Timing

The cam to crank timing is initially set when you assemble the engine. Timing refers to the regulation of the parts of a mechanism to ensure it works as designed. In this context it a reference to the mechanism by which the crank turns the camshaft and the valves in the engine are made to open and close at the right time.

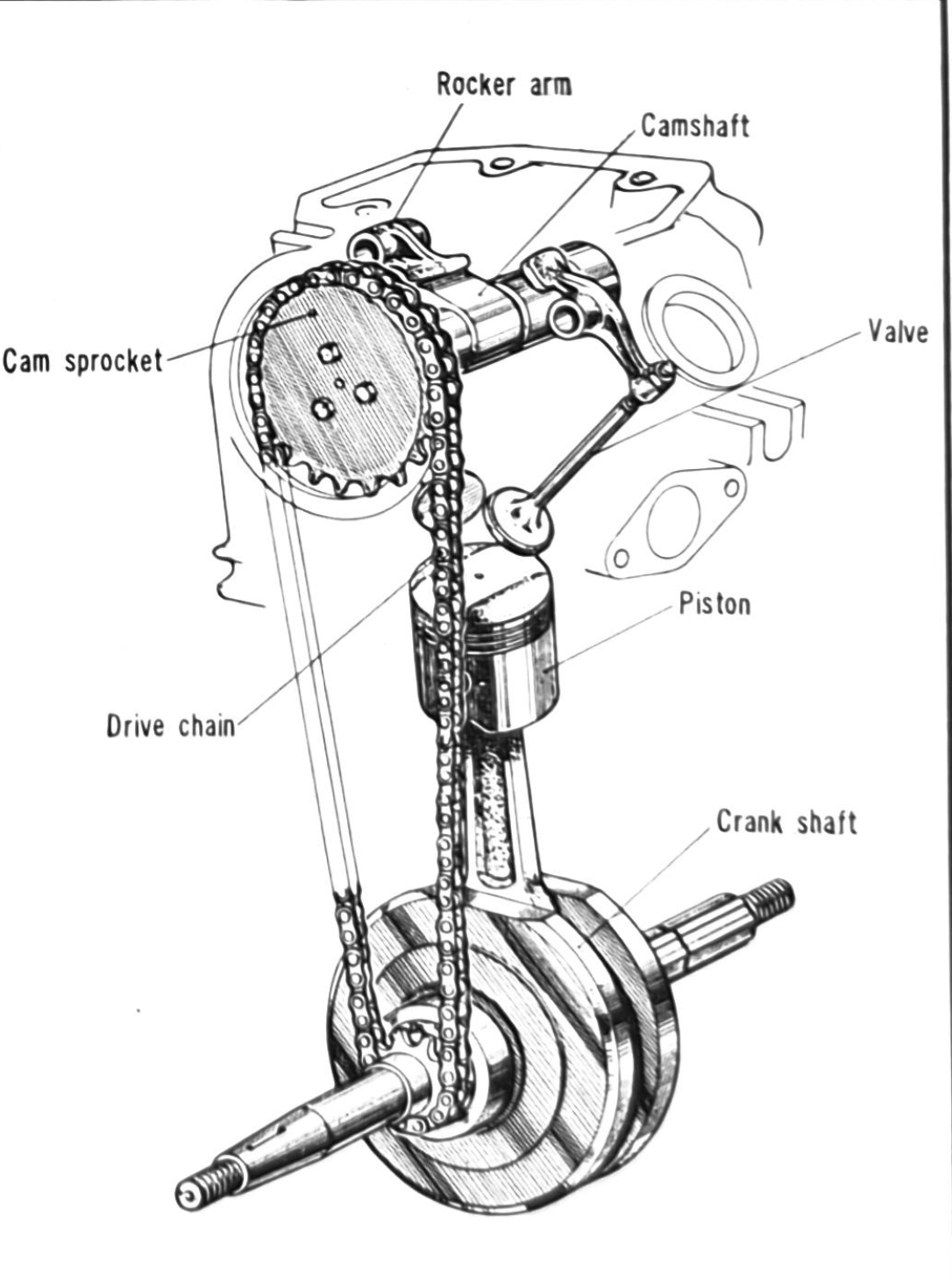

The c90 is a very simple engine with a single cylinder and two valves (an exhaust valve and an intake valve). You can see the parts below:

As you can see above, a chain is used to connect the crankshaft sprocket and the sprocket on the camshaft (called the timing sprocket). There are twice as many teeth on the camshaft sprocket than timing sprocket which means the camshaft turns once for every two rotations of the engine.

As the engine turns, the two lobes on the camshaft lift the rocker arms mounted in the cylinder head causing them to push down on their respective valves so that they open in sequence.

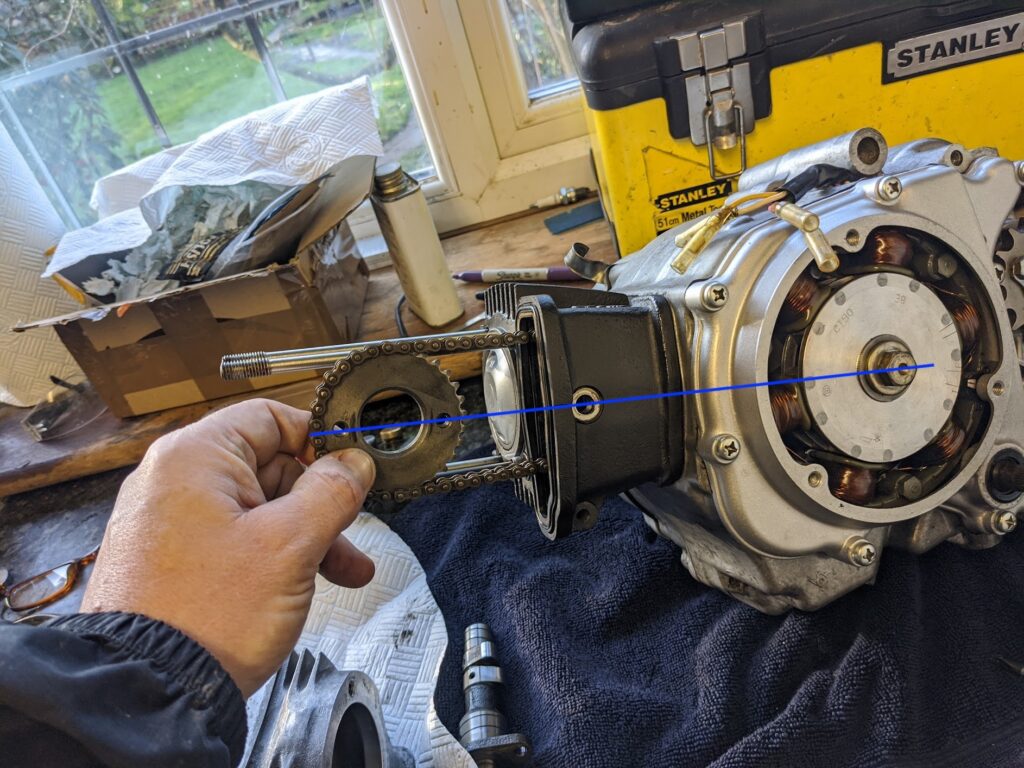

The cam shaft (left) can be extracted after you remove the left hand cover, points and camshaft sprocket on the cylinder head

Valve sequence

As noted above, the camshaft sprocket turns once for every two revolutions of the crankshaft. During the first revolution of the crankshaft the intake valve opens and the descending piston draws in air and fuel into the combustion chamber, then – as the piston ascends – the valve closes and the mixture is compressed. As the piston reaches the top of the cylinder the mixture is ignited, forcing the piston downwards and starting the second revolution of the crankshaft. Finally as the piston returns upwards, the exhaust valve opens so the burnt fuel can be expelled. This sequence is easy to recall with the mnemonic “suck, squeeze, bang, blow”.

This excellent video shows these parts in action:

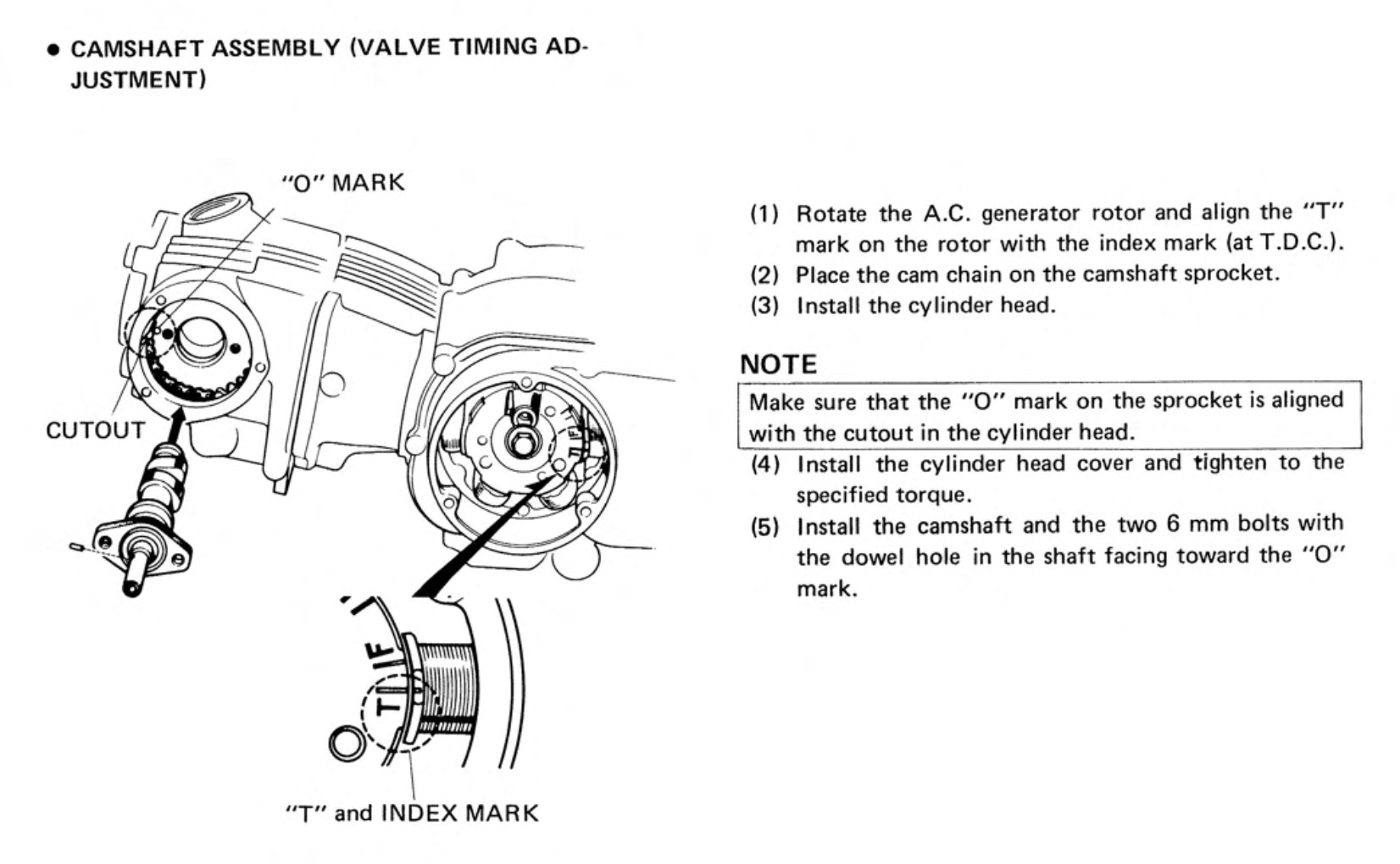

Setting cam to crank timing

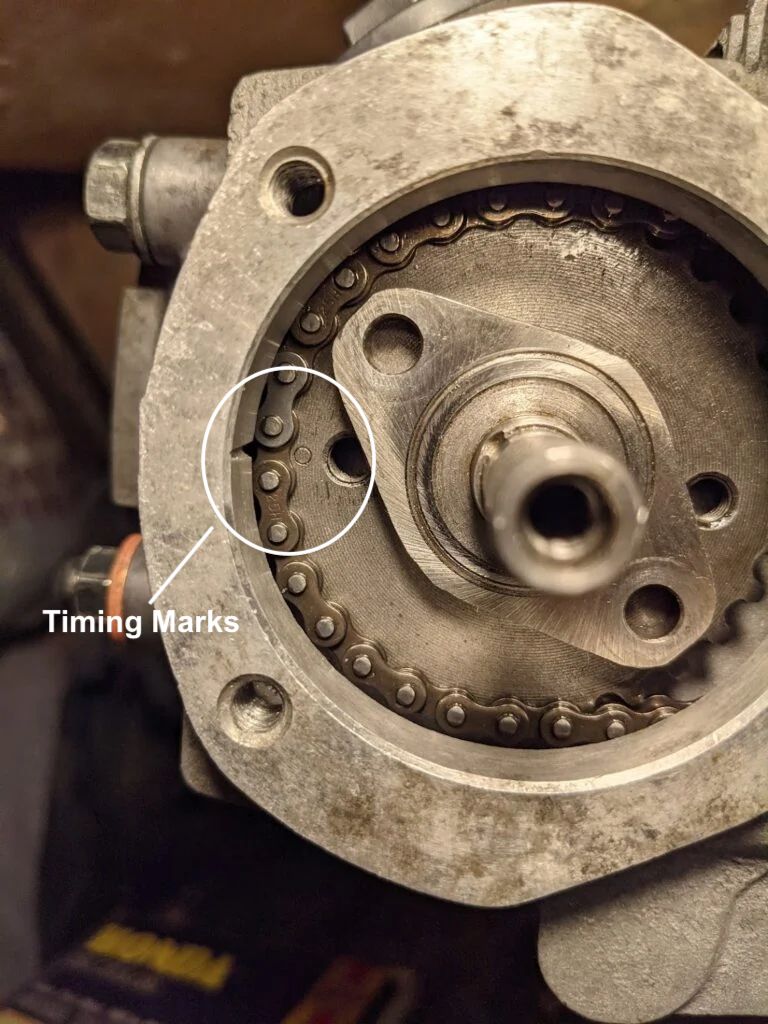

The cam to crank timing is set when you assemble the engine. You must align the timing mark on the cam sprocket (a small “o”) with an index notched on the cylinder head. This picture shows the timing marks in the 89cc engine from a late 1970s 6v C90 (the same engine was used on many models including the CT90):

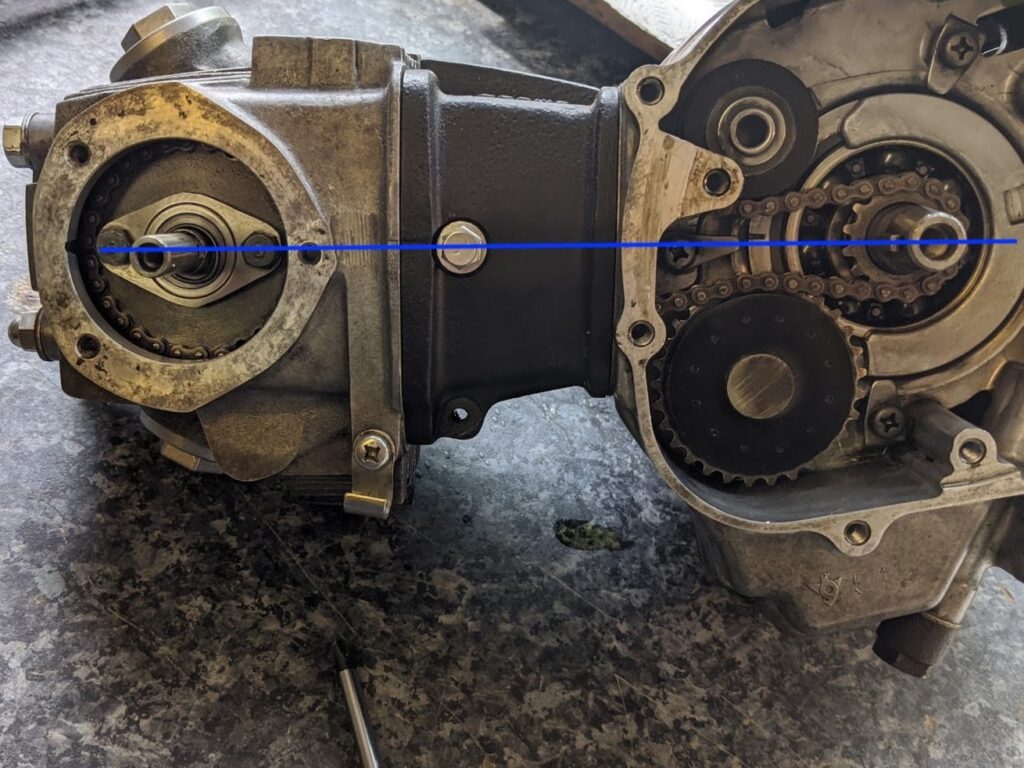

This must be done when the piston is at the top of its stroke. In this position the woodruff key on the crankshaft will be on the cylinder centreline and pointing in the direction of the cylinder head:

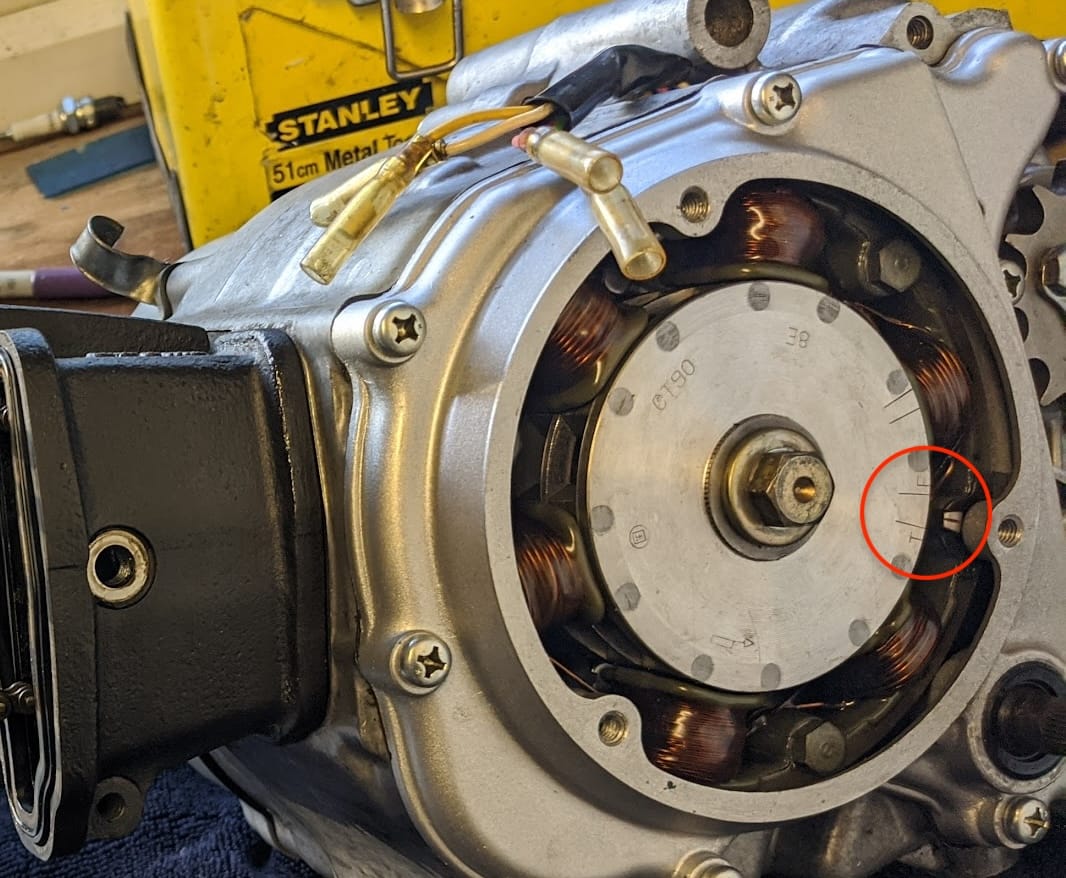

If the rotor and stator are already installed, the piston is at the top of its stroke when the the “T” (TDC) mark on the rotor is aligned with the pointer on the stator

Honda made the holes on the cam and sprocket slightly off centre to prevent the cam being fitted incorrectly. In the timed position the hole in the cam shaft for the dowel that locates the spark advancer will be pointing towards the notch in the cylinder head.

When you are all done the engine is at top dead centre on the compression stroke (ie both valves are shut).

Out of time

That’s all there is to it, but this is still important to know since the timing between cam and crank determines the position of the open valves in relation to the piston and – if the timing is badly wrong – they might collide.

If you aren’t paying attention it is not difficult to get the timing out by one tooth on the cam sprocket: if the error results in the sprocket being rotated clockwise relative to the crank then the the valve timing is retarded (which is to say, the intake valve and exhaust valves will open later), and vice versa when the sprocket is rotated anti-clockwise.

If the crank to cam timing is incorrect, assuming the engine can run at all, performance is effected because the piston will be out of position when the valves are opening and closing and - because the contact breaker position is indexed to the camshaft in this model - the ignition timing will be off. Despite this, these engines will apparently still run when the cam to crank timing is 'out by a tooth'.

Assembly

the cam only goes in to the head one way (note the small index pin on the cam is facing towards the top of the cylinder head)

The next component to consider in cam chain which, if incorrectly maintained, can also cause timing problems: