arresters

Spark arresters are designed to minimise the risk of fires being started by exhaust sparks and are required in the US when using off-road vehicles in national forestry areas. The rules originate with the USDA Forest Service. This organisation was founded in 1905 to protect the national forests in the US, and one of the goals of the organisation was to prevent wildfires which were on the rise, partly thanks to the the increasing use of mechanised equipment in forestry management. The first legislation related to this was passed in 1905 and applied to engines and boilers operated near forests.

In the 1950s the Forest Service became increasingly concerned about fires caused by logging equipment powered by internal combustion engines and commissioned research into the possible use of spark arresters to reduce the number of incidents. This led to the establishment of a spark arrester testing and qualification program at the San Dimas Technology and Development Center, located in California, and this organisation still tests and approves spark arresters - and the equipment they are fitted to - for use in the US national forests.

This is what the Forest Service have to say about it today:

BASIC DEFINITIONS AND TEST STANDARDS

Exhaust Particles—All internal combustion engines produce exhaust particles which are predominately carbon with contaminates. These particles originate from deposits formed on the internal surfaces of the engine or exhaust system and, depending on their exact origin, may be expelled at temperatures in excess of 3,000 °F. Depending on the nature of the contaminates, these particles are capable of glowing or sometimes flaming combustion. When expelled through the exhaust system into the atmosphere, the combustion process may continue or even be accelerated during flight. Such particles, if larger than 0.023-inch in diameter and at temperatures of 1,200 °F, are capable of igniting cellulose materials upon contact.

A Spark Arrester is a device which traps or pulverizes exhaust carbon particles to a size below 0.023-inch in diameter, as they are expelled from an exhaust system. Trap-type spark arresters must have a method for removal of accumulated carbon particles. Most spark arresters generally perform in the high 90 percent spark arresting effectiveness range

United States Department of Agriculture Forest Service - Spark Arrester Guide

Durning the 1960s the rules were extended to require spark arresters on internal combustion engines used in "Off-Highway Vehicles" like the Ct90, and Honda needed to comply.

Krizman spark arrester

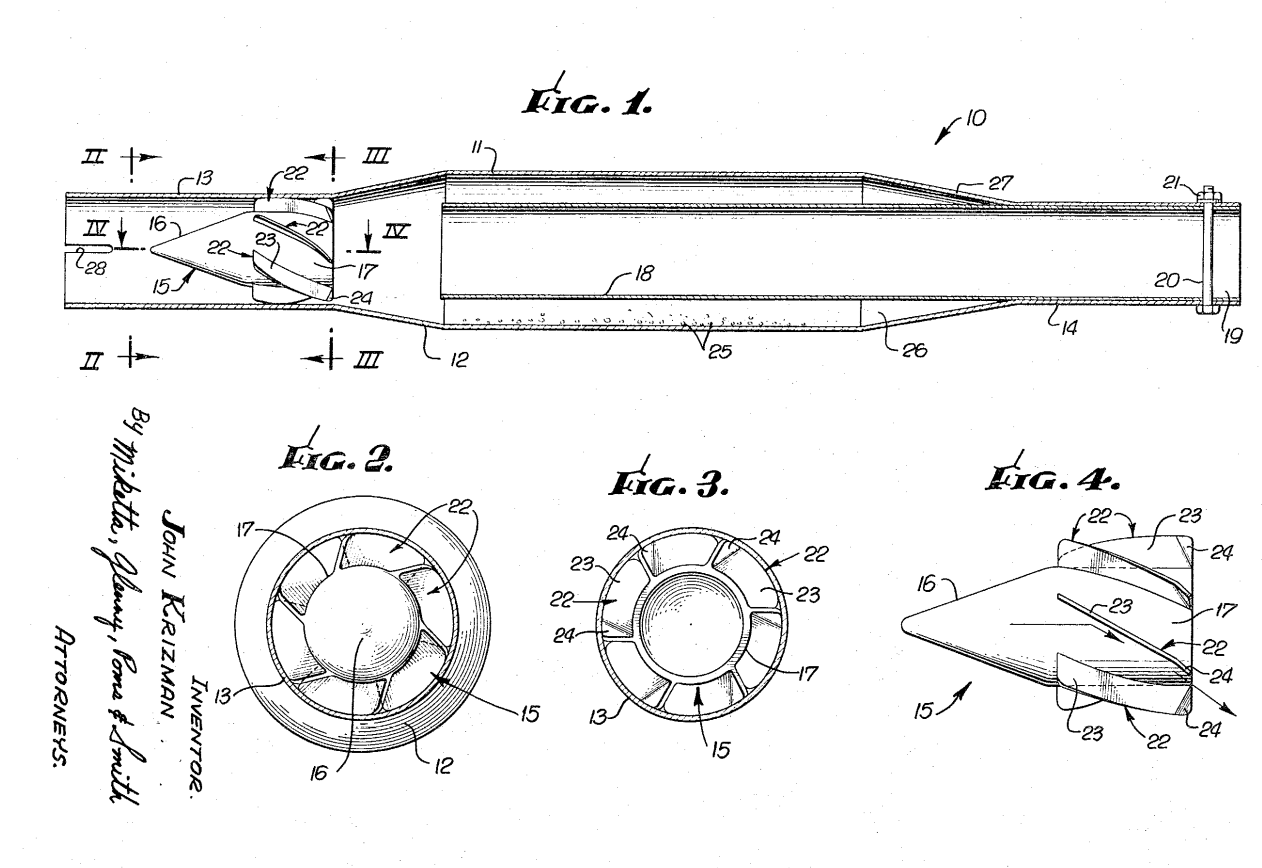

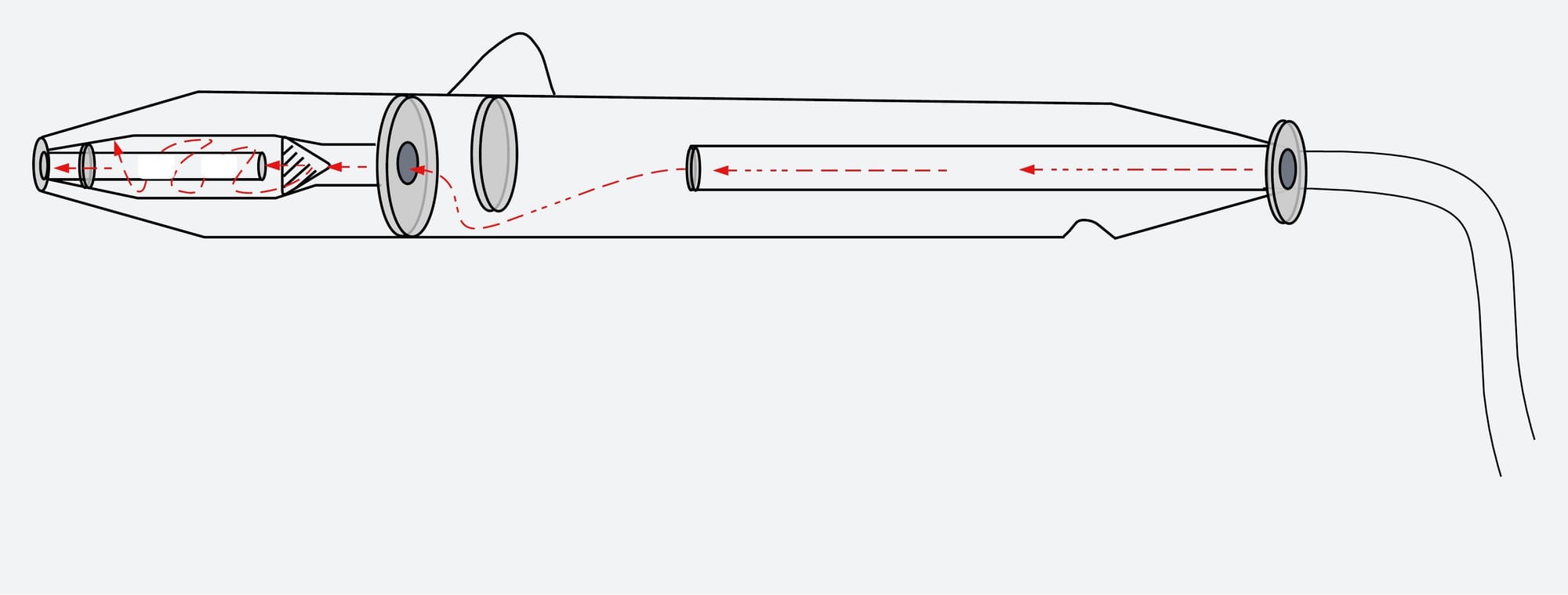

In the 60s it was proving difficult to produce an effective spark arrester for small capacity engines and the existing solutions were either complex and expensive to manufacture or resulted in highly restricted exhaust systems. John Krisman's elegant solution is based on a torpedo shaped section that fits inside the silencer (muffler) part of the exhaust system. The outside of the device is made up of two cones separated by a cylinder with a narrower pipe fitted inside so that a chamber is formed between the cylinder and the pipe. The cone at the inlet section is made of a series of fins laid out of in a spiral pattern so that the exhaust gasses entering through the fins are set into a whirling motion before they enter the wider section of the inlet cone. At this point the momentum of the large carbon particles causes them to bypass the internal pipe so they become trapped in the chamber between the pipe and the walls of the cylinder.

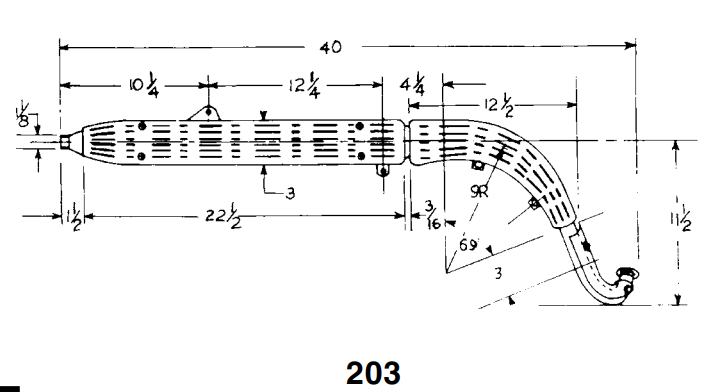

You can see the original patent drawing below, next to a sketch of how it was implemented on the CT90:

left - US3407575 patent (1968) / right - CT90 exhaust

This design was simple to make and minimised the additional restriction on flow through the exhaust. It was an immediate success and Krizman licensed it to Honda, Suzuki, Yamaha and Kawasaki as well as brit bike makers like Triumph and BSA who were producing off-road bikes for the US market.

Diffuser vs 'Snuff or Nots'

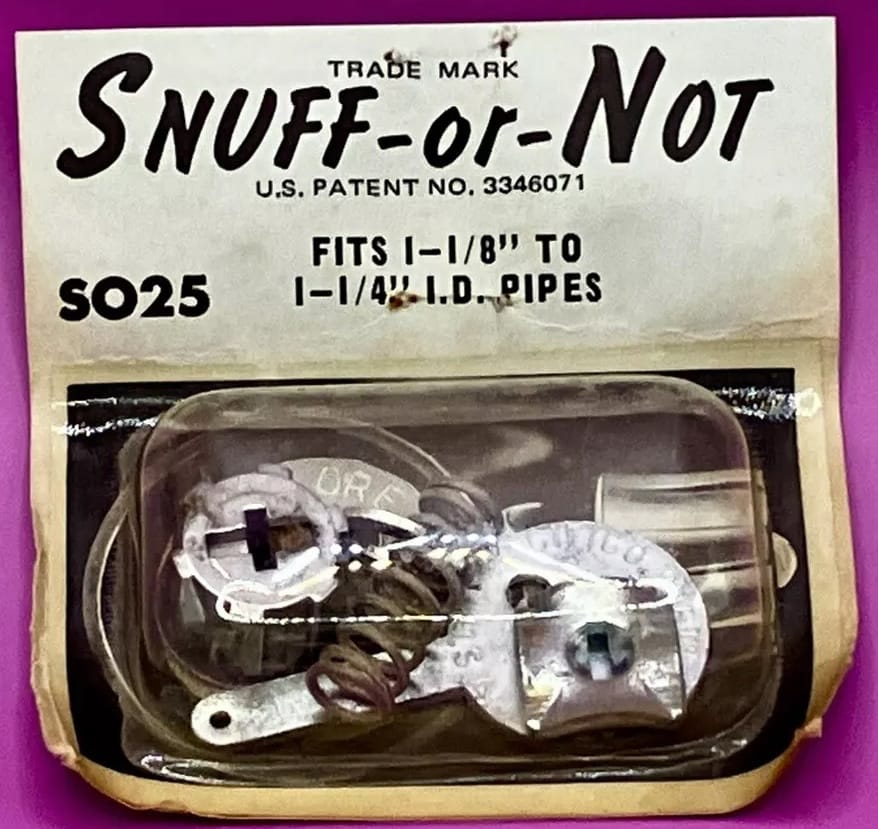

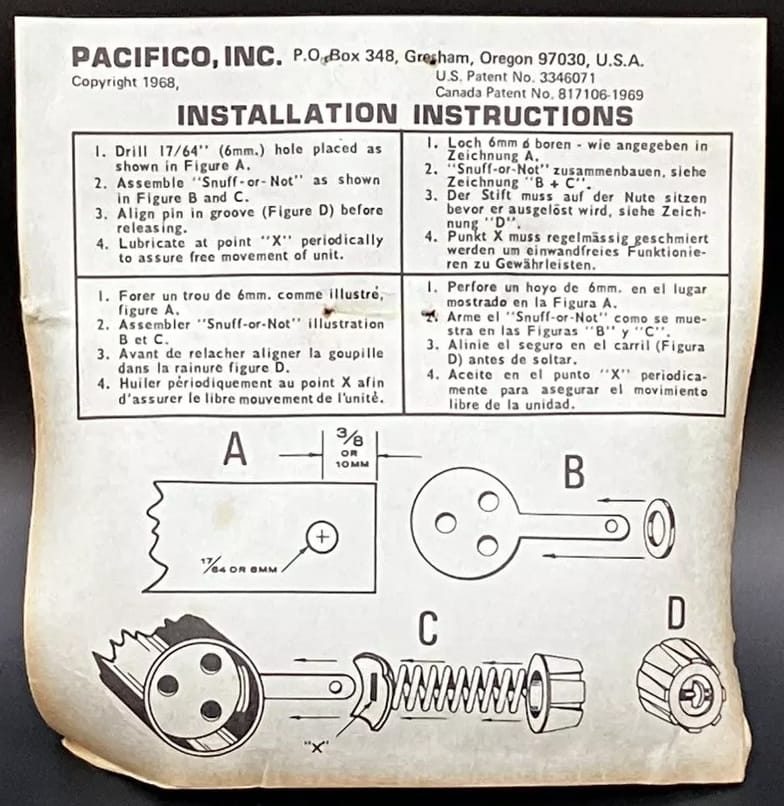

The diffuser - which acts as a baffle to reduce noise - is removable to allow cleaning, and back in the day this also created the opportunity fit a canny device called a 'snuff or not' that could render your motorcycle obnoxiously noisy at the the twist of a knob.

According to the inventor, Allan Lader, the standard diffuser raises the back pressure against which the engine must work, and thus decreases the effective horsepower of the engine, so - if the marketing is to be believed - fitting one of these devices means you will be tapping the full potential of your mighty 7hp engine! Happy days!

1970 advert (cycleworld) and packaged product

apparently hundreds of thousands were sold after their invention in 1964.

Model Approval

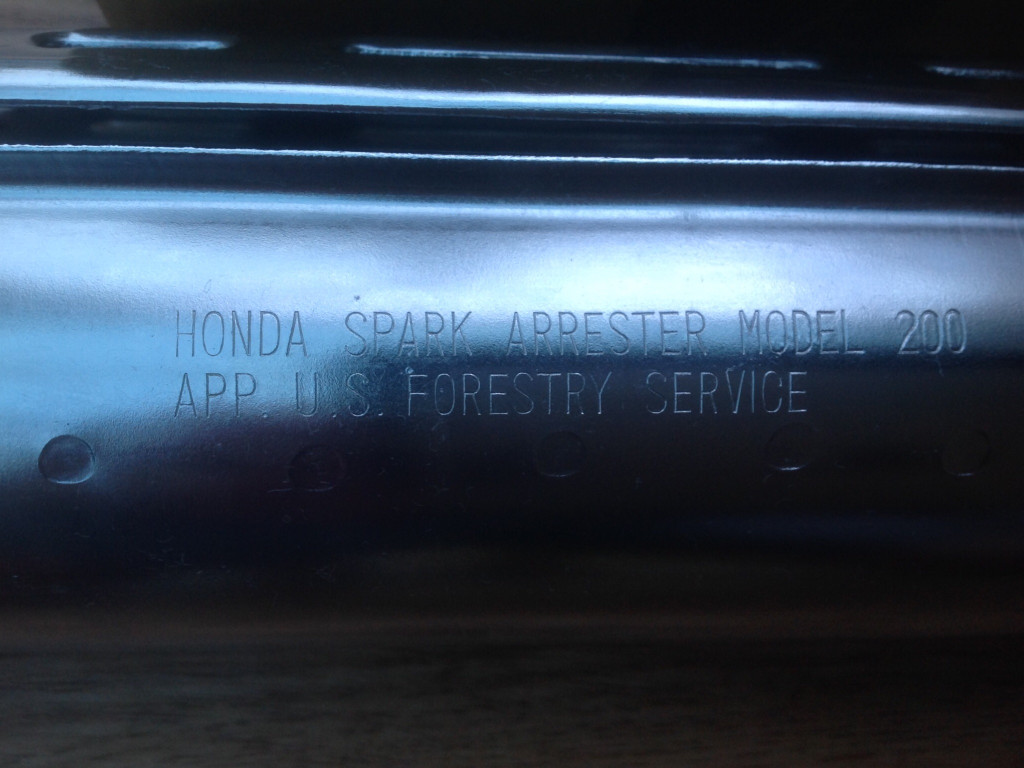

The original 1968 Ct90 exhaust system is stamped with the approved spark arrester model number (model 203) and this model is still listed in the latest Forest Service Spark Arrester guide.

The Honda labelling on the exhaust, as required by USDA Forest Service legislation (left) / the identification picture from the latest Forrest Service Spark Arrester Guide (center) / diagram of the inside of the honda exhaust (right)

Earlier Versions

The exhaust fitted to the first 90 trail when it was introduced in 1964 was also USDA FS approved but used a different kind of spark arrester (model 200). The later 203 model fits all the CT90s, k1 and upwards.

Later versions

The 1970 K2 came with a new heat shield design and was the last model to be fitted with a chrome exhaust, all subsequent versions were black.

1969 K1 (left) / 1972 K4 model with the new heat shield design and all-black muffler

Replacement exhausts

The ct90 exhaust is still available from Honda, although only the later black version. It is no longer stamped with the spark arrester model identification although the spark arrester still appears to be installed. As far as I can tell the legislation is still in place and requires the exhaust to be stamped, so this is a bit puzzling. Perhaps the common fitment of catalyst-converters - which effectively trap large debris within the channels of the catalyst substrates - on modern engines mean the spark arrester rules get less attention nowadays.

(left) original exhaust system on top and new Honda replacement below / (centre) you can see the 'whirler' - part of the spark arrester - after removing the diffuser pipe / left - no USDA FS markings, but a warning is included pointing out it no longer conforms to modern emissions and noise standards.

Maintenance

The big hole in my original exhaust created an ideal opportunity to have a look at what was going on inside, but sadly much of the mechanism - including the whirly bit - had rusted away.

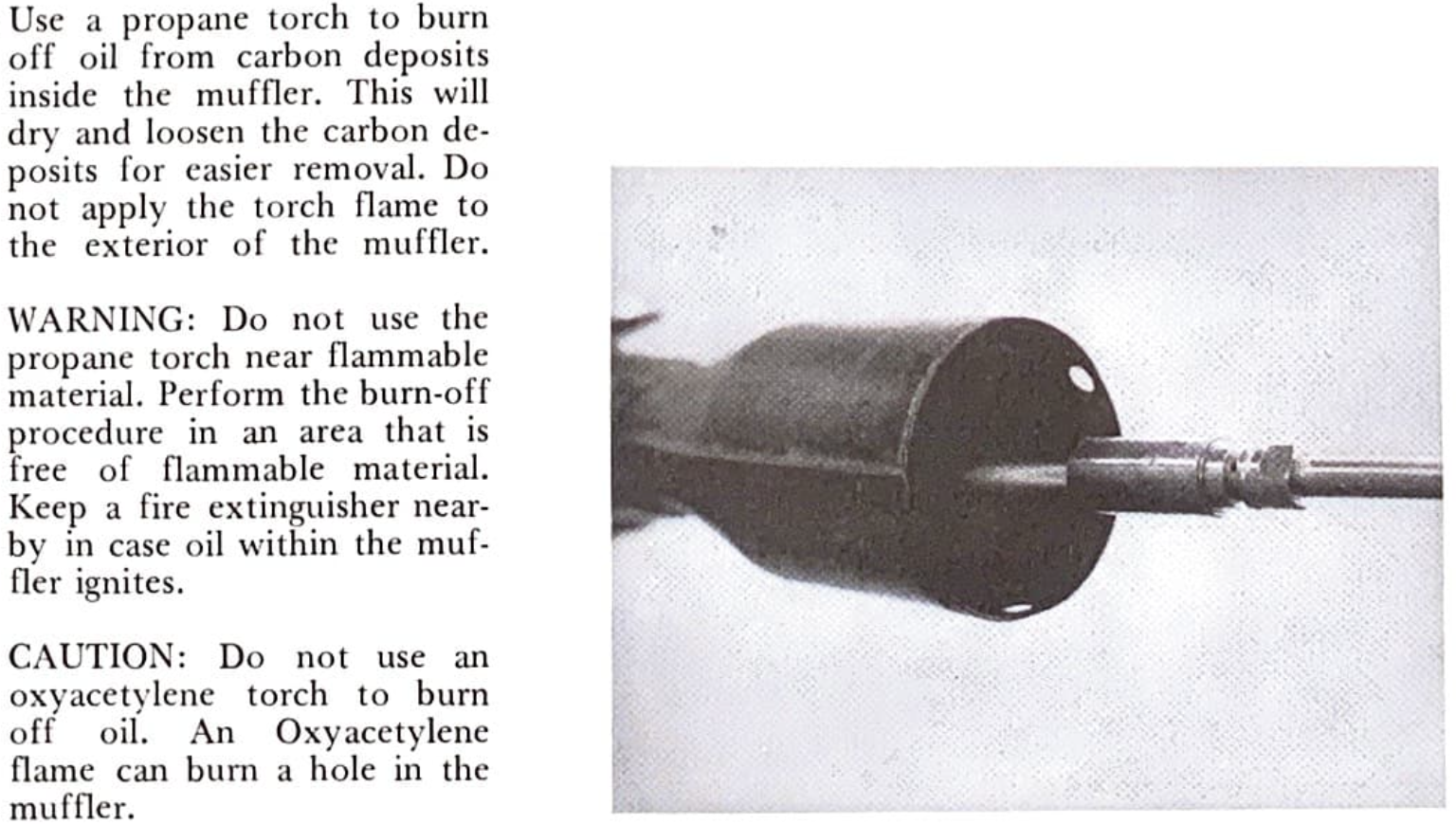

The Forest Service regs require that there is a way to remove the carbon deposits that build up in the spark arrester carbon trap, and this is done on the CT90 by removing the diffuser inserted in the end of the silencer. This needs to be cleaned out periodically since, once the carbon trap becomes full, the performance of the spark arrester is impaired.

My original exhaust was not repairable, so I was relieved to find a replacement rust free chrome version (a very lucky find in the UK, and only £70). A bit of banging and shaking got rid of most of the carbon, and I burned off the remainder left inside the spark arrester with a blow torch.

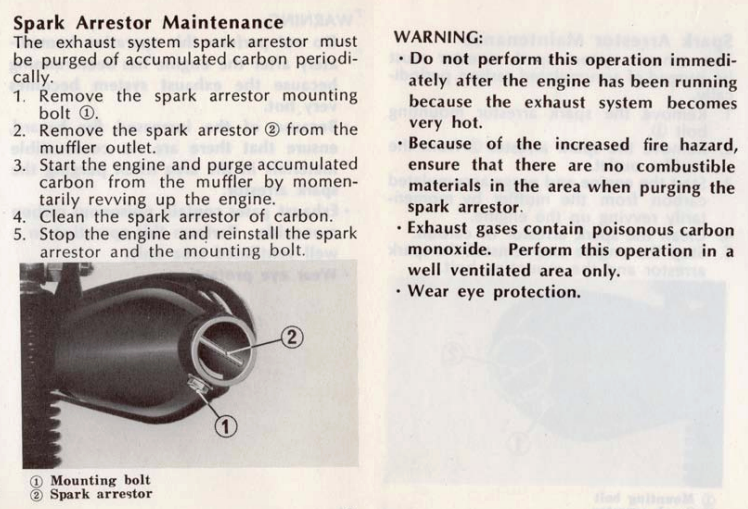

As per the below excerpt from the workshop manual, if the exhaust is installed on the bike you can run it for a bit without the diffuser to blow out any carbon deposits.