One of the first things I did when trying to get my old Honda C90 to run was to clean the carburettor, having read that it might have become clogged up with old fuel while it was in storage. I did eventually get it to run but it didn’t idle well and was hard to start, but I had no idea why. Like much of the maintenance work I did at the time I'd been blindly following instructions without really understanding what I was doing or why it was necessary, so there was not much chance of finding out if the carburettor was still the cause of these problems.

Since then I've revisited all the mechanical work I did originally in an attempt to properly understand what all the parts do and why the work was needed. Here is what I learned on the way, starting with the carburettor.

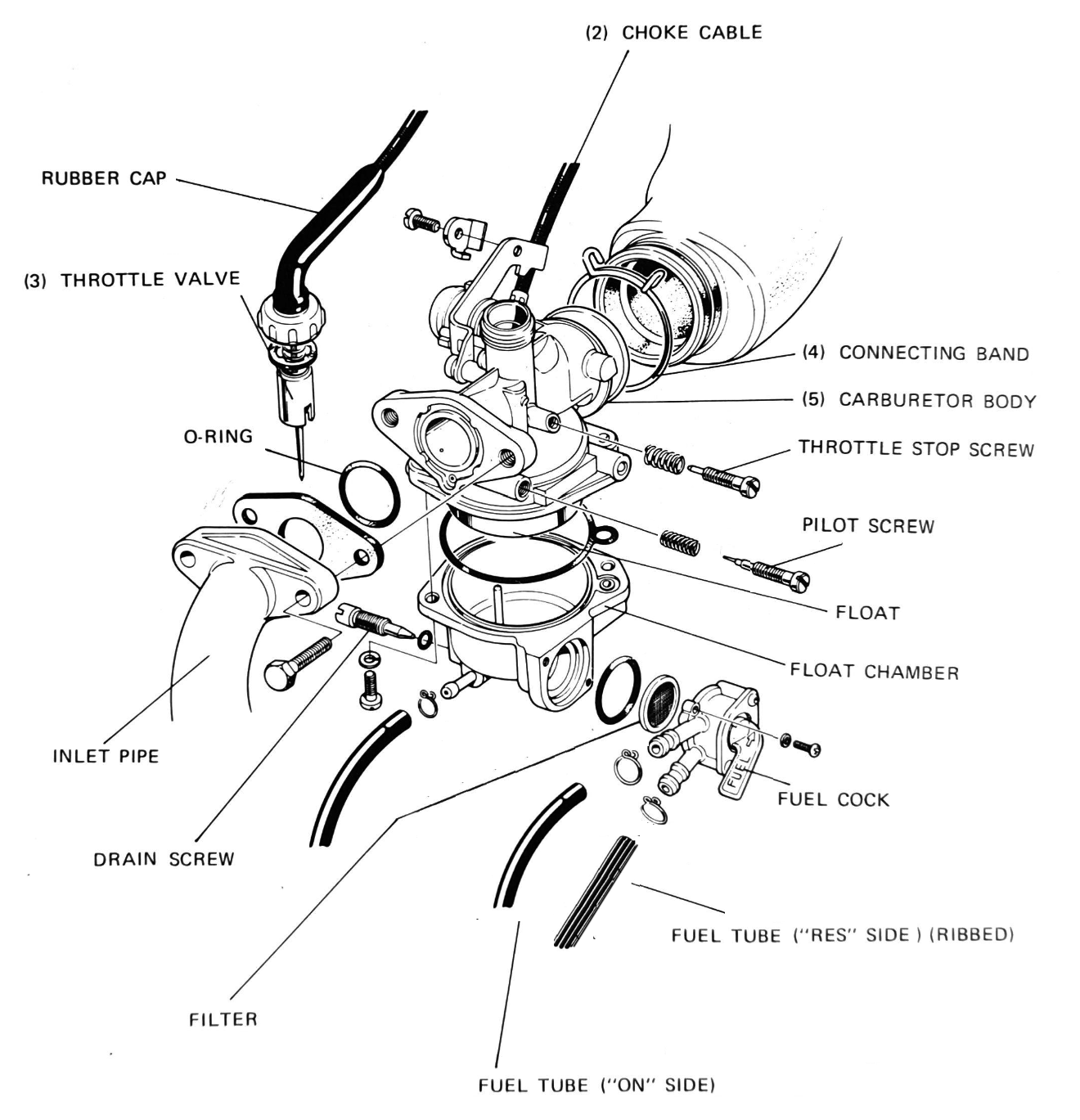

Here are the c90z carburettor components:

schematic of c90z carburettor (left) and dismantled parts (right)

Terminology

The function of the carburettor is to mix fuel and air in the right proportions before it is ignited in the cylinder. The boffins tell us that there is an an ideal air/fuel mixture – known as a stoichiometric mixture – where there is just enough oxygen present in the mixture to burn up all of the fuel.

Mixtures where there is insufficient oxygen present to burn all the fuel are said to be rich. Where there is more oxygen than necessary the mixture is said to be lean[1].

A lean mixture tends to increase combustion temperatures and this can lead to overheating and burned valves. If running a rich mixture then some fuel in the cylinder is unburned and this reduces power and wastes fuel.

The carburettor is designed to control the mix of air and fuel so that it burns as completely as possible - whatever the engine speed - but does not create a lean condition where the piston, cylinder and cylinder head might get too hot.

How it works

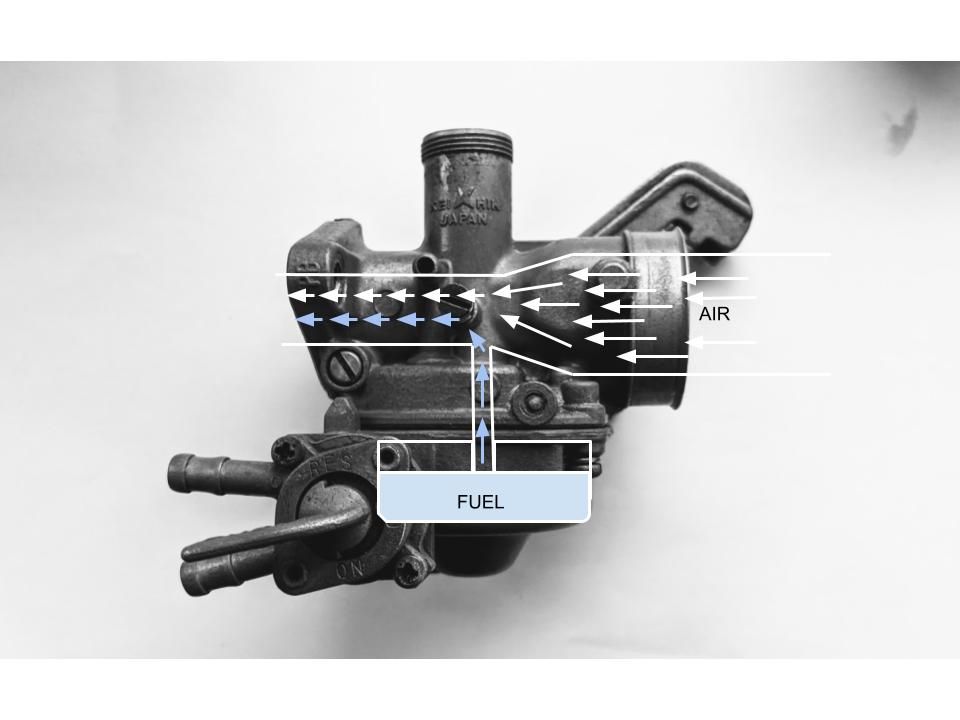

As the piston in the engine moves downwards, air rushes into the carburettor and is forced through a narrow constriction in the carburettor bore (called a venturi). This causes the air to speed up and the pressure in this section to be reduced.

The fuel, which is held in a bowl at the base of the carburettor, is pushed by atmospheric pressure into the low pressure area in the venturi where it mixes with the air on the way through to the cylinder. The air fuel mixture in the cylinder is then compressed by the now ascending piston and ignited, restarting the cycle and driving the engine.

That’s it! This is essentially all the carburettor does. But what is going on? With apologies in advance to any scientists who might be reading this, here is a rough explanation:

Venturi effect

The carburettor works because of the Venturi effect (named after Giovanni Venturi). This is the name for the reduction in pressure that occurs when a fluid (i.e. a liquid or a gas) flows through a constricted section in a pipe.

As the air passes through the narrowest point it has to speed up to get the same volume of air through the narrower gap and, as it accelerates, the pressure drops.

The relationship between fluid velocity and pressure was first observed by 18th C scientist called Daniel Bernoulli. Here is a proper scientific explanation for those that might be interested.

Luckily we don’t need to understand the mathematical relationship between air speed and pressure, we just need to know that fast moving air has lower pressure.

One way to think about what is happening is that the air is being stretched so that it contains fewer molecules per unit of volume and is therefore less dense, creating less pressure.

The tremendous video below uses a home made transparent carburettor so you can see the venturi effect in action:

The whole video is worth a watch, brilliant stuff.

Armed with this rudimentary explanation of fluid dynamics we can try and understand what the various parts of the carburettor are for.

We will be looking at the carburettor that came with my c90 z2, a PB25A. It was made by Keihin, who have been making carburettors for Honda since the late 1950s. It is one of several designs used on the c90 over the years and this particular model of carburettor was only installed on the Z2 and ZZ models made in the late 1970s/early 1980s. The carbs used on the later cubs are similar in design but there is one important difference (which effects how the carburettor is adjusted) and this is explained in a later post.

Jets

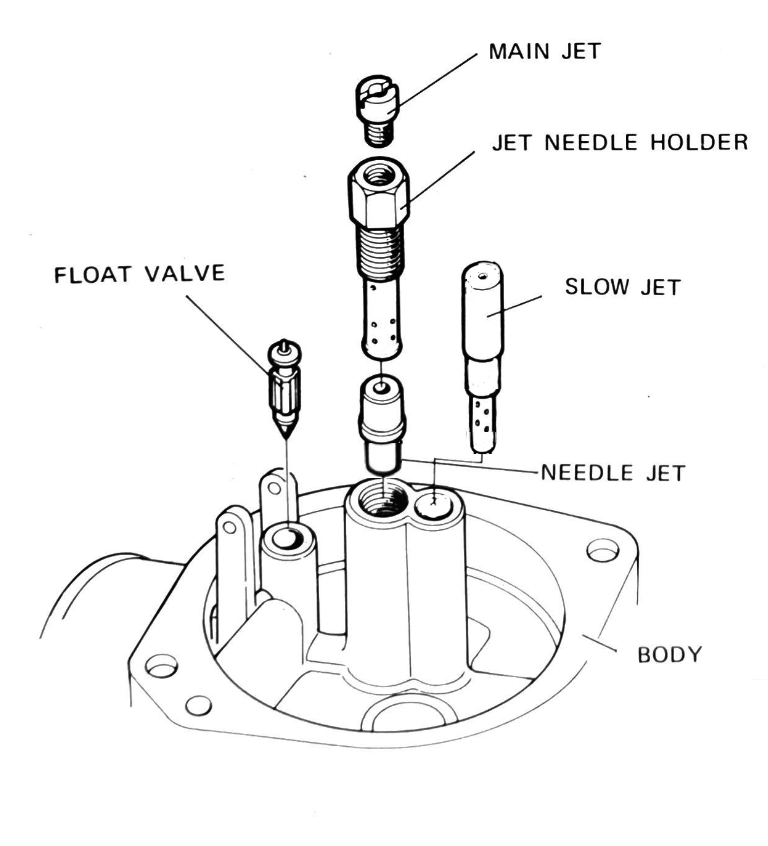

The air and fuel is metered through jets. Jets control the flow of a fluid (air or fuel) through an orifice that has been exactly drilled to a specified size. C90s have a needle jet, a main jet and a slow (pilot) jet.

Circuits

Fuel and air in this carburettor is controlled through two separate arrays of passages (known as circuits): the idle circuit which controls the mixture of fuel and air at low throttle speeds and the main circuit which controls the supply of fuel and air after the engine comes off idle.

Assembly

Replacement parts and seals are available for many older Honda carbs, including the one fitted to the C90z. It is generally recommended to stick to original Honda parts where possible, particularly the brass parts, as the aftermarket replacements are not always the correct size.

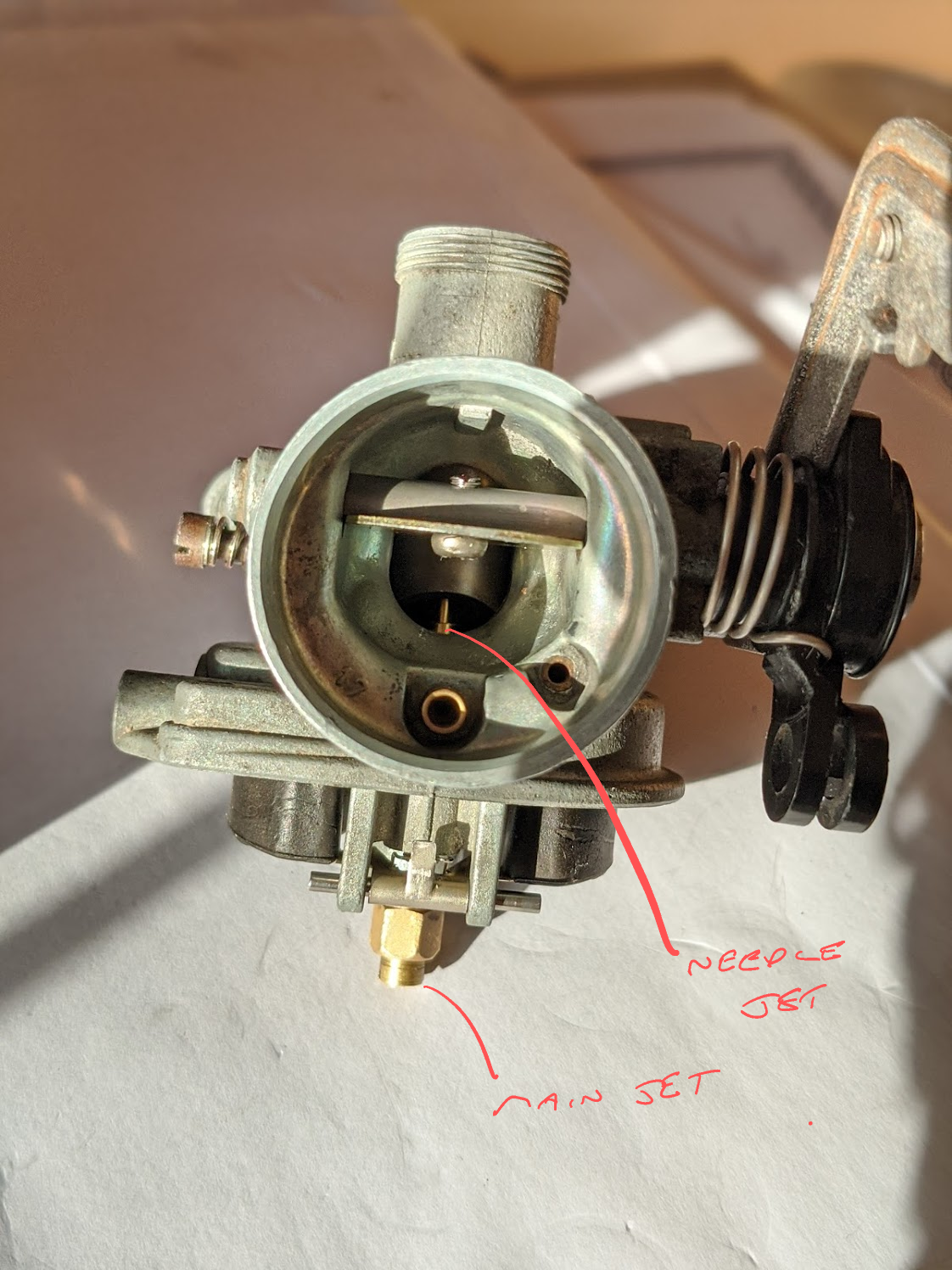

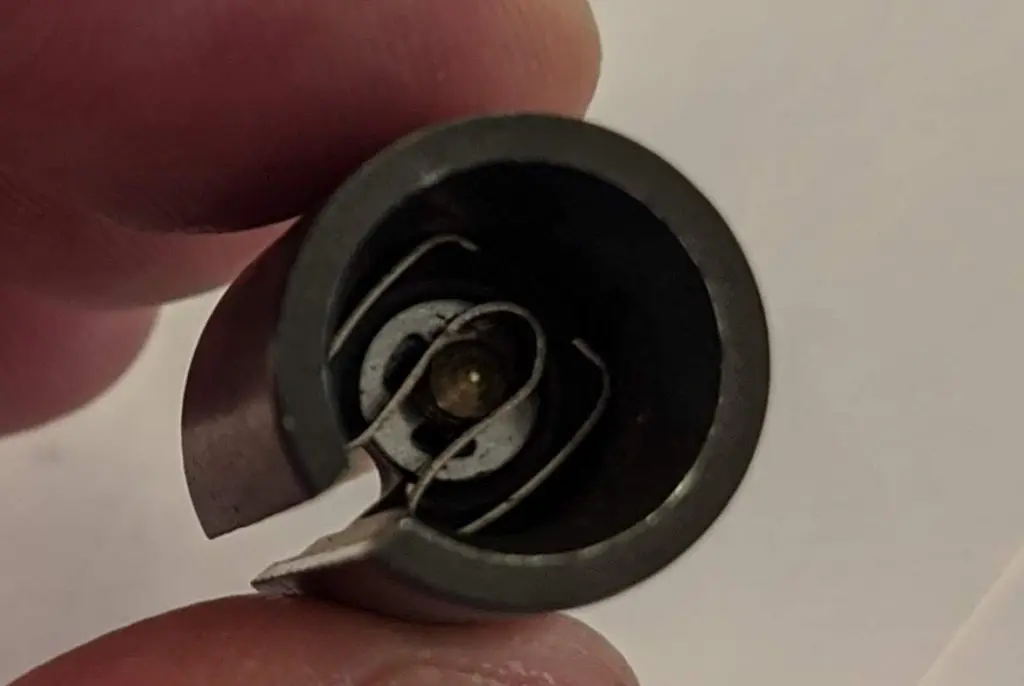

There is not a lot to say about fitting the parts: the first bit to go in is the needle jet, this is a push fit and can be popped in and out with a suitable sized wooden drift (the end of a wooden pencil for instance). Note that the orifices at each end of the needle jet are different sizes – the wider one points towards the top of the carburettor. On this model the circumference of the top part on the needle jet is slightly larger than the hole in the carburettor body, which prevents it going in the wrong way round, but apparently on other versions it is possible to get them in upside down

The main jet screws into the base of the main jet holder and the holder is then fitted into the carb body so that the main jet is sat in the chamber of fuel below and the top of the needle jet pokes into the venturi.

installed

One other thing to take care of is that the “W” clip that holds the jet needle in place must not obstruct the slot running the length of the slide. This slot engages with a lug in the throat of the carburettor (to prevent the slide rotating) and if the W clip catches on it the throttle sticks open. It took me an embarrassingly long time to work out that this was the problem when I got this wrong initially.

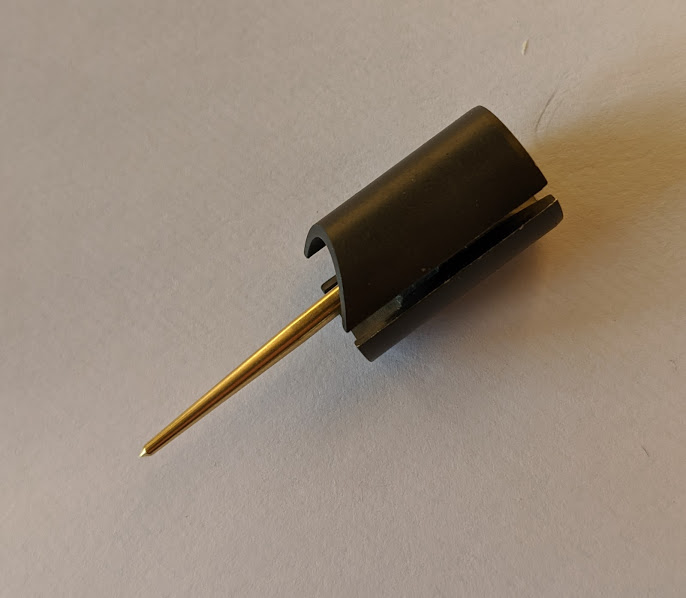

throttle slide and jet needle / W-clip installed

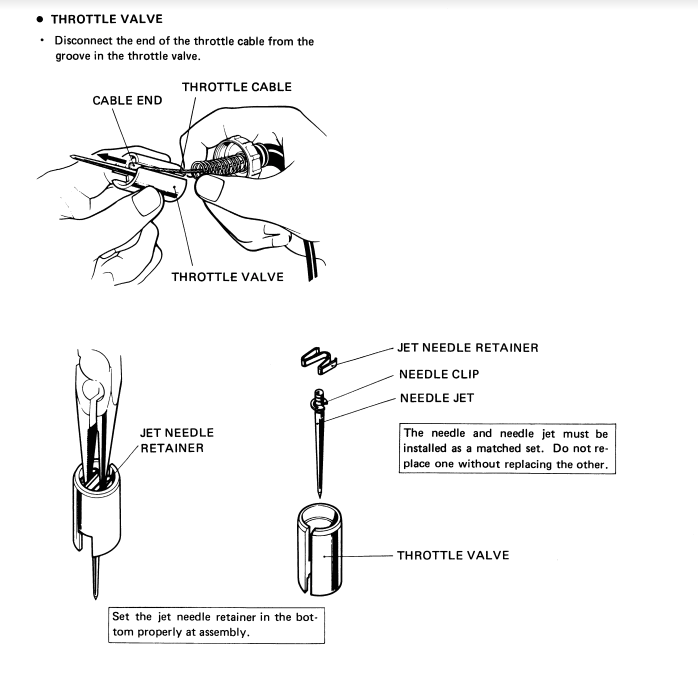

Here are the Honda instructions on assembly and disassembly of the slide and jet needle:

I’ll endeavour to explain how these bits work in the next thrilling instalment!

References

| 1 | strictly speaking, the correct terms are "fuel lean" and fuel rich". ⏎ |