Welcome to the first part of this potted history of the quick-release woodworking vice, a history that will culminate with the venerable and arguably never-bettered Record 52 1/2 vice.

We have much to thank a chap called Joseph Parkinson for. Parkinson did for vices what Leonard Bailey did for bench planes: he pioneered a design that become the de-facto standard and dominated the market for well over a century.

J W Parkinson and Son

David Fell’s father worked at the company founded by Parkinson and has created a web site that provides some background information on the business (J Parkinson and Son, Shipley, Yorks) and about the man himself, who was clearly an impressive fellow.

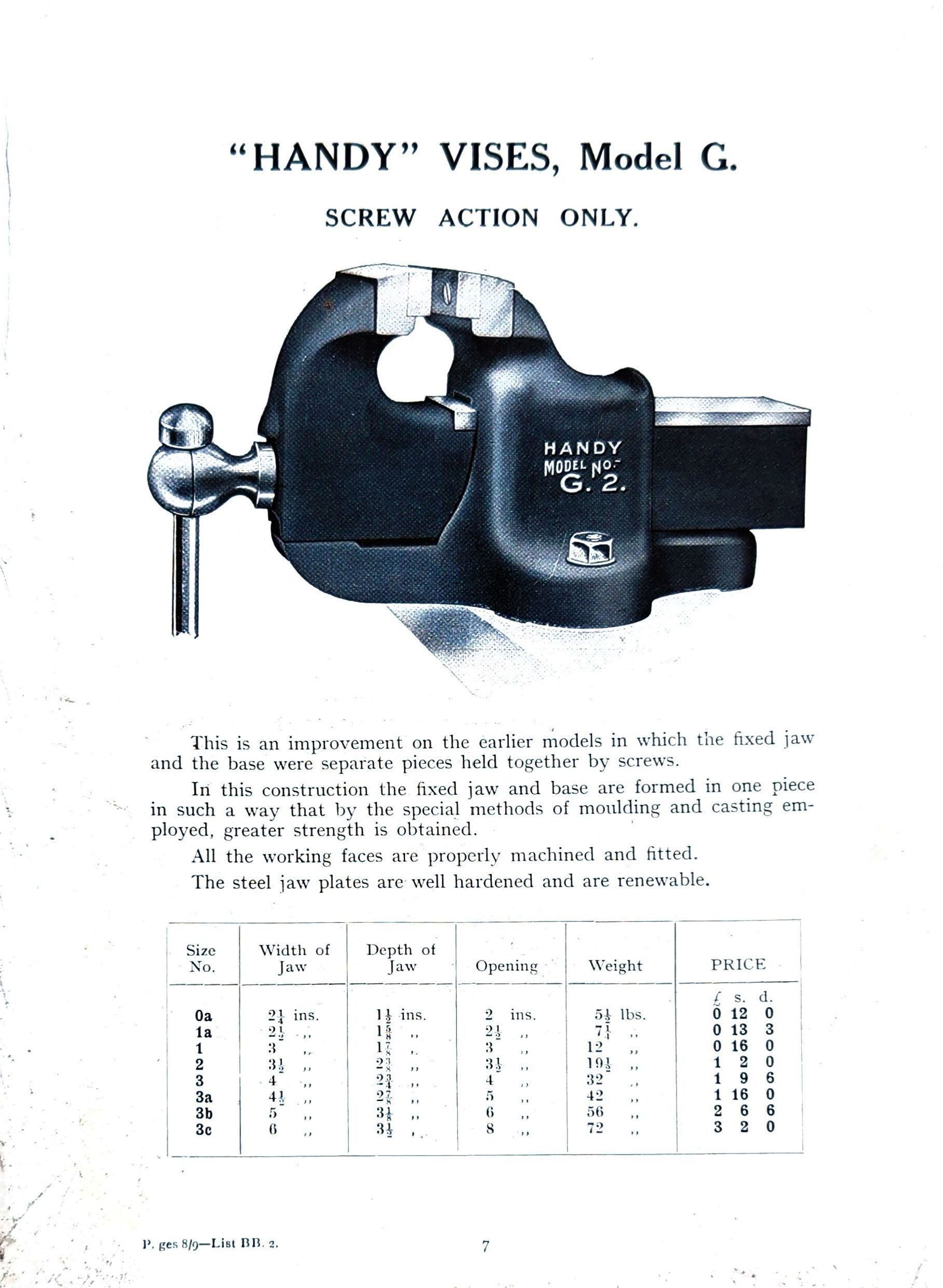

The company survived into the second half of the 20th century and, according to the account in a booklet produced to celebrate the centenary of its founding, Parkinson invented his quick release vice in 1884, having come a cropper in his dealings with a customer who had copied the design of his ‘handy’ line of vices and then started up in competition with him.

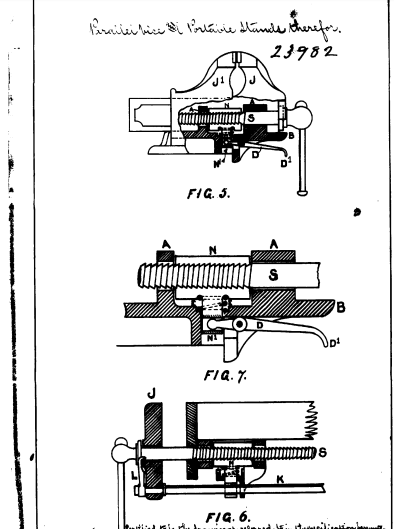

Having had his fingers burned once before he decided to get protection on his new invention and registered patents in multiple countries during the next year or so. You can see a copy of the US patent (1886) here: US361445

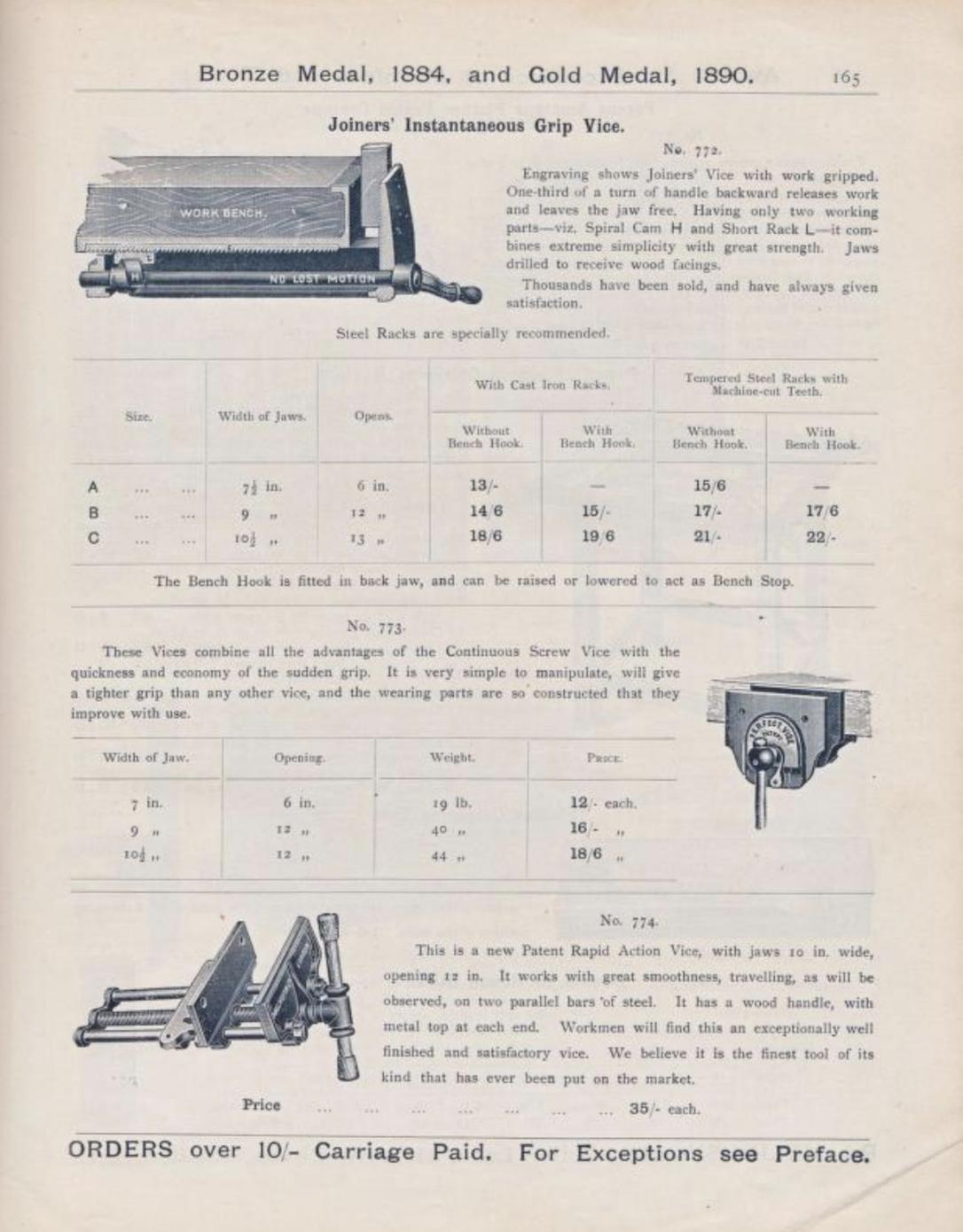

…and this is a picture of the workings taken from the Canadian patent (this Canadian patent shows a picture of the joiners vice, omitted from the drawings in the US application)

the joiners vice is shown in illustration at the bottom

Unfortunately the text of the Canadian patent is hand written and not very well scanned which makes it almost illegible, so we have to go just on the drawing for details.

c.f Fig 6 above for a sketch of the woodworker’s vice: there is a spring loaded flat bar (k) which engages with a groove in the base of a half nut (N). The bar is attached to a lever (L) next to the vice handle and when squeezed the lever causes the flat bar to pivot downwards, taking the nut with it and disengaging it from the screw. In this position the vice moves freely back and forwards.

Although not completely clear in the picture, it is almost certain that the spring that holds the bar/nut in the engaged position for the woodworker’s vice is directly under the half nut, rather than next to the trigger (which is the familiar arrangement today). C&J Hampton (Record) – who copied Parkinson’s QR mechanism – used the same arrangement up until the early 1930s:

old C&J Hampton (aka Record) vice – you can just see the spring through the hole in the under carriage

C&J Hampton eventually found a better solution and moved the spring to the inside face of the vice. This meant that the half-nut used in the QR mechanism could be housed in a removable casing so it could be extracted for

cleaning without first having to remove the vice from the bench.

In turn Parkinson adopted this improvement in their vices:

Having invented an effective quick-release mechanism Parkinson was able to use a buttress thread for the screw. These threads apply a strong force in one direction at the expense of their effectiveness in the reverse direction (not a problem w

hen the vice can be opened without the screw using the quick-release lever). See, for example, toothpaste tops for an example of this type of thread:

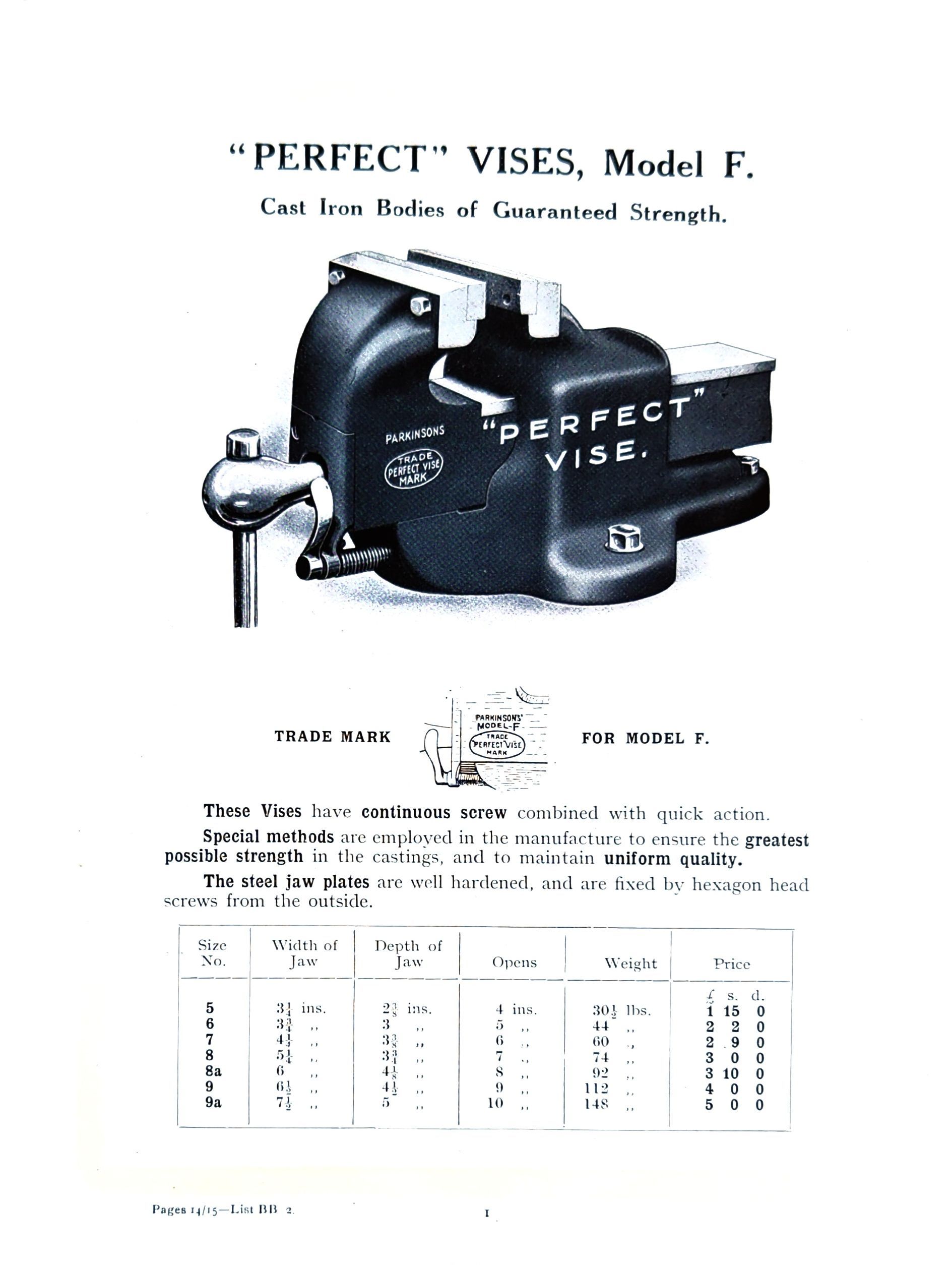

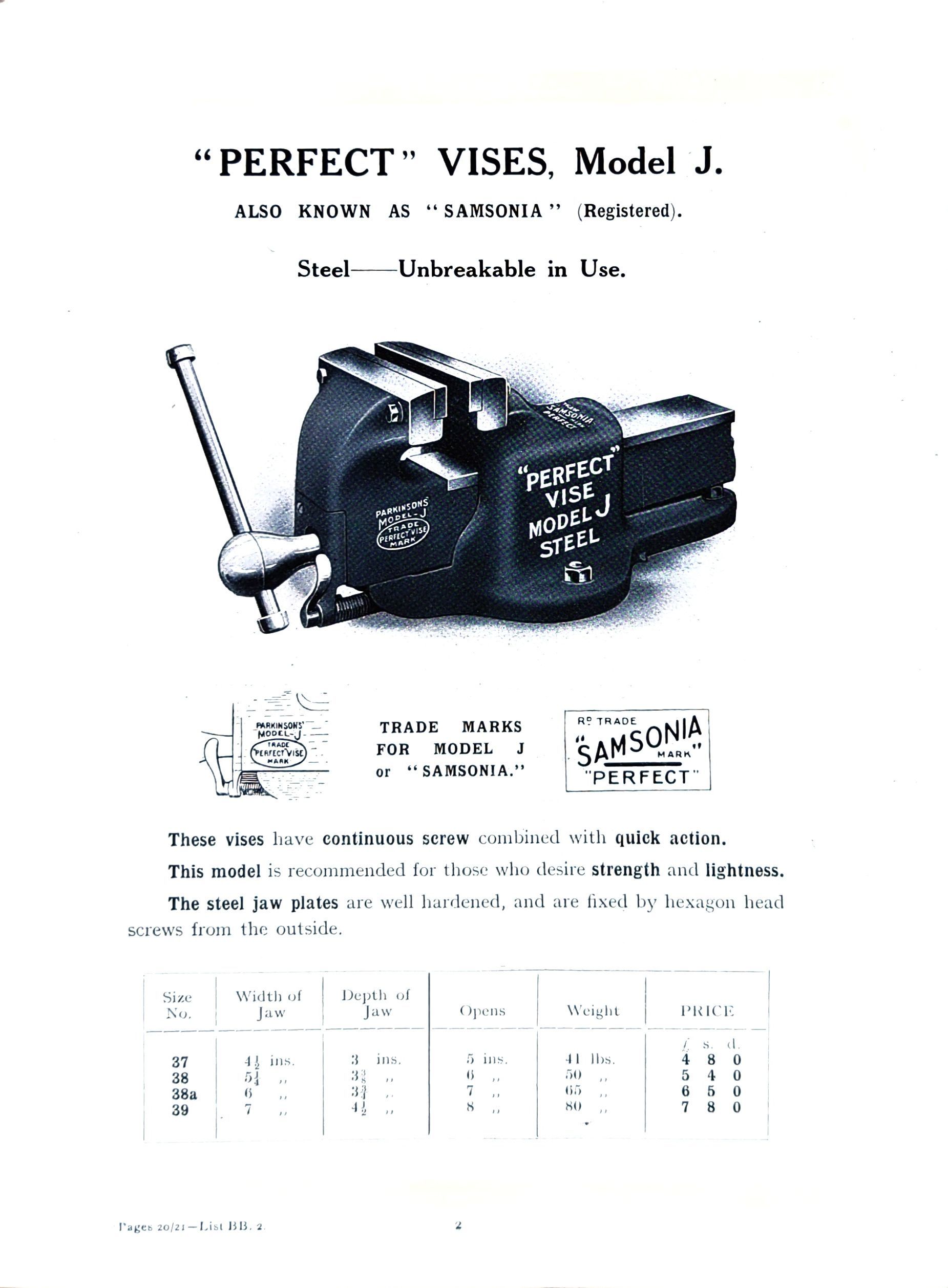

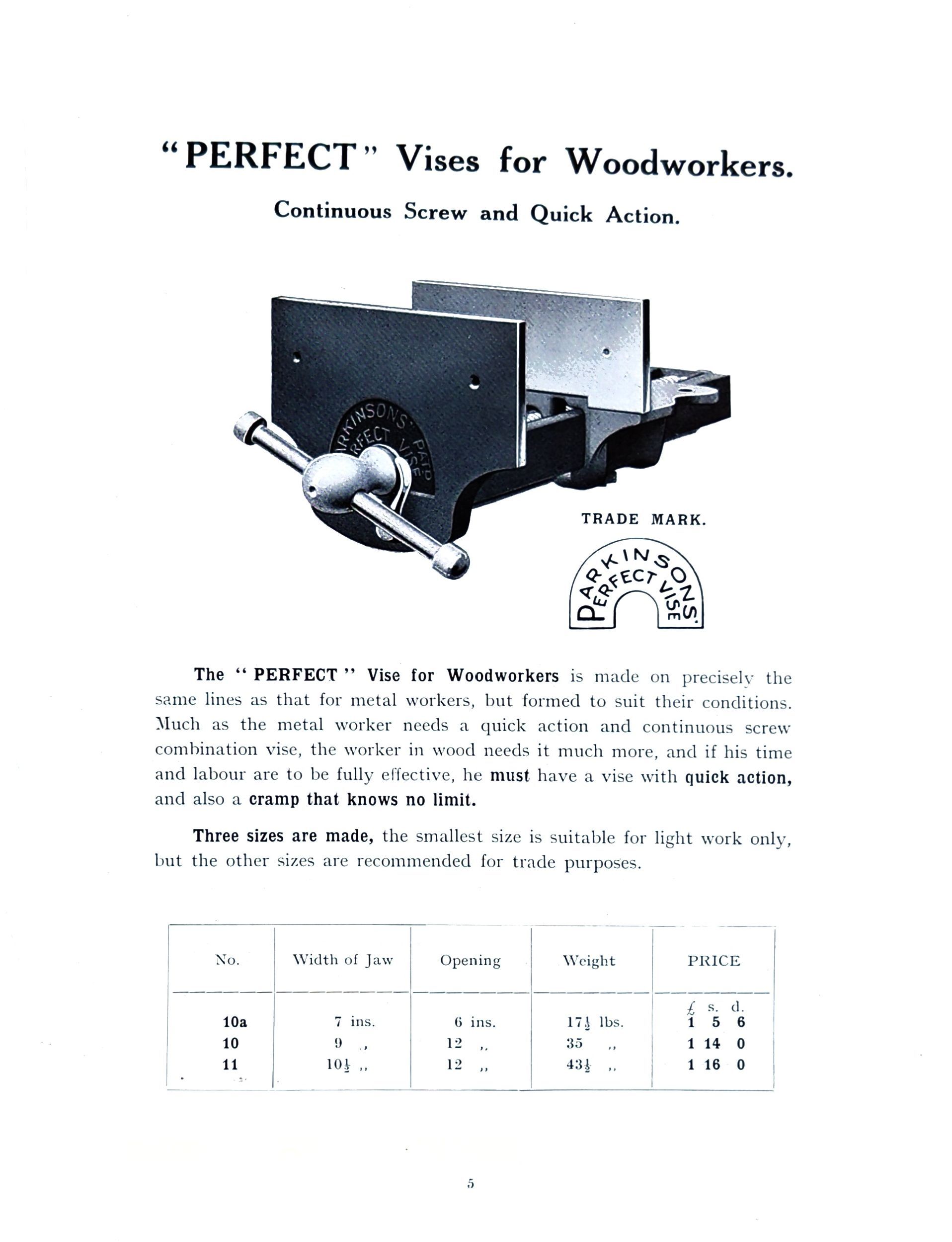

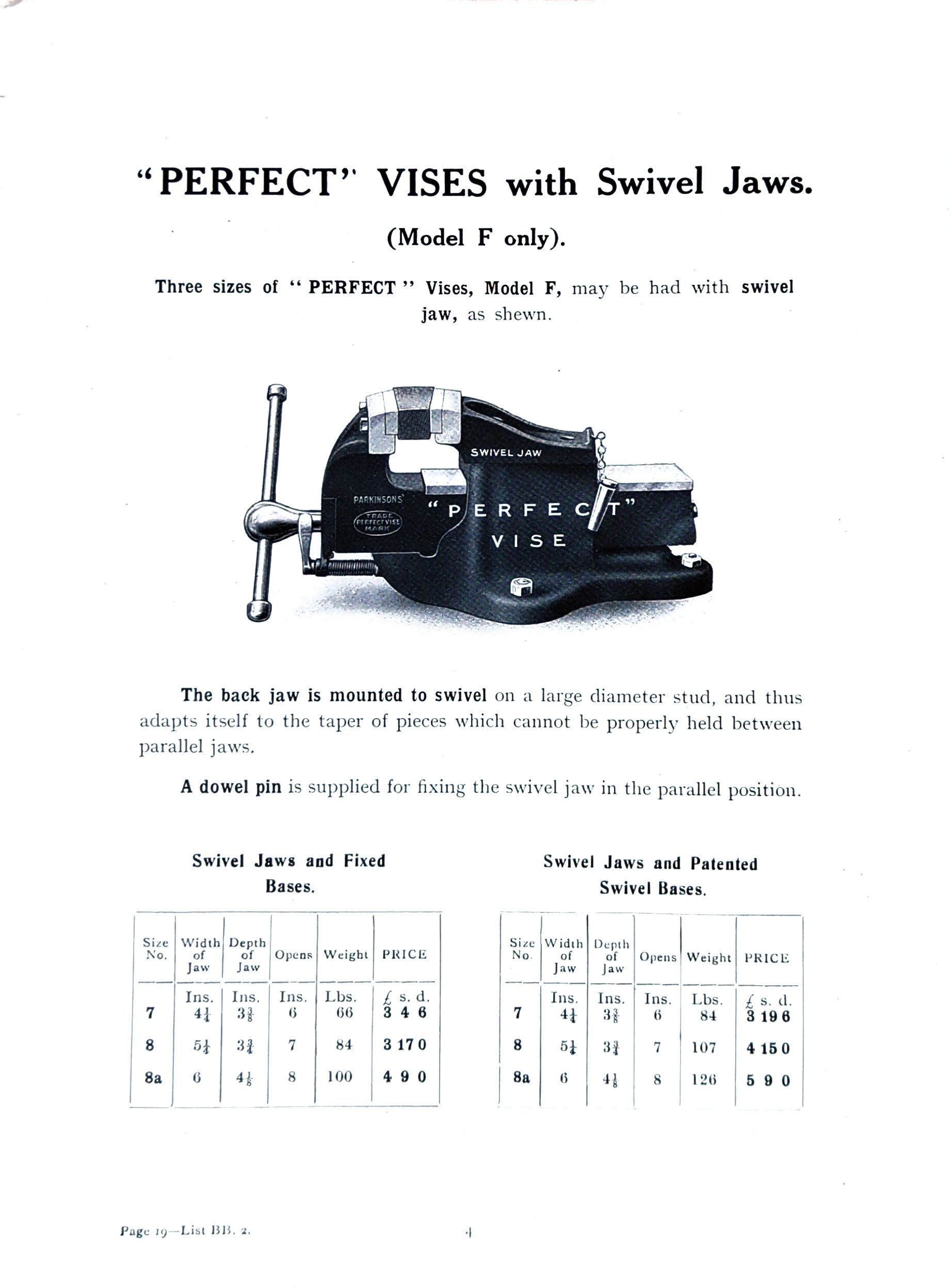

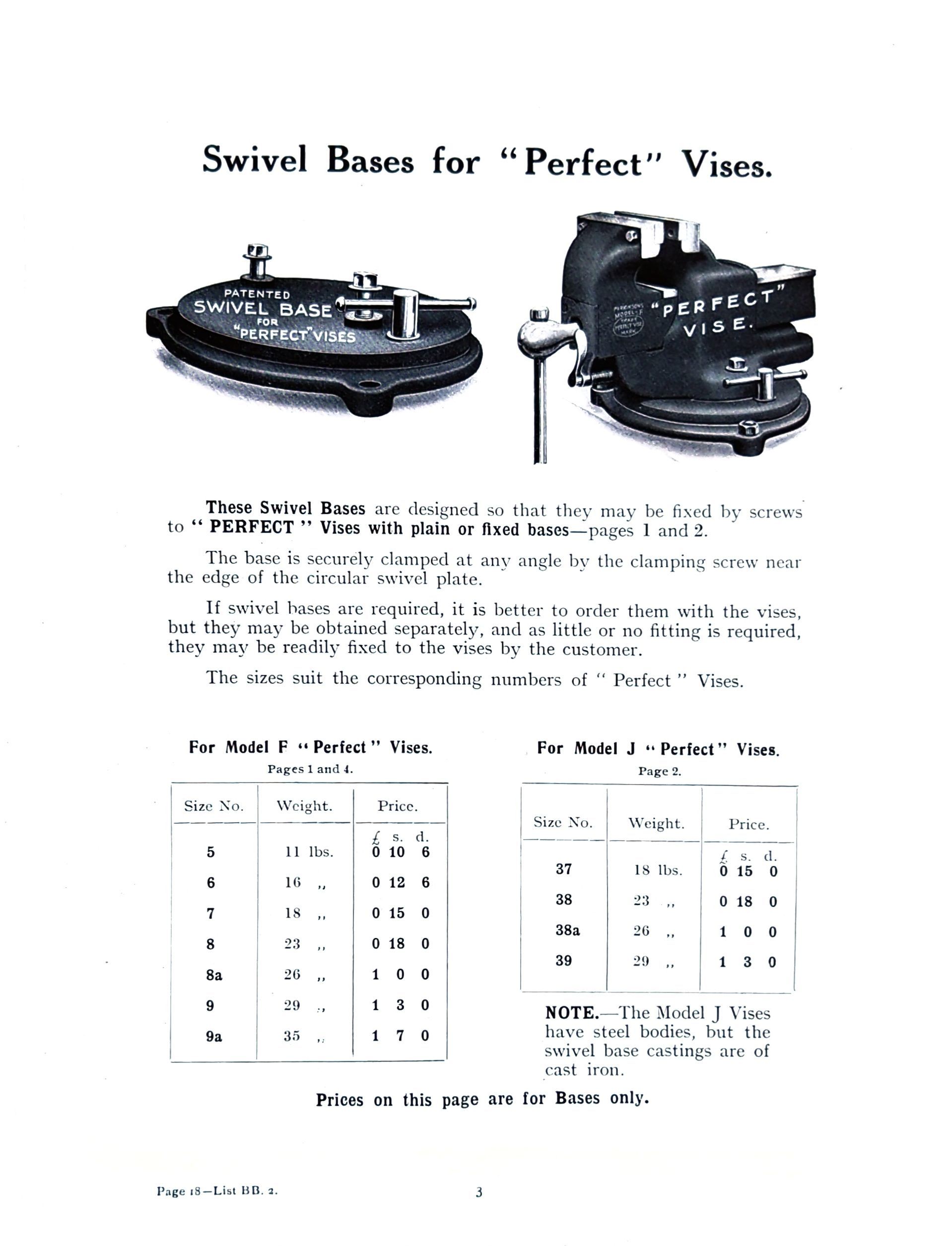

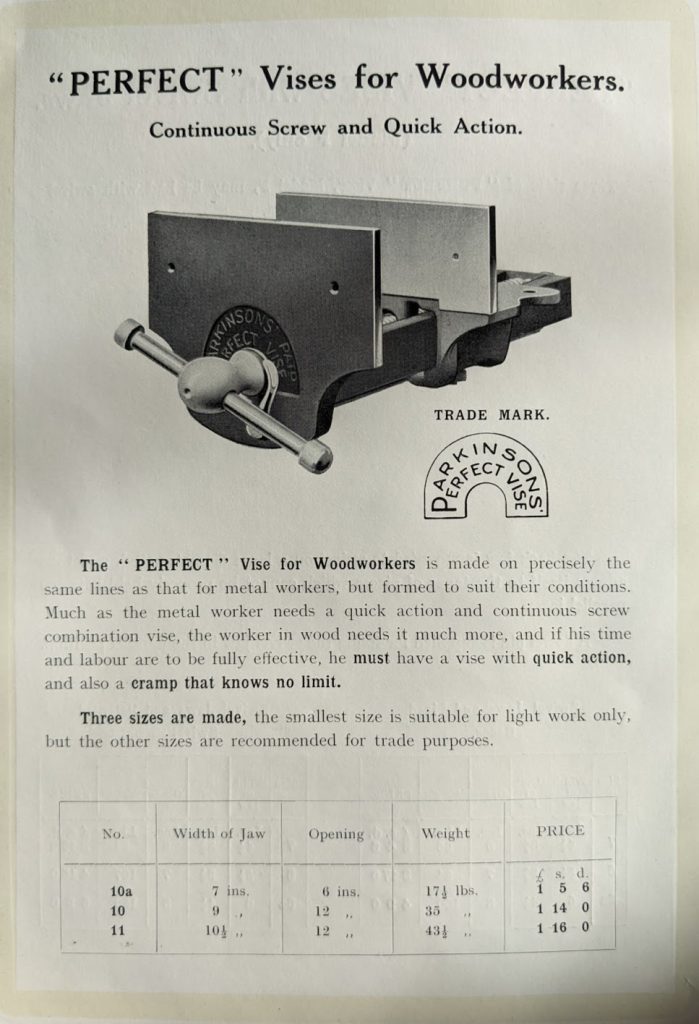

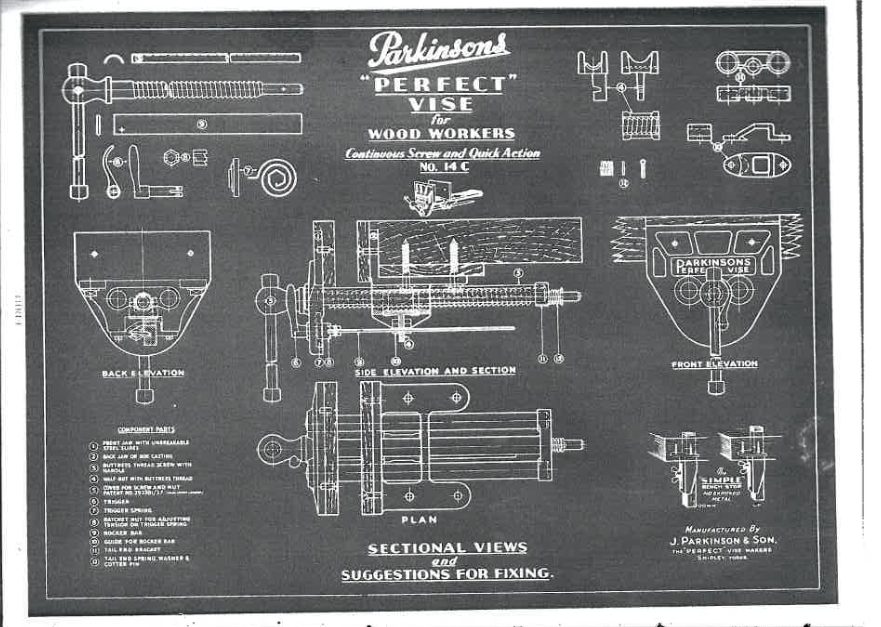

Parkinson called the new range of vices the ‘Patent Perfect’ range, and in the terminology of the day it was an ‘instantaneous grip vice’ – the earliest reference to the term we have settled on in recent times ( ‘quick release’) was about 15 years later, in a patent filed by an American.

Parkinson vice catalogue (1920s)

The vices were clearly successful (and well built), and frequently turn up for sale in working condition today. An early model is shown above. Note that the vice runs on parallel cast ‘sliders’ rather than the round steel guides in later vices from Record et al and also the unconventional (for the UK) spelling of ‘vise’ – no doubt to contrast this range with his older range of vices.

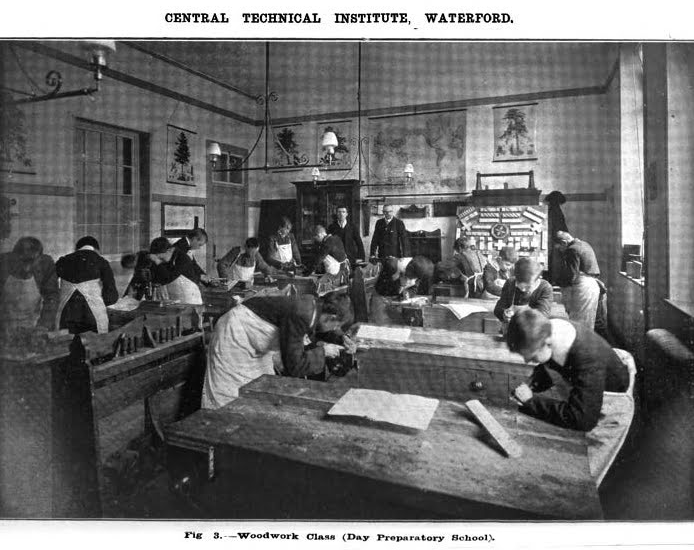

There are a number of references to Parky vices in books aimed at headmasters and teachers, and perhaps their adoption in classrooms helps explain why there are so many still around. Mind you, they also had a decent production run: the distinctive design shown above, with the unadorned front jaw and cast steel sliders, was made at least until 1930 (more on that later).

Here are some youths enjoying their Parky vices at a school in Ireland (1907) where 10 were installed

Type study - mark I (1884)

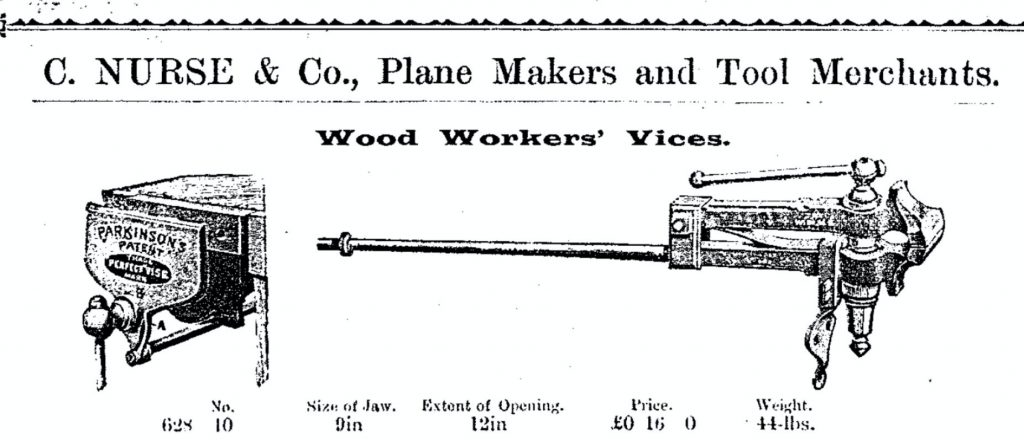

We know the Parkinson perfect instantaneous grip was made from 1884/5 onwards, the earliest picture I can find of the woodworkers’ model is from the Charles Nurse 1891 catalogue (this catalogue is available – along with other catalogues – from taths.org) and shows a design I have not seen elsewhere:

Parkinson wood workers’ vice (left)

… this appears to be the very first model (1885 onwards).

mark II (~1905)

The ‘mark II’ model has cast iron sliders and a distinctive front face design with “Parkinson’s Patent Perfect Vise” cast in a semicircle around the handle can be seen in this 1905 catalogue by Melhuish:

Thus the best we can say is about Mark II is is it was introduced before 1905.

mark III (~1930)

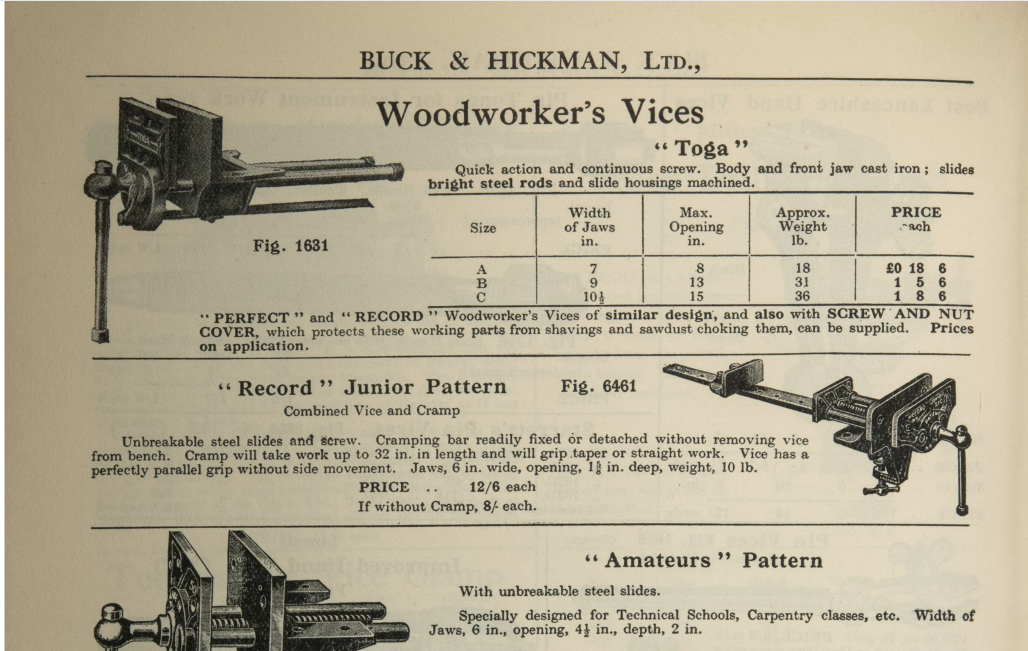

The catalogue below shows the Mark II being sold alongside the Record pattern that would eventually displace it (note that by this time Record had adopted steel rods – an improvement over fragile cast iron sliders):

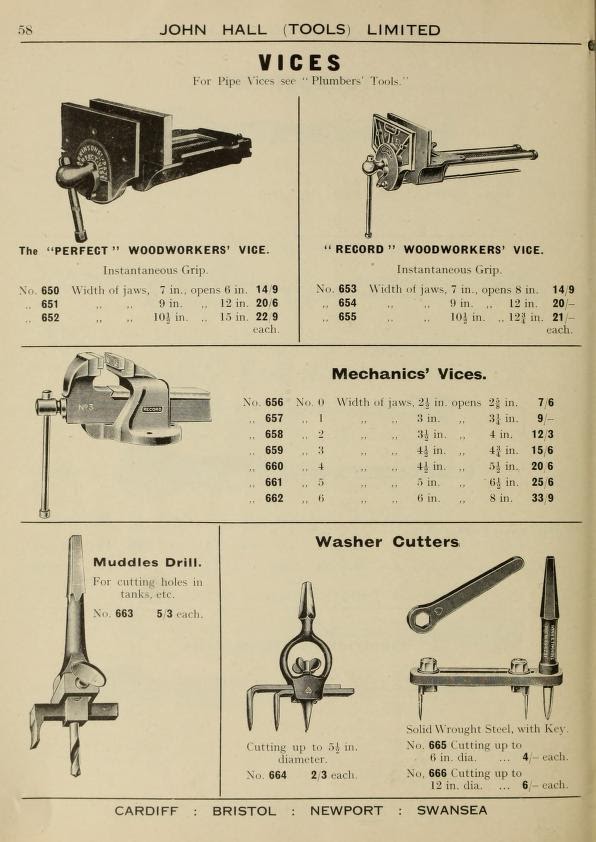

John Hall catalogue ~1927 (top left)

The 1930s catalogue entries below show the mark II Parkinson but (this time with two screw holes rather than three). It is likely that this is one of the final outings for the old Parky ‘steel slider’ design:

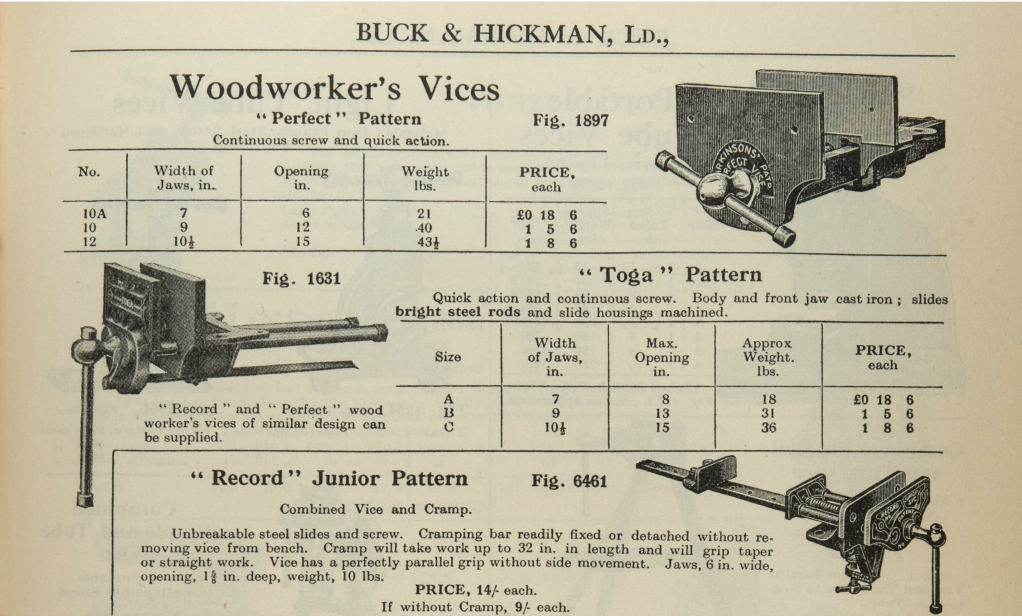

Buck & Hickman 1930 / Parkinson Vises – pamphlet (~1930)

As you can see, Record undercut the price of the older Parkinson mark II vice and, since theirs was an improved design, it is likely that they would have quickly eroded Parky’s sales. Indeed, by 1930 much of UK QR vice production – and there were numerous competing makers – had switched to using a Record-like design.

We’ll call the mark III version of Parky’s range the ‘Record Pattern’ – as we can see from the B&H catalogue above, this version was introduced alongside the traditional Mark II cast steel slider version.

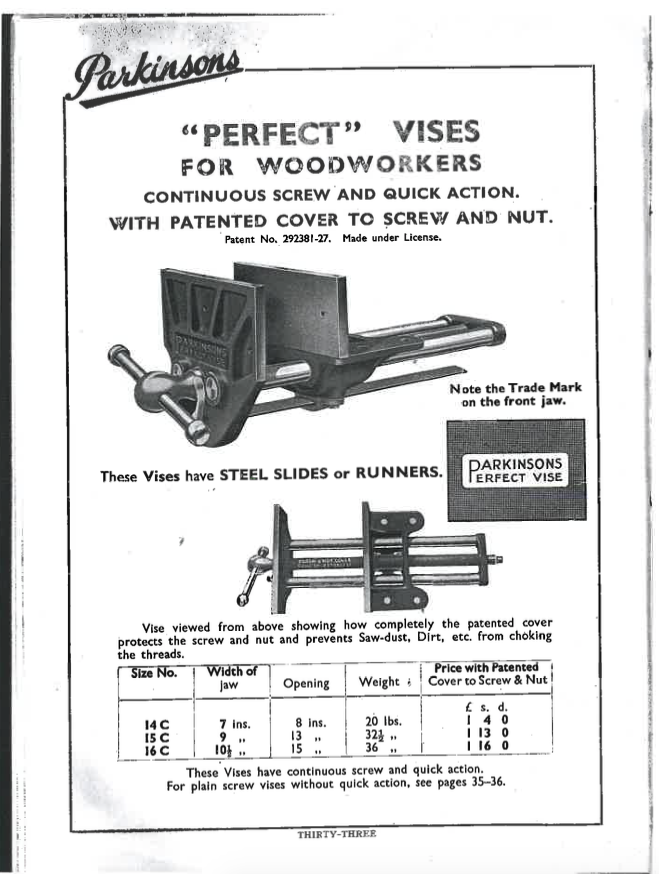

This version has a newly designed front face, as is shown in their 1937 catalogue. (the scanned version was published in 1940, but a cover note explains it is a reprint of their 1937 edition). Note that the tables have truly turned and at this stage Parkinson are making an exact copy of their competitor’s model, going as far as licensing the ‘screw and nut cover’ idea from Record:

1940 catalogue

By 1935, at least according to the Buck & Hickman’s catalogue below, the Mark II pattern was no longer available.

B&H 1935

Timeline

So in summary, the timeline seems to be roughly:

- mark I: 1884/5 initial quick-release model introduced – see Charles Nurse catalogue above

- mark II (introduced between 1891-1905) new design of front jaw (see photo of vice painted in red above).

- mark III (~1930) – Record Pattern introduced (steel sliders and newly designed front jaw – see advert immediately above). This was initially sold alongside the mark II until the earlier model was discontinued in the second half of the 1930s)

Eventually Joseph Parkinson’s quick-release mechanism would become a standard fixture in woodworking benches the world over, but he was not without competition. Two notable examples are The ‘Syers’ standard instantaneous grip vice and the ‘Riley’ instantaneous grip vice. Before we get to those we will take a brief detour into US made vices in the next post.