Record 52 ½ vices have been an essential tool for woodworkers all over the world for more than a century. They have arguably never been bettered in design nor quality - you can read about their long history below.

The first model (1910)

C&J Hampton registered the ‘record’ trademark in 1909. Trade listings from the time show that they owned a foundry and were manufacturing vices and other tools. By 1909 the patent protecting the very popular Parkinson quick release vice had expired so there was nothing to prevent C&J Hampton from simply making a copy, and this is what they did.

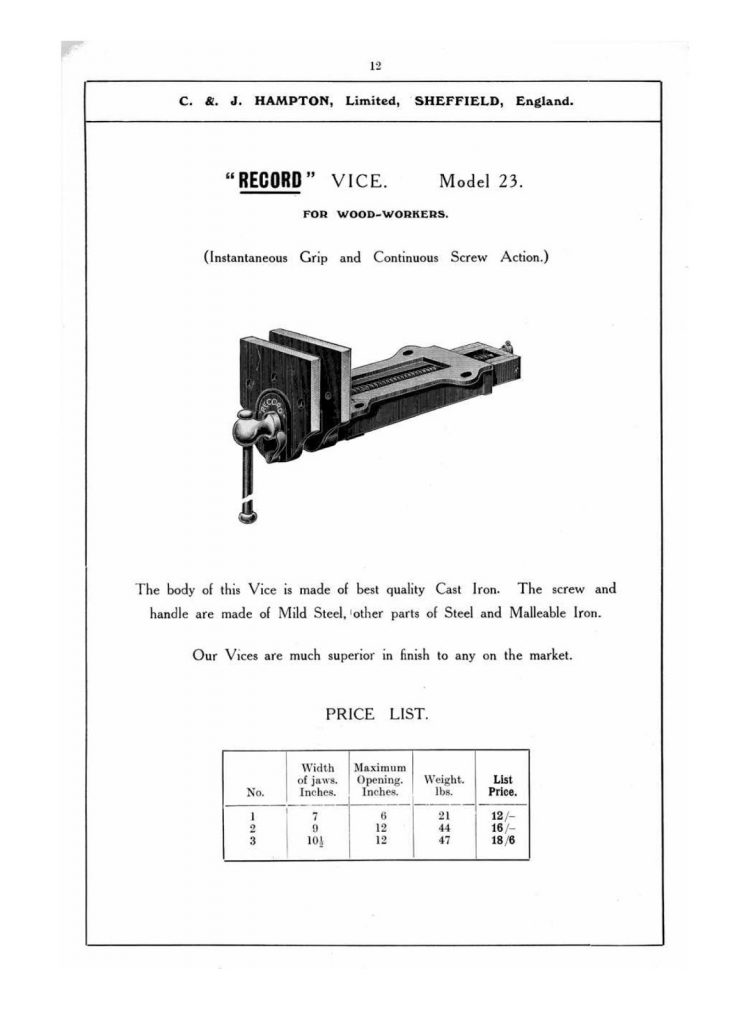

Record ‘Model 23’ – an almost exact copy of the Parkinson design of the time

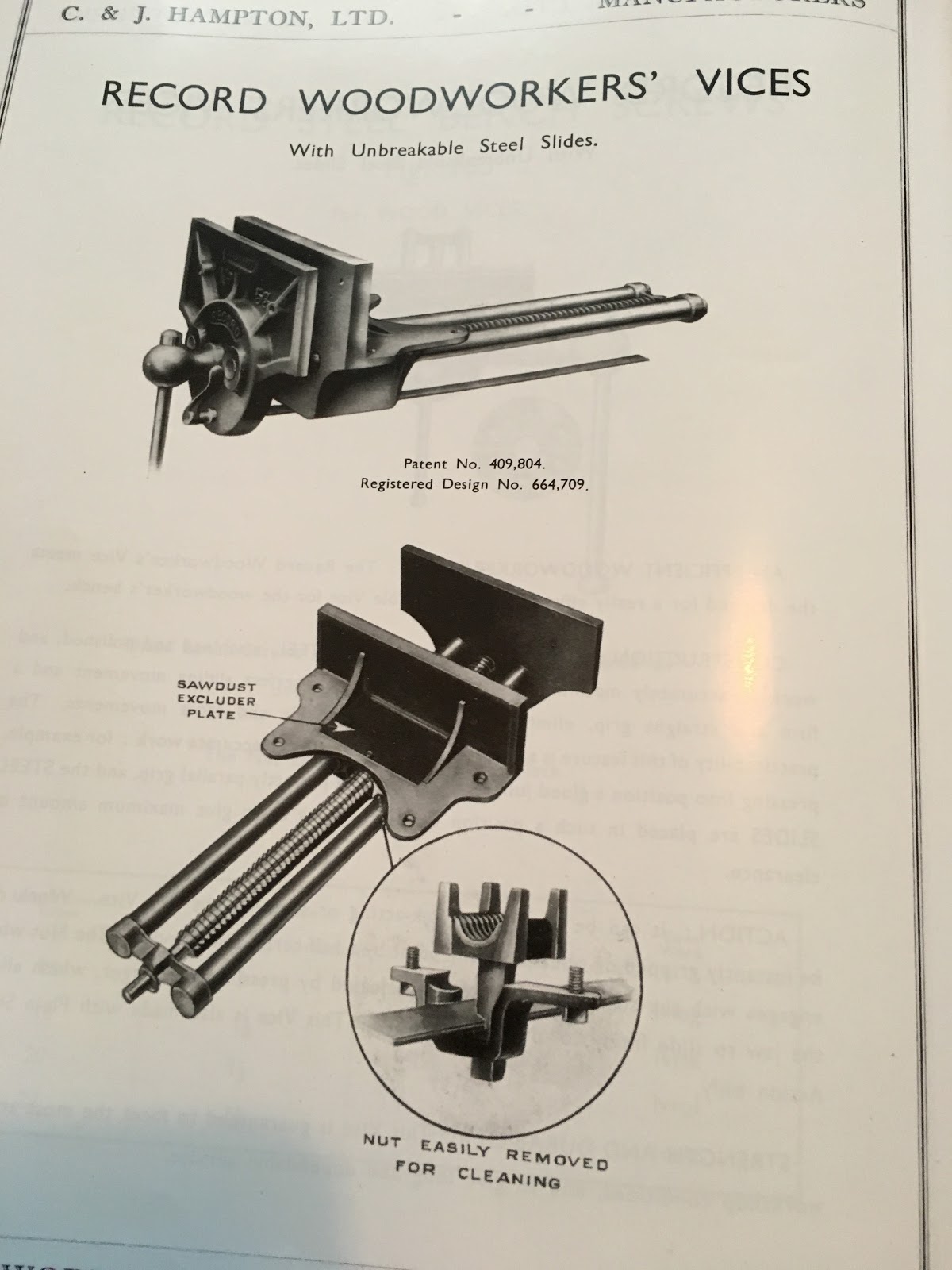

The Tools and Trades History Society have made an early C&J Hampton catalogue (June 1910) available to members, and the model 23 vice gets a full page spread:

C&J Hampton catalogue (1910) – available from TATHS (members only)

In this catalogue the ‘Record’ trademark is only used for their vices and was presumably registered, at least initially, for this purpose. The catalogue also advertises wrenches, spanners, cramps and tube cutters, holdfasts and a few drills; but the vices were clearly an important part of their range and they used "VICES, SHEFFIELD" as their telegraphic address[2] accordingly

The original Parkinson's vices had been very successful and were copied by other makers, including Steel Nut & Joseph Hampton ltd (aka Woden) as can be seen in their catalogue from a few years later:

Woden catalogue 1918 - their Parkinson pattern vice is shown in the centre

Tony Hampton, a distant relative of the founders of these two companies who had worked for the Woden business, told Scott Landis[3]:

Hampton's great-great grandfather, Joseph Hampton, started the Woden Company around 1870 in Birmingham. When Hampton's grandfather, Charles, and great-uncle, Joseph Hampton, moved to Sheffield in 1898 to start C & J. Hampton Ltd, they brought the Woden line with them and began making vices patterned after Woden's. Woden tried, unsuccessfully, to sue, but the vises were unprotected by patent.

Scott Landis, the Workbench Book

This may be a reference to older Woden vice design as it would be odd for Woden to sue C&J Hampton over their 1910 quick release vice which, after all, Woden had themselves copied from Parkinson after his patent expired.

1918-1930

Version II – Steel Rods (1918)

C&J Hampton, released a new version of the vice in 1918 and retained the ‘Record’ trademark.

The new version improved on the previous model by the use of steel rods rather than the cast steel slides used in the copy of the Parkinson vice. The cast iron sliders were comparatively fragile and the polished steel rods afforded a smoother mechanism. This was a better design and all the major GB manufacturers had switched to it (including Parkinson) by the 1930s.

Record take credit for introducing this improvement (see catalog entry below) but can’t claim to have had the original idea since, as we saw previously, WC Toles, a US maker, was using steel rods in his vices over 20 years earlier:

Record pocket-edition catalogue no 16 (1950)

The likely launch date for the new model was 1918, which is the date of the Registered Design that is cast into the front jaw of these vices.

Two face castings were used, the design that omits ‘MADE IN ENGLAND’ is relatively uncommon and is presumably the earlier version.

version II a [1]

Version II b (“MADE IN ENGLAND”)

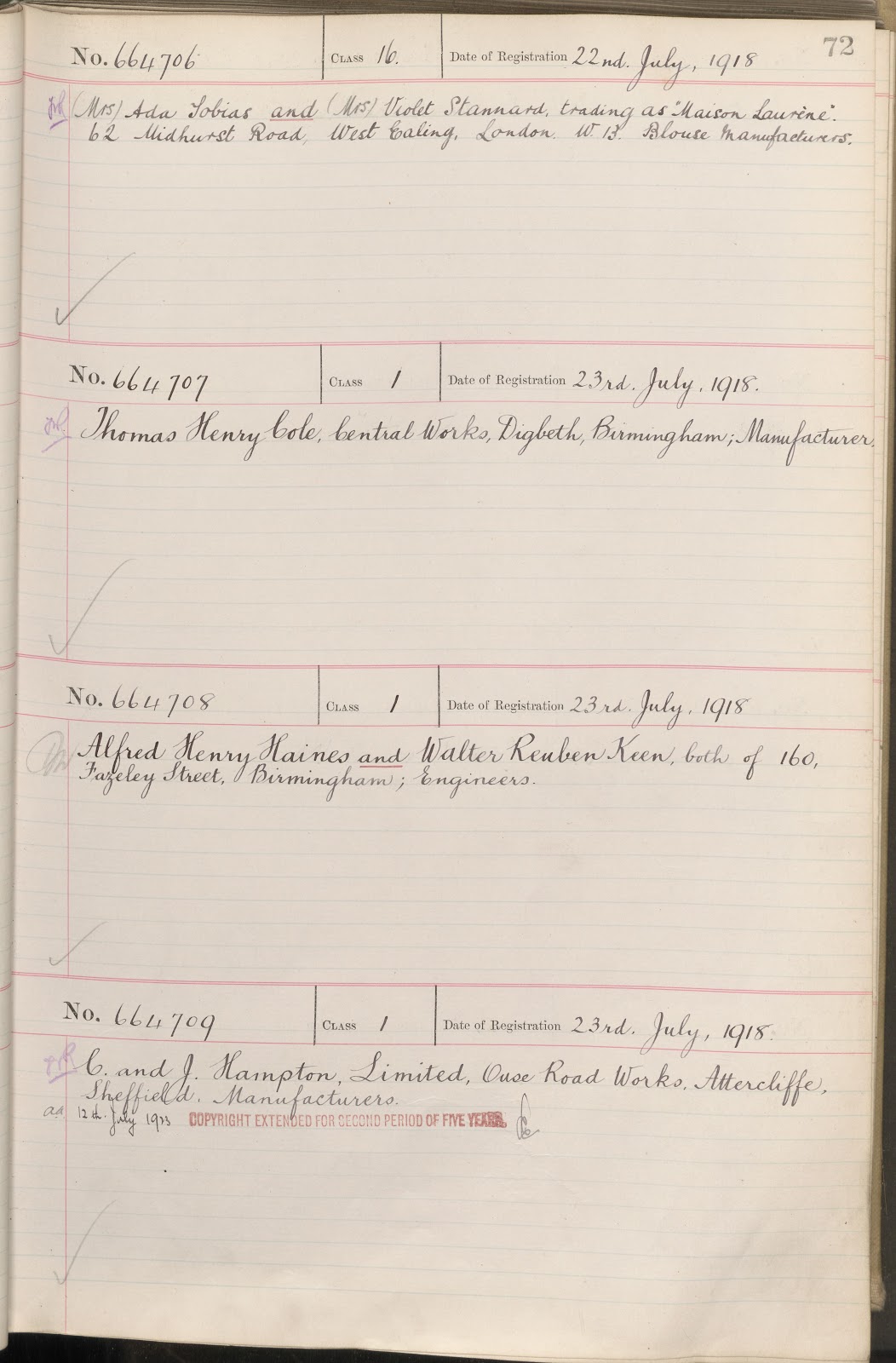

Since there were no original inventions to patent, a registered design would have been the best C&J Hampton’s could have done to get some protection for the new model. The registered design reference is 664709

I contacted the National Archive to get a copy of the design registration records to see if it offered any clues (search and copying fee of £9.10 – no need to thank me!)

As you can see the date it was filed was July 1918 and an extension was noted in July 1923.

the 1907 Patent and Design Act granted you 5 years copyright under a design patent with the option to extend for two more 5 year periods.

But, as noted below, it seems that C&J Hampton continued to stamp the RD number on the vices they made well into the 1930s.

My best guess is that Record did renew for the third and final term granting them design rights until July 1933, but that they had enough old stock of the ‘RD’ casting to carry production a little while after it expired.

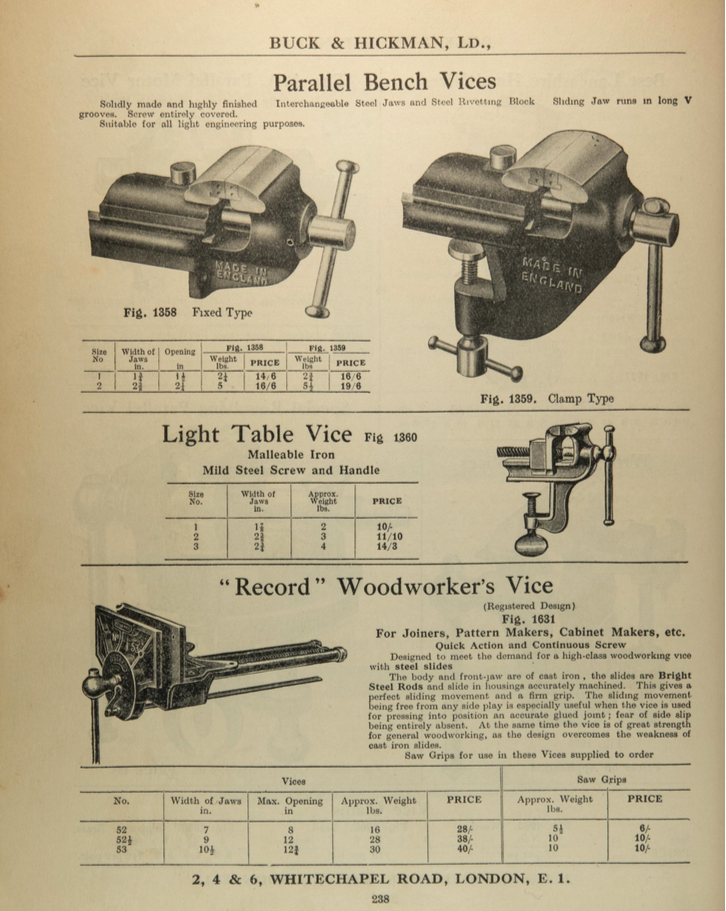

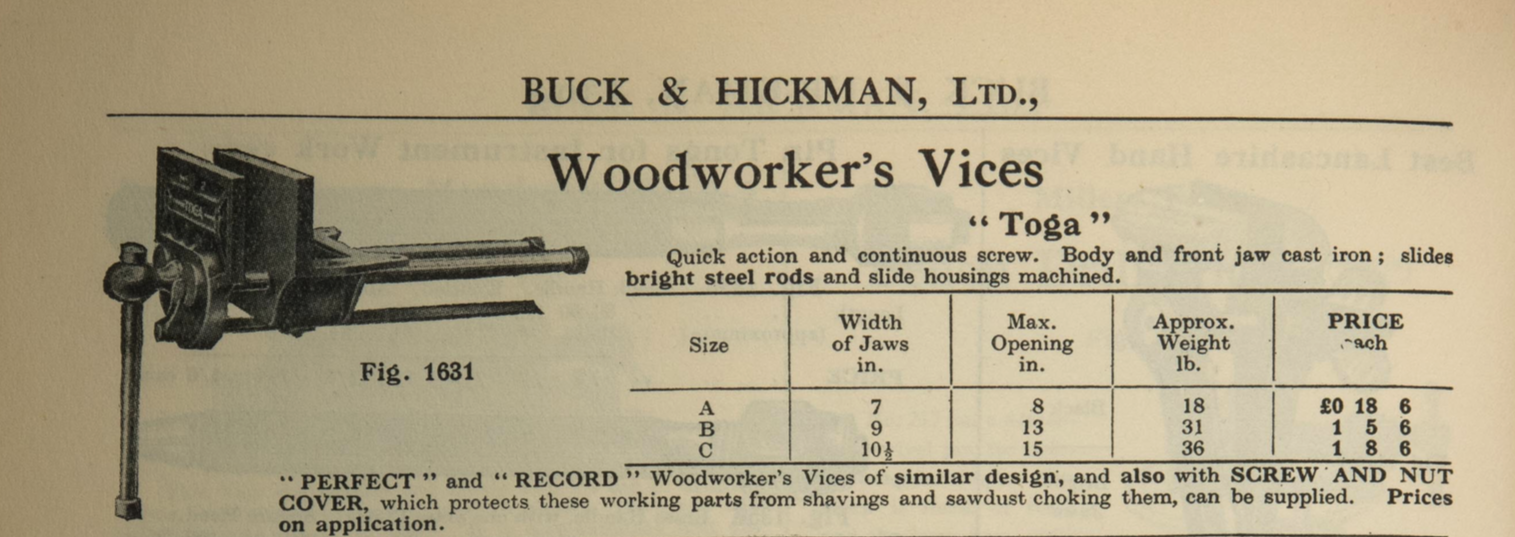

Presumably production of the new vice started soon as the design patent was filed with the GB patent office, but the earliest evidence of the vice being for sale that I could find is this 1923 catalogue:

Buck & Hickman 1923

The best we can say is that any of the vices with an RD stamp were made between July 1918 to 1933 or thereabouts.

Version III – screw and nut cover (1927)

Eventually Record came up with a couple of improvements that they considered worth patenting.

The first idea is actually rather good, but the second, described below, is a bit of a duffer (it does at least help with constructing a timeline for the vices).

A weakness of Parkinson’s quick-release design – perhaps the only serious issue – is that the screw is exposed when the vice is opened and sawdust and any shavings that fall on the screw can be carried onto the half-nut. If enough debris builds up it can cause the half-nut to ride up the screw thread causing the mechanism to slip, potentially damaging the threads in the process.

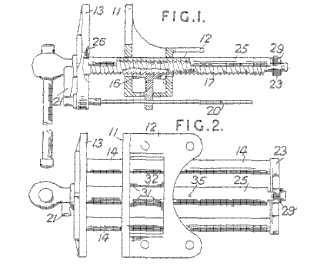

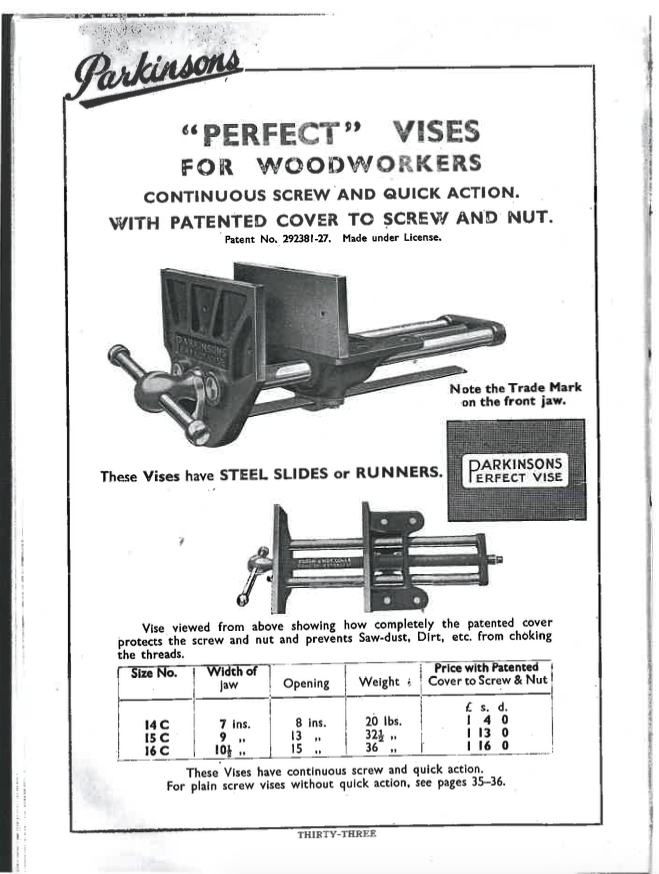

In August 1927 Record took out a patent (GB292381) for a “Screw and Nut Cover” – this is a metal cover that extends the length of the screw, preventing sawdust and shavings dropping on the thread. An excellent idea.

Drawing from the Patent

These vices were sold along side the original version and designated e.g ’52 1/2 A’ where ‘A’ indicates the screw and nut cover version. The As were about 10% more expensive than the standard model.

52 1/2 A (screw and nut cover)

Around this time they also moved the spring that held the half nut against the screw to the front face. The older vices used a captive spring between the half-nut housing and the underside of the half nut to keep the half-nut pushed against the screw until the lever is turned and the spring compressed.

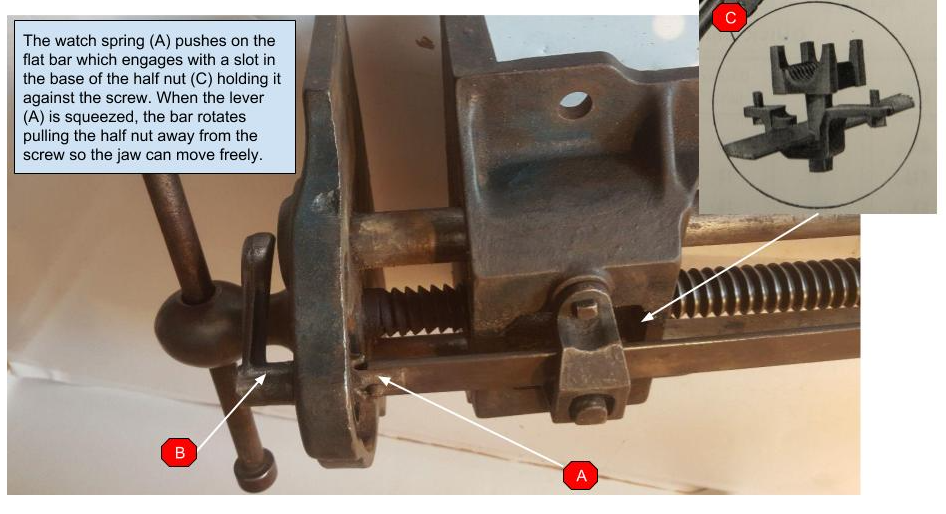

In the new design the flat bar is inserted into a castellated nut on the inside of the front jaw and it is held under tension by a large watch spring. The spring causes the bar to push the half nut against the screw until the quick release lever is activated.

1920s quick release mechanism (left). The new design (right) has a cut out on the face of the vice needed to accommodate the spring. This must have been vulnerable to damage and it was reinforced in later versions (there was a corresponding change in the face plate with the inclusion of a slight bulge under the trigger).

Version IV – sawdust excluder plate (1932)

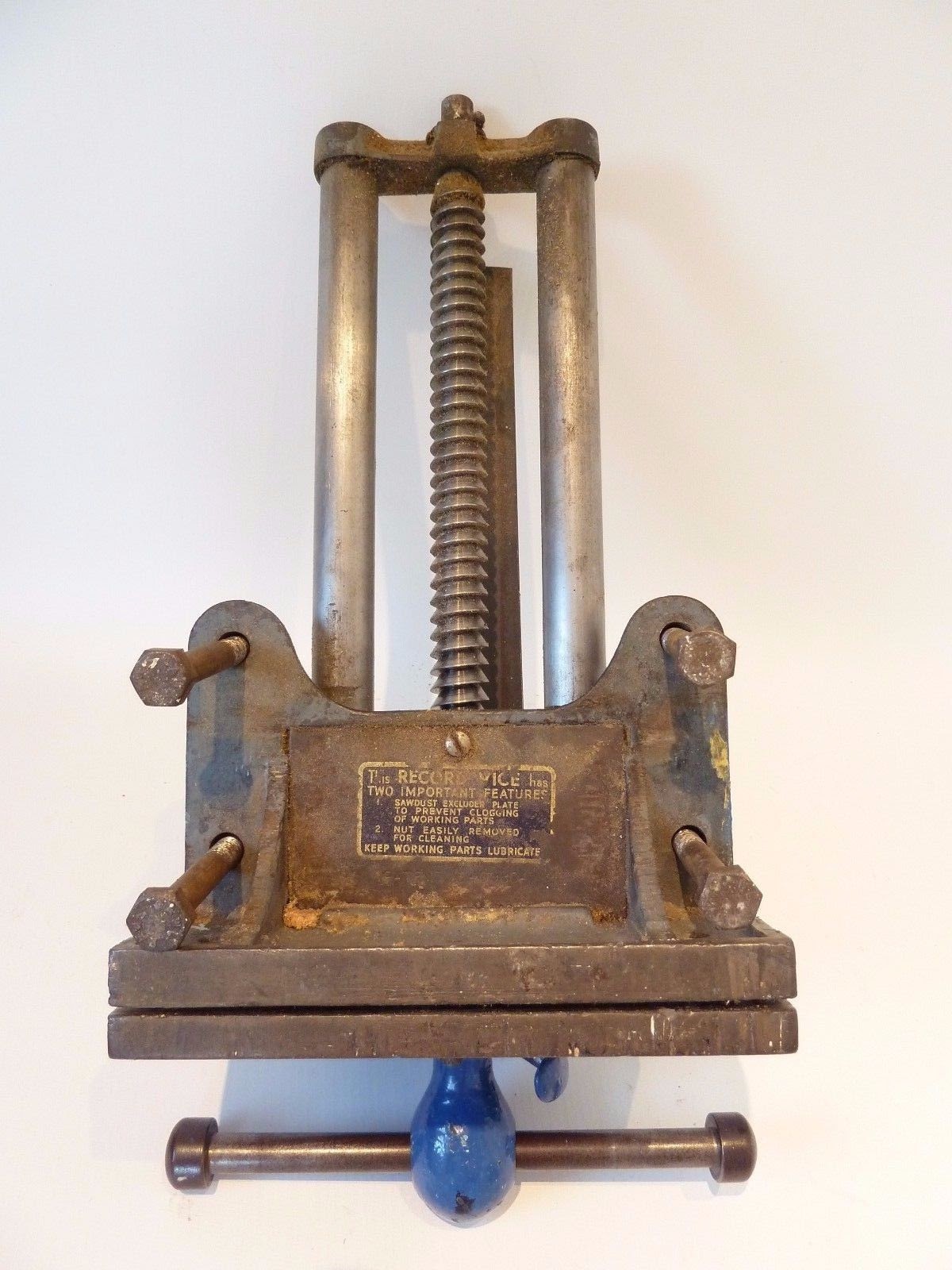

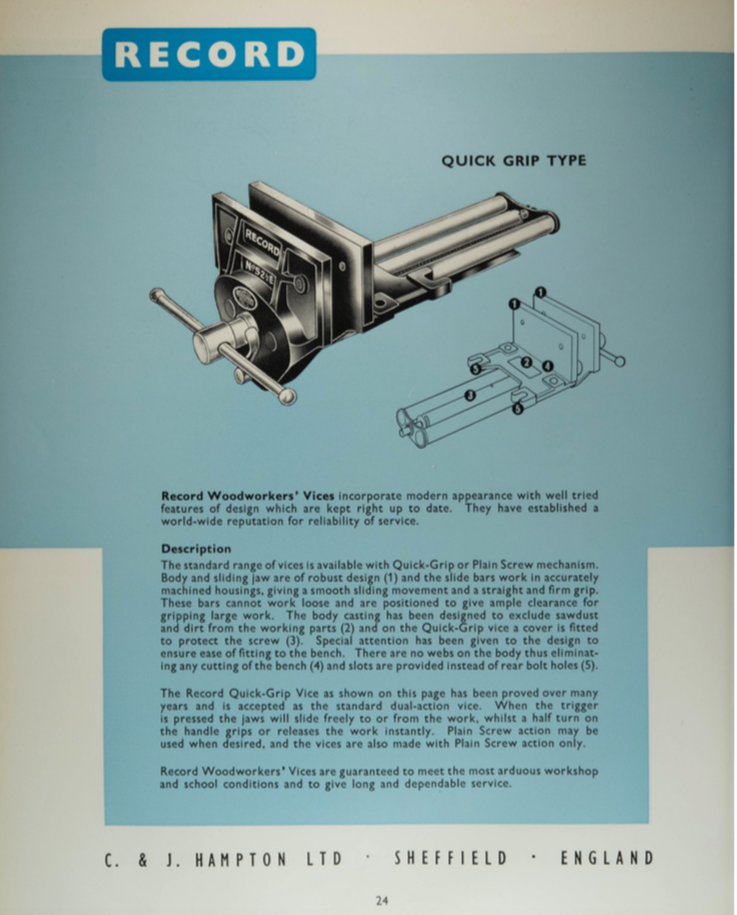

in November 1932 Record applied for a new patent, this time for a “sawduster excluder plate” that covers the housing for the half-nut. This change was introduced at the same time as a modification to the housing for the half-nut and they put a blue and yellow sticker on the plates to explain the changes:

The RECORD VICE has TWO IMPORTANT FEATURES

1. SAWDUST EXCLUDER PLATE TO PREVENT CLOGGING OF MOVING PARTS

2. NUT EASILY REMOVED FOR CLEANING

KEEP WORKING PARTS LUBRICATED

You may wonder how a part of the vice that is fixed to the underside of your bench could be the cause of sawdust falling in and clogging the working parts – the answer is in the patent:

The nut housing is usually provided with external flanges, lugs or the like by means of which the vice is secured to the under surface of a bench, the bench itself closing the housing. There is, however, often a passage from the bench surface to the housing between the back of the plate like portion of the fixed jaw and the bench mortise in which it is let and this passage, especially in the case of faulty or careless work in erecting the vice on the bench (GB409804 1923)

I leave it to the reader to decide how much of a problem was caused by all the careless vice fitting going on in the 1920s, but suffice to say Record go on to acknowledge (in the same patent) that the problem was already solved by their ‘screw and nut cover’ (see previous section) which they invented several years earlier.

The second improvement is more useful: In the design from the 1920s the half nut is hidden behind the casting of the rear carriage and is inaccessible once the vice is fixed to the bench.

The new design (below) has a separate metal housing that is attached to the rear carriage with two bolts and this means the the half nut can be removed for cleaning even after the vice has been fixed to the bench.

It is odd that Record did not include this feature in their patent application, since it is a genuine improvement. A possible explanation is that Woden had already described a detachable screw housing in their 1906 patent (GB25134), although they do not make any particular claims for it.

At this stage you will note that the ‘excluder plate’ is rendered even more redundant, since it is no longer necessary to get at the nut from the top.

Although there was nothing to prevent Record from producing the modified vices after the patent was filed at the end of 1932 the first mention I can find for these changes are in the 1935 catalogue[4]

There is a clear picture of the new housing in a catalogue from 1950:

Record pocket catalogue no 16 (1950), including a highlight (bottom) of the removable half-nut cage

My thought about the ‘sawdust excluder plate’ patent was that it was a slightly lame attempt by Record to extend their intellectual property protection over the vice given that their Registered Design was due to expire a few months later in 1933.

As mentioned above the Registered Design taken out by Record for their vice in 1918 ought to have expired no later than 1933, but the RD number continued to be shown on the vices literature after that point. Of course this would be explained if Record simply never got round to updating their catalogue etchings, but many surviving vices have both the RD number and the saw dust excluder plate which can be dated to 1932. Since it is unlikely all the vices with both the RD number and the ‘sawdust extractor plate’ were made between November 1932 and some point in 1933, this suggests that Record continued to use the face casting with the RD number beyond this date.

Thus the best we can say is that the ‘saw dust extractor’ model was introduced after 1932 and that early versions were available with both a Registered Design number stamped on the face and the transitional face design (shown below) where the space for the RD number is blank.

At some point after the design patent expired (1933) C & J Hampton – who I’ll just refer to as “Record” from now on, since they eventually decided to trade under this name for all their products – removed the design number from the front jaw casting:

transitional face design – the RD number is removed but the surrounding box is retained (~1933)

1940s

Version VI – new face design (~1940)

The final and arguably most refined version before a complete revamp in the 60s had a newly designed face and a very high quality finish:

this my one!

unfortunately it is not possible to date it very precisely. Given the transitional model is comparatively rare my guess is that at some point in the late 1930s Record launched this more attractive face design. The earliest catalogue I can find showing this casting is the Record no 16 pocket catalogue (1950).

By the 1940s Record had perfected their vice design and, having run out of ideas to improve it, filed no more patent applications for us to refer to. Unreliable as they may be, I think the only clues we can get at this distance of time will be from old adverts and catalogues but these are sadly few and far between for Record tools.

you can never have too many classic 52 1/2 vices

1960s

Version VII – the final Record 52 1/2 (1963)

the very last model created before the Record brand was sold to Irvin was launched in the 1960s. The changes made included:

- a new design for the front face casting

- a new square boss on the handle (previously oval)

- the part holding the sliding bars parallel at the far end of the vice is now made of sheet metal (previously cast iron)

- the removable steel ‘sawdust excluder plate’ in the rear carriage that covered the half-nut is gone and instead the casting is solid in this area

- the cast webs that braced the rear jaw and the horizontal face of the carriage are gone

- the two rear bolt holes in the carriage are now slotted

- the screw and nut cover is provided as standard with most of the QR vices in the range

Finally, they introduced a new model that included a dog in the front jaw.

On the cosmetic side, Record adopted a lighter blue colour and a new ‘record’ logo/sticker around this time and also came up with new codes to identify the various models:

- P= plain screw (i.e no quick release mechanism)

- C= combined vice and cramp for attaching/removing the vice

- E= Quick Release

- D= adjustable dog with QR (available as plainscrew too (‘DP’ although I think the castings were only marked D)

- no-postfix = lightweight plainscrew, ‘amateur ‘ and junior range

The new range was first announced in their 1963 catalogue

As you can see in the advert above, the new range is deemed by Record to be an improvement on the previous version – I leave it to the reader to decide how many of these changes really do improve the design!

Record merged with Ridgeway in the early 1970s and the new business continued to make versions of the 52 1/2, indeed the current owners of the Record brand (Irvin) still make a copy, although it is a pale imitation of the versions made in earlier decades.

you can see a summary of the timeline for this type of quick release vice here

The 52 ½ B

There is a version on the standard model that was made without a rear jaw, called the 52 1½ B. Unfortunately no documentation has been found explaining why Record thought this was a good idea. A possible explanation is that this design made it easier to fit on English workbenches that traditionally have an apron. They are rather uncommon, although all the examples I have seen have a Registered Design number on the face, suggesting they were made in the 20s and 30s.

Copies by Other Makers

The GB Patents and Designs Act 1907 granted Record a monopoly on their registered design for up to 15 years, so in theory from the end of 1933 other manufacturers would be free to copy the design. Since the design was so good it is not surprising that copies soon followed.

For instance, the Buck and Hickman 1935 catalogue introduces their own-brand (Toga) version of the vice and mentions that Parkinson have also made the same design available.

an early copy (Buck and Hickman 1935 catalogue)

Parkinson’s catalogue of 1940 (a reprint of their 1937 catalogue but with updated prices) shows they have dropped their old casts iron slider design and now only make the ‘Record’ version. They also licensed the “Screw and Nut Cover” from Record:

Countless companies have made copies of the design over the years. Some of the high quality versions in addition to Parkinson are: Toga (Bucks and Hickman), Rededa, Paramo, Marples, Woden. The modern copies (Irvin, Annant, York, Dawn etc), although functional, are made to a comparably low standard to keep the price down.

Appendix: How it works

A brilliantly simple design. Note this illustrates the slightly modified version of Parkinson’s original mechanism (introduced by Record in 1932 see Version IV above) – the spring in the original design was directly under the half nut.

References

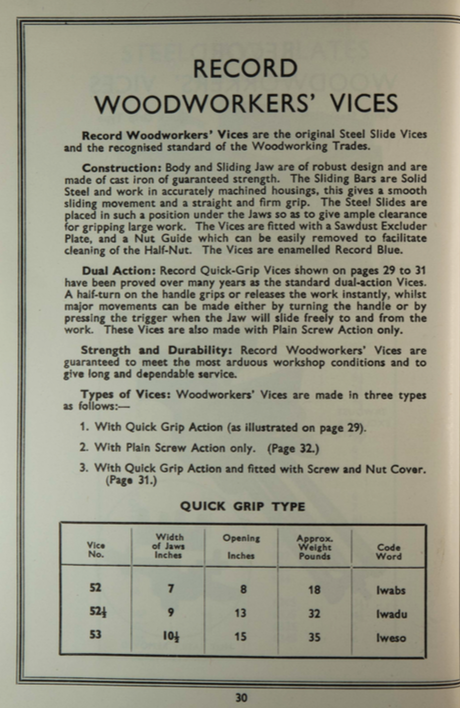

| 1 | incidentally, the Record woodworker’s vices were available 3 jaw widths: 7”, 9” and 10 1/2″. For reasons best known to themselves, C J Hampton named these with model numbers 52, 52 1/2 and 53 respectively. The 52 1/2 (9”) model is convenient size for lots of wood working jobs and was the most popular option. ⏎ |

| 2 | telegraphic addresses were memorable short-codes used to identify the recipients of a telegram. Some telegram addresses became so well known that organisations adopted them as their proper name e.g Interpol. ⏎ |

| 3 | c.f The Workbench Book p144. ⏎ | 4 | c.f 1935 pocket Record No 14 catalogue p95.⏎ |