Some Festool vacuum owners had issues with the original Ultimate Dust Deputy (UDD), apparently because it caused a static build up that discharged through the vac damaging its motherboard in the process. Do you need to be concerned about the same thing happening to your vac?

Static electricity and the original Dust Deputy

You can read Oneida’s official description of the issue and how they corrected it here (also note the comment about Festool’s warranty)

What Oneida say is:

The inlet of Festool® dust extractors incorporates a connection to the earth ground to provide a safe discharge pathway for static electricity that may be generated when wood dust moves through hose or plastic parts. This grounded inlet works in conjunction with anti-static hoses. Oneida wants to make certain that our Ultimate Dust Deputy® customers understand that there is a grounding pathway that must be maintained. Oneida has always used static dissipating components in the Ultimate Dust Deputy® but to make absolutely certain that this path to ground is maintained at the highest level the UDD uses static conductive components. “

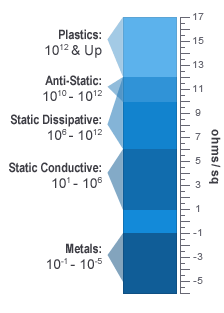

What does this all mean? And what does it mean for those of us with cheaper vacs that do not have a grounded inlet? The first thing is to understand the jargon, and there is a helpful summary on Oneida’s web site. Oneida include a scale for the relative conductivity of materials, from insulators at the top to conductors at the bottom:

The chart shows that dissipative materials allow charges to flow but do so more slowly than conductive materials. Oneida say the upgrade from dissipative to conductive materials in the new model allow any static to discharge via the grounded inlet in the Festool CTL vacs (which is in turn is connected to the earth for your domestic wiring, via the plug):

What went wrong?

A likely explanation is that the static created by the large amount of contact between spinning wood dust and the plastic cyclone (see previous post for an explanation) caused a charge to build up in the cyclone that the materials in the original Ultimate Dust Deputy could not dissipate quickly enough, and this allowed a large potential voltage to accumulate.

Any static accumulating that is not dissipated through the air will have to go somewhere and it is possible that the voltage – if it reached high enough level – might travel across the air in the inlet hose (which will have been slightly conductive due to the dust particles travelling through it) and into the electronics of the vac.

If this is correct then in theory the same thing could happen in my set-up since the vac inlet on the small CTL SYS vac is not earthed and there s no way for the the static to drain other than through the air, through the operator (me) or through the vac (putting the electrics at risk).

I suppose the fact the new model is made of conductive materials reduces the risk of a large discharge since any charge will be distributed over the surface area of the Dust Deputy and the hoses, creating more opportunities for the charge to dissipate to air, but nonetheless I plan to follow Oneida’s guidance and have found an alternative way to ground it.

Is static electricity likely to damage my vac?

Festool do not appear to think so – they sell vacuums with either ‘antistatic’ or normal hoses (the antistatic hoses have a high carbon content) Here is what they say about the antistatic versions:

“Festool’s Antistatic hose design helps you work cleaner by preventing dust from accumulating on the exterior of the hose. It helps you work more safely by preventing static discharge or shocks. And you’ll work more efficiently with a system that prevents clogging due to particulate buildup inside the hose”

There is no mention of protecting the vac from damage, and the fact they supply non-antistatic for use with their vacuums suggests the static generated by a normal vacuum is nothing more than a nuisance. More detail on this thrilling topic here!